Core box

A core box and core technology, applied in the field of geological exploration container tools, can solve problems such as careless operation, unstable placement, and bulky volume, and achieve the effects of avoiding idleness and waste, excellent sealing performance, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

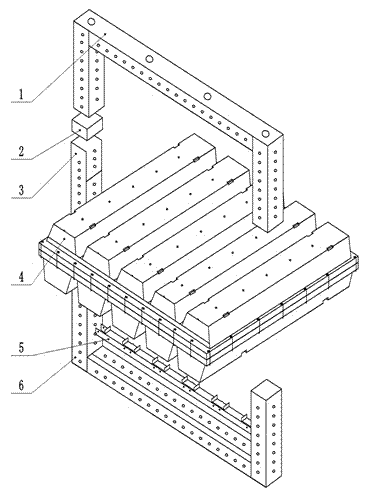

[0062] When the core box is simply stacked, such as Figure 12 to Figure 16 As shown, only the cover groove and the bottom groove of the core box 4 are simply combined, and the positioning, locking and code frame combination mechanism is not used.

[0063] The cover slot can choose the bottom slot with the card code positioning convex to turn it into a cover slot, thereby increasing the interchangeability of parts and making the cover slot and the bottom slot common. And when the core box function is further assembled, the compact and stable performance of the core box can be increased by placing the card code locator 5 and the positioning connection of the upper hoop code frame, and the cover groove without the card code positioning protrusion can also be selected to increase the distinction. Choose a single-cell or multi-cell body to avoid the core tank from being turned over due to misjudgment and reduce manual operation errors.

[0064] After matching the cover groove and...

Embodiment approach 2

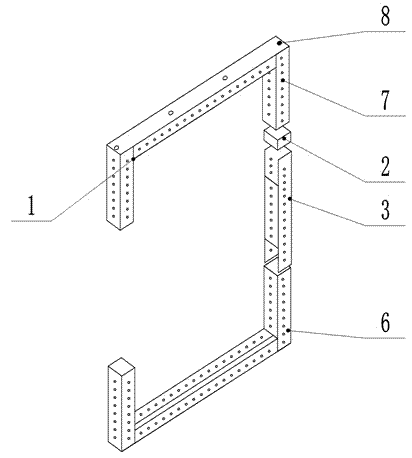

[0067] Such as Figure 17 As shown, in this state, the core box as a whole is used as a single-layer frame code for fastening.

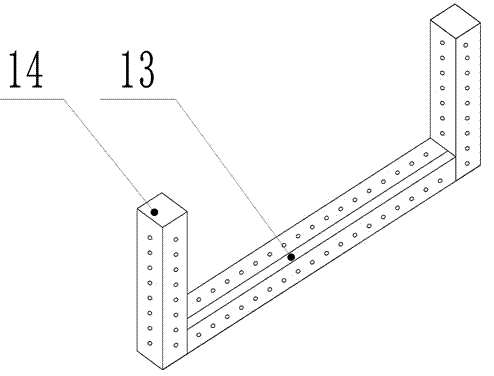

[0068] Remove the booster pad 2, first engage the card code locator 5 with the groove of the lower hoop frame 6, and pay attention to align the positioning holes 18 of the card code locator 5 with the multiple pairs of openings on the two side walls of the lower hoop frame 6. Align the holes of the locating connecting pins that are worn, and fix them with the tail hook pin 25 or other connectors. Next, align the casing 20 of the height-adjustable connector 3 with the frame columns 14 at both ends of the lower hoop frame 6 and insert it. At this time, the casing opening 19 is turned inward. Then the bottom groove of the core box 4 is placed on the lower hoop code frame 6, the core box 4 can be a single groove body or a multi-cell body, pay attention to the card code positioning protrusion 10 on the bottom groove and the card code locator 5 Rock core...

Embodiment approach 3

[0072] Such as Figure 17 As shown, in this state, the core box as a whole is used as a single-row multi-layer stacking connection.

[0073] First, engage the card code locator 5 with the groove of the lower hoop frame 6, pay attention to align the positioning hole 18 of the card code locator 5 with the multiple positioning connecting pins opened on the two side walls of the lower hoop frame 6 The holes are aligned and fixed with tail hook pin 25 or other connectors. Next, align the casing 20 of the height-adjustable connector 3 with the frame columns 14 at both ends of the lower hoop frame 6 and insert it. At this time, the casing opening 19 is turned inward. Then the bottom groove of the core box 4 is placed on the lower hoop code frame 6, the core box 4 can be a single groove body or a multi-cell body, pay attention to the card code positioning protrusion 10 on the bottom groove and the card code locator 5 Rock core groove limit platform 17 coordinates location.

[0074]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com