A pulping equipment with material-liquid separation and secondary air vortex crushing

A technology of secondary air and crushed materials, applied in the separation of raw materials, fiber raw materials, and fiber raw material processing, etc., can solve the problems of high energy consumption and low efficiency, and achieve the effects of maintaining stability, eliminating shaking and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

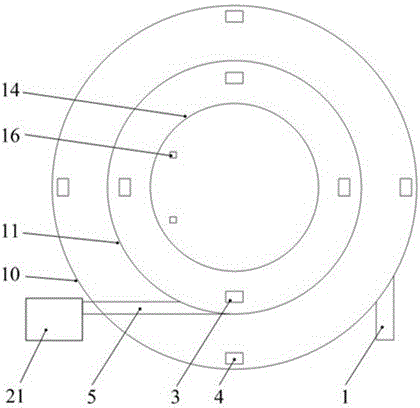

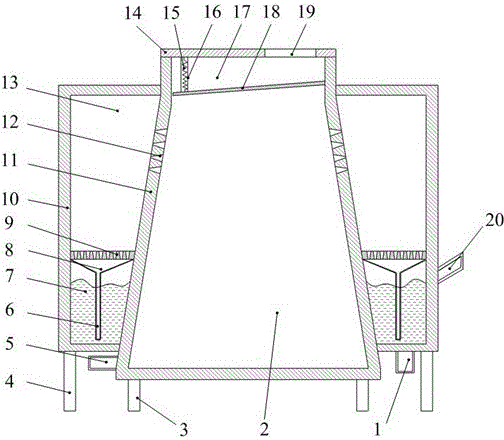

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a pulping equipment of the present invention with material-liquid separation and secondary air vortex crushing mainly includes a feeding device, a vortex crushing device, and a slurry generating device.

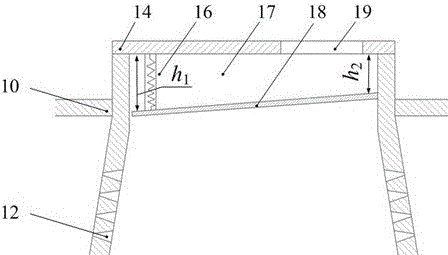

[0025]The feeding device is mainly composed of a feeding port 19, a spring 15, a spring protective cover 16 and a buffer and a sealing plate 18. The feeding port 19 is opened on the top cover 14, and the upper and lower ends of the spring 15 are respectively connected to the top cover 14 and the buffering and sealing plate. The sealing plate 18 is covered with a spring protective cover 16 on the outside of the spring 15, and the top cover 14, the buffer and sealing plate 18 and the upper part of the inner cone 11 enclose the feeding buffer zone 17.

[0026] The buffer and sealing plate 18 is a disc-shaped structure with a certain slope, which can realize the blanking slowly entering the primary vortex c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com