Chain transmission type lifting pallet changer

A workbench, transmission type technology, applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve problems such as poor hydraulic cylinder sealing, workbench deflection problems, and easily damaged workbench components, etc. Synchronization problem, solving complex structure, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

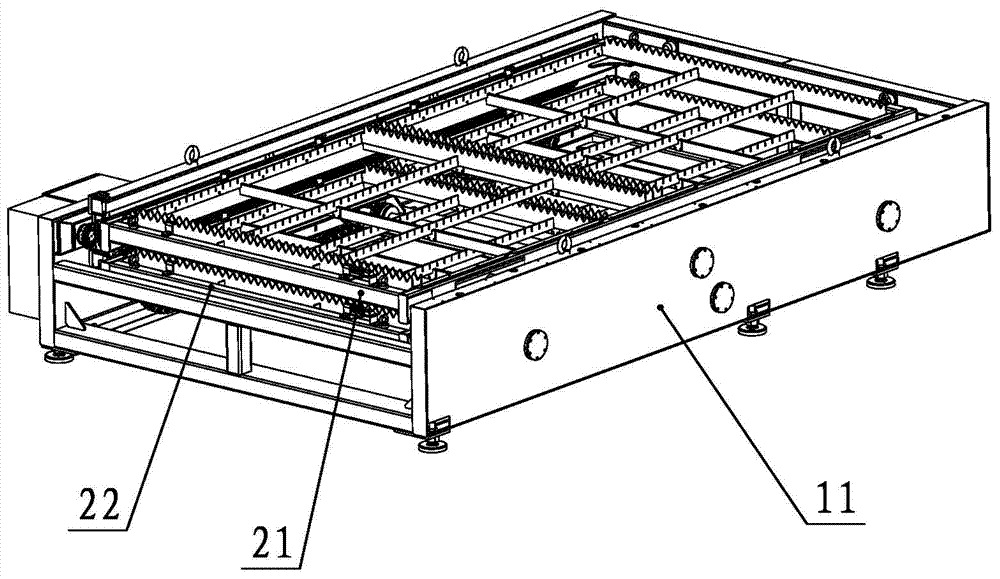

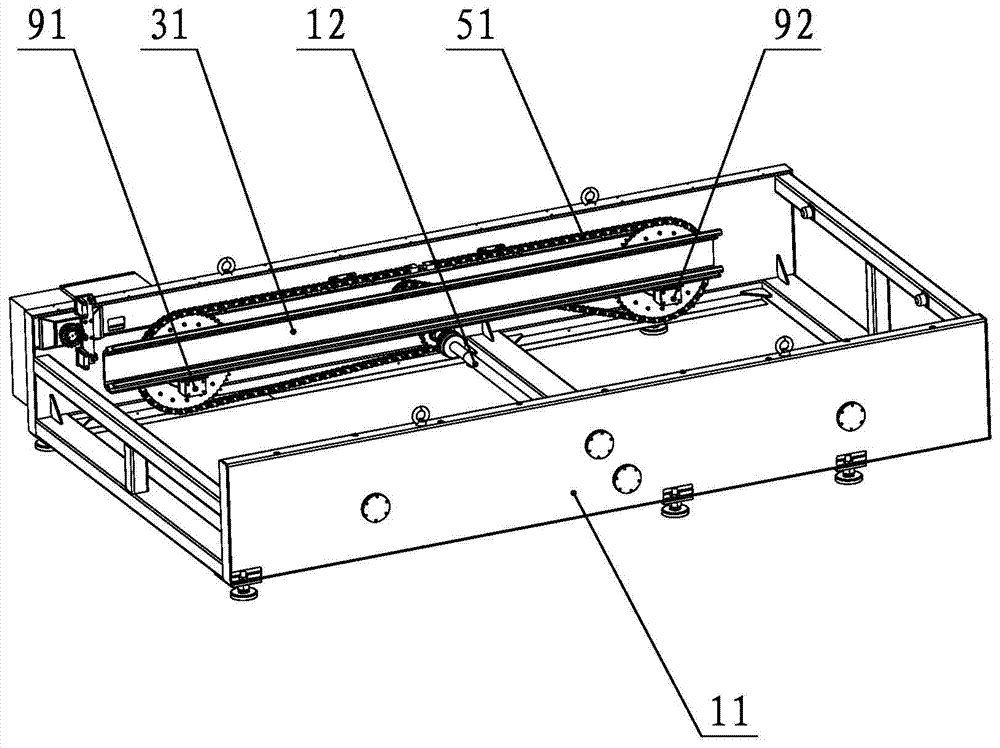

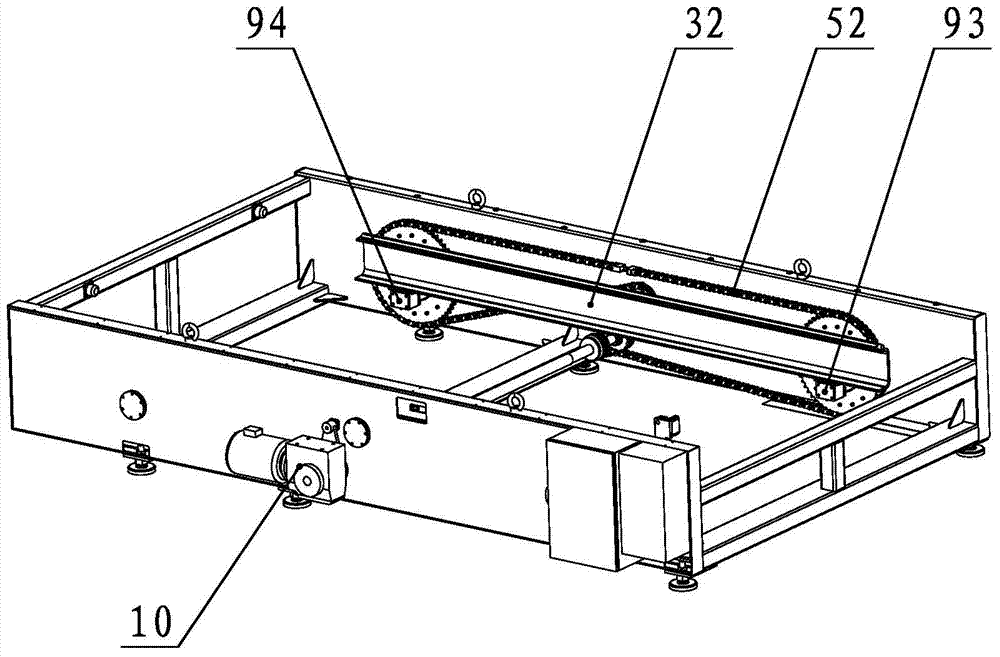

[0030] refer to Figures 1 to 5 , the chain-driven lifting exchange workbench provided by the present invention includes a base 11, a left sprocket lifting system and a right sprocket lifting system respectively installed on the symmetrical inner side of the base 11, and is used to connect the left sprocket lifting system and the right sprocket lifting system. The synchronous shaft 12 of the system, and the cutting table synchronously driven by the left sprocket lifting system and the right sprocket lifting system, the synchronous shaft 12 is driven by the motor 10 and the reducer.

[0031] Wherein, the left sprocket lifting system includes the left driven large sprocket 61 / 62 installed on the two ends of the left side plate of the base 11 through bearings, and the left drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com