Chemical storage tank

A storage tank and chemical technology, applied in the direction of tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of difficulty in taking out, increased viscosity of chemicals, slow flow of storage tanks, etc., and achieves the effect of improving heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

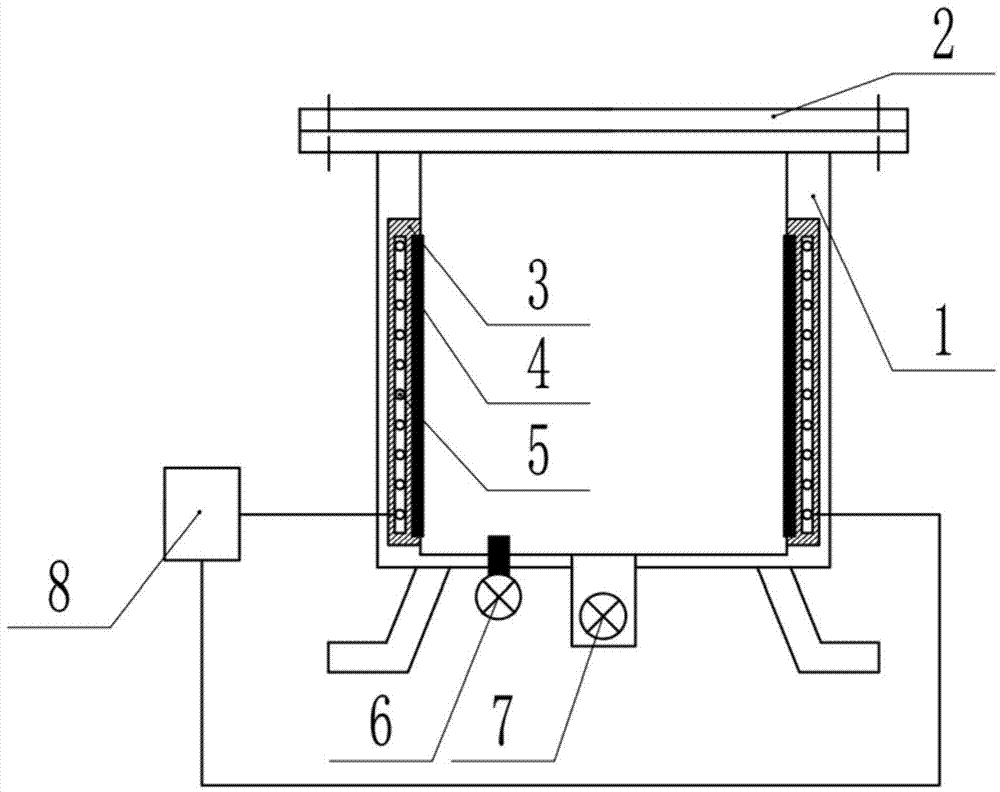

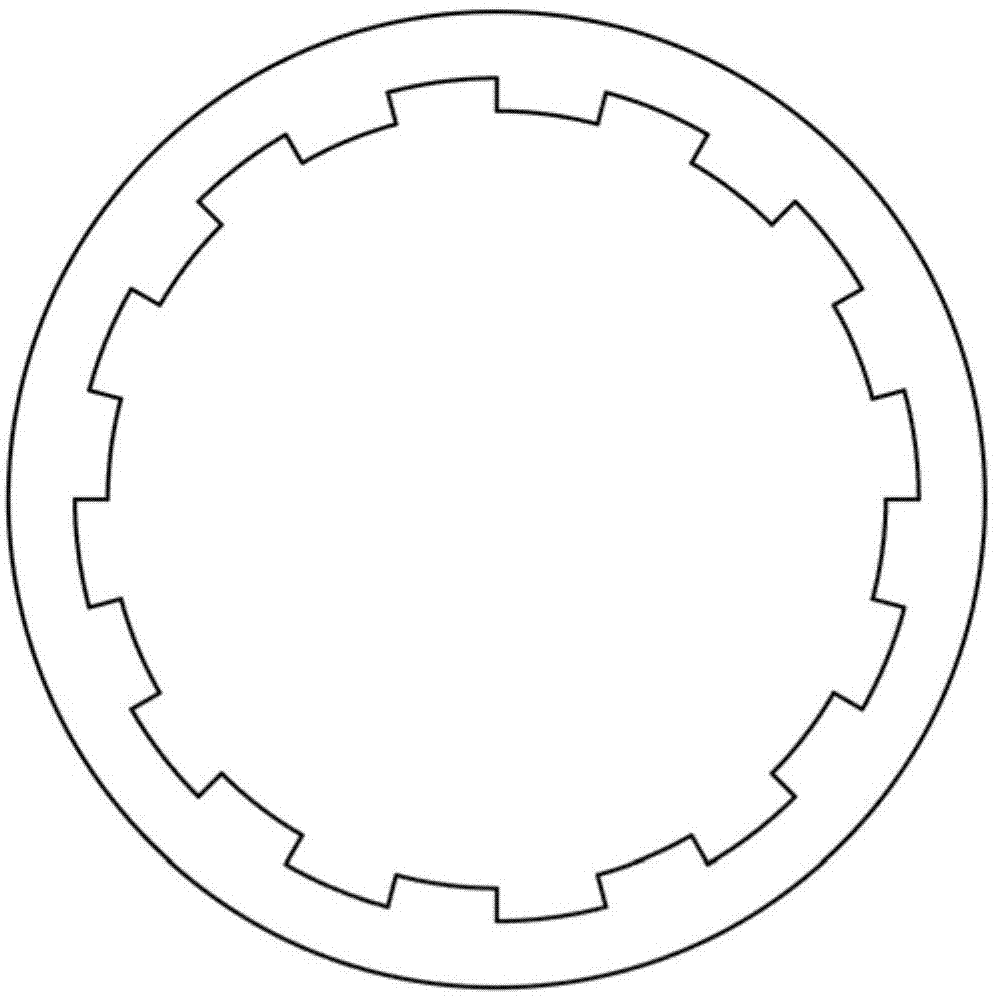

[0016] A chemical storage tank, comprising a tank body 1, the upper part of the tank body 1 is provided with a cover 2 that is movably connected thereto, the side wall of the tank body 1 is provided with an installation card slot, and a heat insulation device is installed in the installation card slot The felt block 3, the interior of the heat insulation felt block 3 is a hollow structure, and a heating wire 5 is arranged inside, and one side of the tank body of the heat insulation felt block 3 is a groove, and a phase change insulation layer 4 is arranged in the groove, and the phase change The inner side of the insulation layer 4 is provided with a plurality of bosses along the circumferential direction; the bottom of the tank body 1 is provided with a discharge port 7 fixed thereto, and a thermometer 6 is also provided.

[0017] In this embodiment: the heating wire 5 uses an AC power supply 8 as a power supply; the heat insulation felt block 3 is made of an airgel blanket; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com