Continuous sewing and steam-ironing device

A technology of steam ironing and compounding device, which is applied in sewing equipment, textile and papermaking, fabric surface trimming, etc., to achieve the effect of good performance, good sewing effect and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

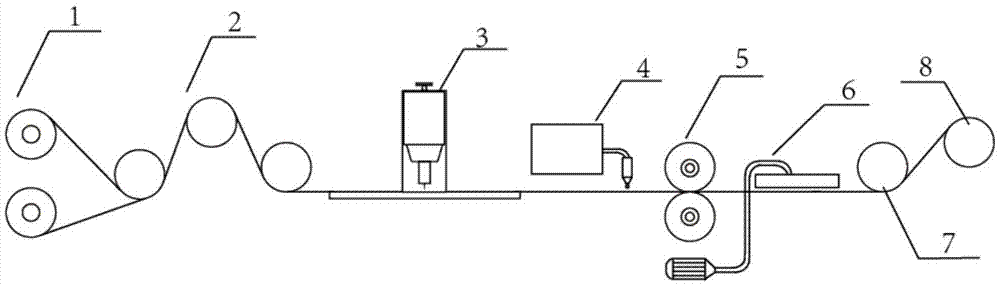

[0026] See attached figure 1 , a continuous sewing steaming and ironing device, which consists of two cloth roll supports 1, a cloth composite device 2, an automatic sewing machine 3, a spraying device 4, a hot pressing roller 5, a cooler 6, a tension roller 7 and a cloth winding roller 8 arranged in sequence ;

[0027] The cloth composite device 2 is composed of three transmission rollers; the three transmission rollers are arranged in a character shape; two are on the same horizontal plane, and one is above; among the three transmission rollers, two transmission rollers are located on the same horizontal plane . The two layers of cloth are pulled out from the cloth roll support respectively, combined on the first driving roller, and pasted together; then pass through the second and third driving rollers; finally, the tightly fitted two layers of cloth are stitched by sewing equipment deal with.

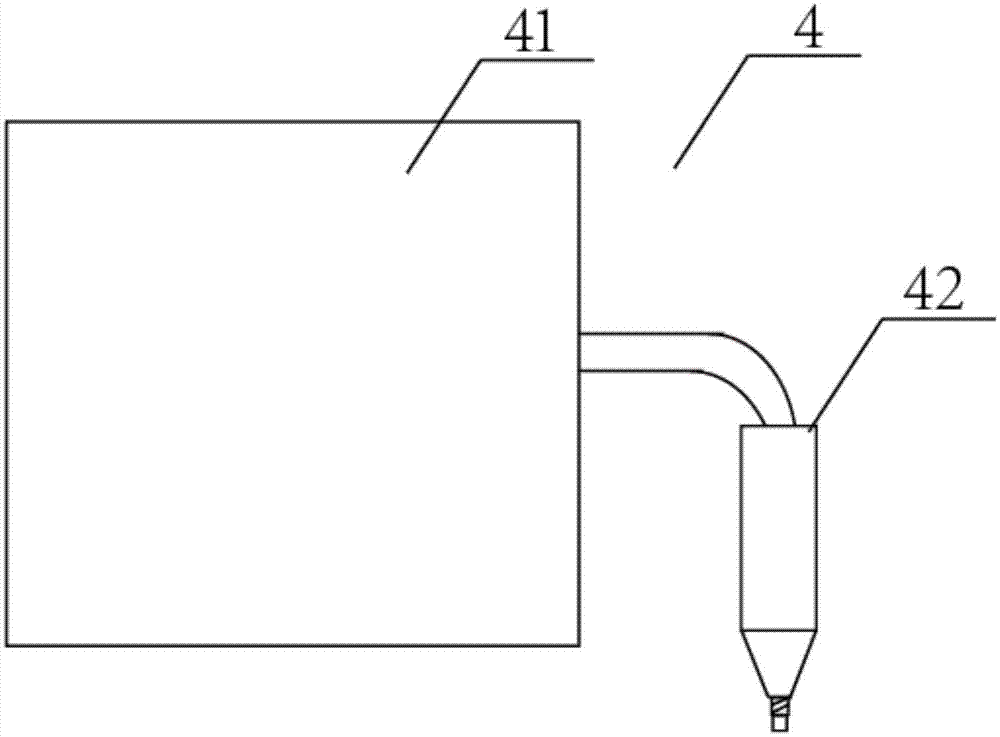

[0028] Described spray equipment 4 comprises the water tank 41 and nozzle 42...

