Clamping device and method for ensuring equal protruding lengths at both ends of a core bolt

A core bolt and clamping device technology, which is used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the extension length is not easy to grasp, the length of the extension at both ends of the core bolt is different, etc. Reduce operation steps and improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

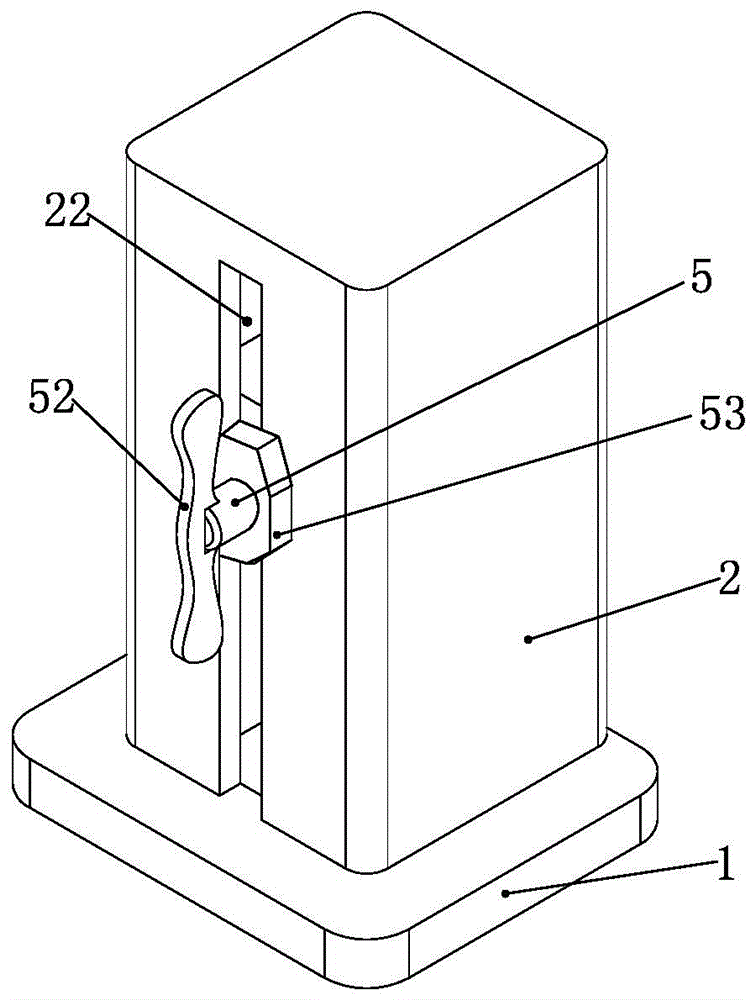

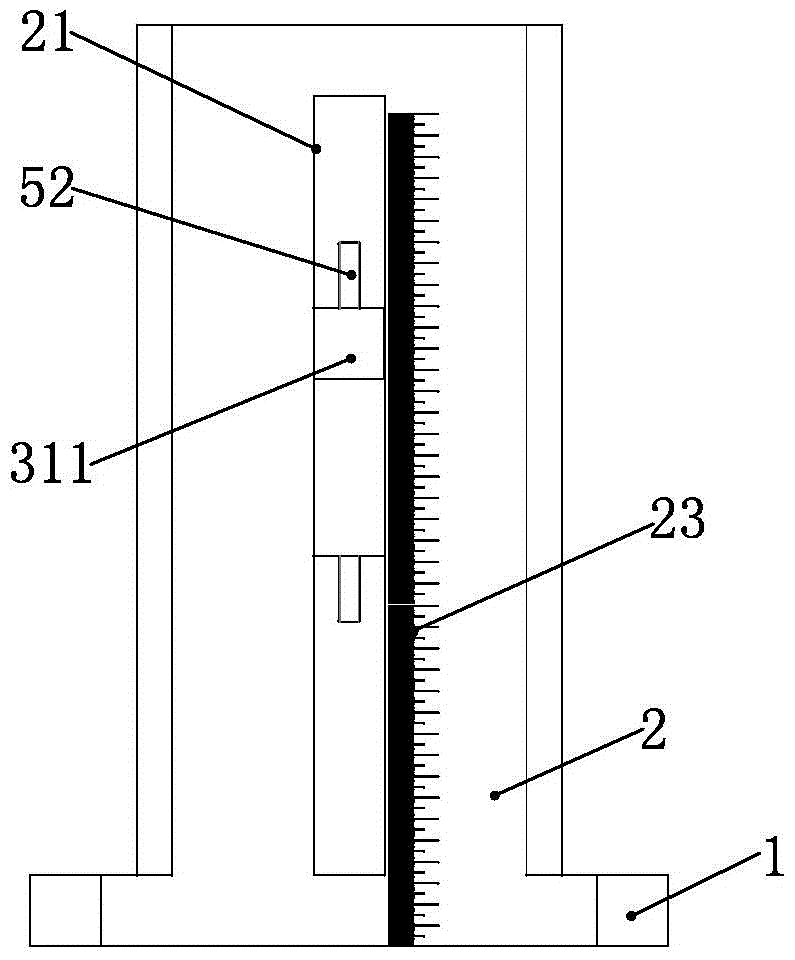

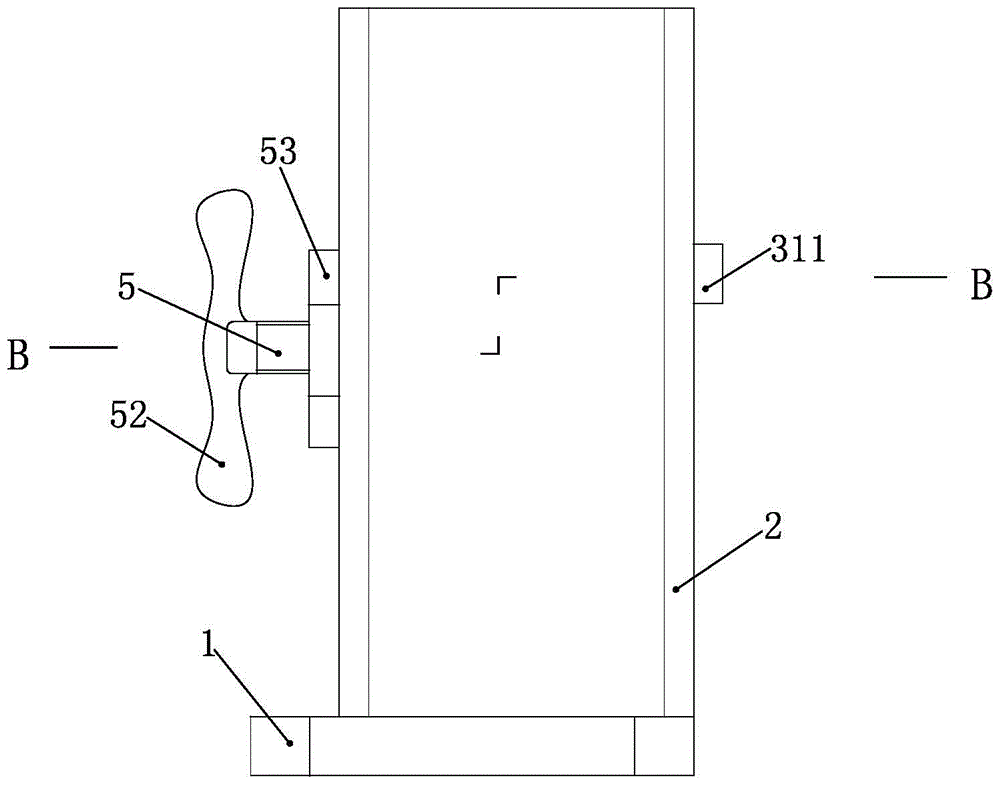

[0034] Such as Figure 1 to Figure 5 As shown, the present invention provides a clamping device for ensuring that both ends of a core-through bolt have equal extension lengths. It includes a magnetic base 1 on which axially arranged through holes 12 are provided.

[0035] A housing 2 is vertically arranged on the base 1, and a first cavity 24 communicating with the through hole 12 is provided inside the housing 2, and first grooves communicating with the first cavity 24 are symmetrically provided on two opposite sides of the housing 2 Holes 21 and the second slot 22, the outer surface of the housing 2 on one side of the first slot 21 is provided with a scale 23, in a specific embodiment, as figure 2 As shown, the zero mark line of the scale 23 is flush with the bottom surface of the base 1. In specific use, when the base 1 is in contact with the lower flange, it is ensured that the zero mark line of the scale 23 starts from the end face of the lower flange.

[0036] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com