Embodiment 2

[0032] The continuous sewing steaming and ironing device is composed of two cloth roll supports, cloth compounding device, automatic sewing machine, spraying equipment, hot pressing roller, cooling device, tension roller and cloth winding roller arranged in sequence;

[0033] The cloth composite device is composed of three transmission rollers; the three transmission rollers are arranged in a square shape; two are on the same horizontal plane, and one is above;

[0034] The spraying equipment includes a water tank and a nozzle; the nozzle is a cylindrical straight hole nozzle;

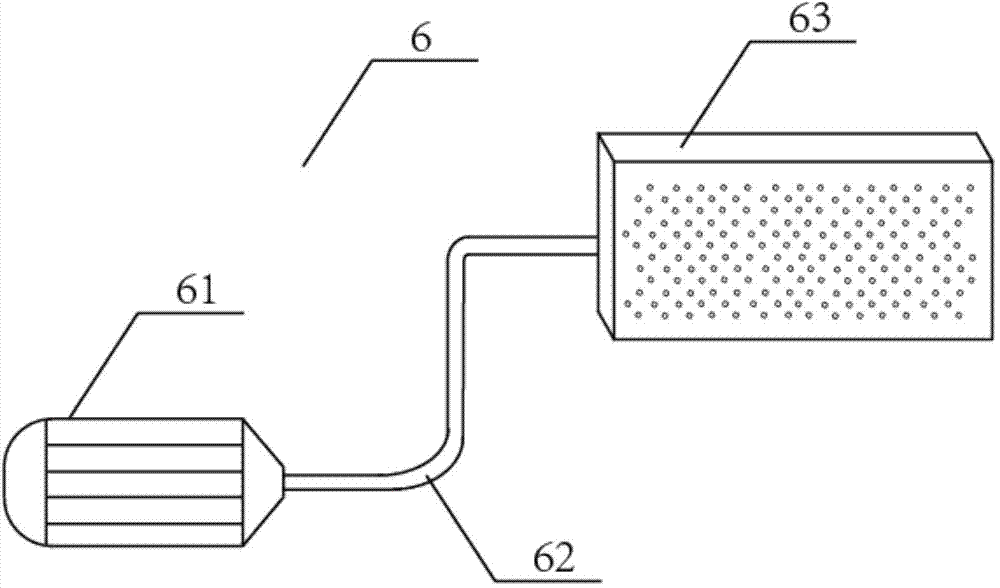

[0035] The cooler includes a hollow steel plate and a 50W air blower; the air outlet of the air blower communicates with the hollow steel plate through an air pipe; the downward side of the hollow steel plate is provided with a blowing hole. The diameter of the air blow hole is 3 cm.

[0036]According to the continuous sewing and steaming device of this embodiment, two cloth roll holders place cloth r...

Embodiment 3

[0038] According to the continuous sewing and steaming device of Embodiment 1, two cloth roll holders place cloth rolls respectively, and the material of the cloth rolls is vinylon cloth; the cloth threading treatment is performed first, so that the cloth forms continuity on the system, and the running speed of the cloth is adjusted as follows: 35m / min; then start the automatic sewing process: the cloth is dragged out from the two cloth roll holders respectively to form two cloth layers; then the two cloth layers are overlapped after passing through the cloth composite device; then the overlapped cloth is on the automatic sewing machine Stitching; then the stitched cloth passes under the spraying equipment, and starts to sprinkle water. Specifically, water is put into the water tank and poured on the cloth through the nozzle; the sprayed cloth passes through the hot pressing roller, and is heated at 80°C and 0.08MPa pressure. Next, the water volatilizes, the surface of the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com