A kind of synthesis method of prefabricated steel cage

A synthesis method and steel cage technology, applied in the direction of manufacturing tools, ceramic molding machines, structural elements, etc., can solve problems such as labor-consuming and time-consuming, achieve high recycling rate, solve the effects of labor-consuming and time-consuming construction, and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

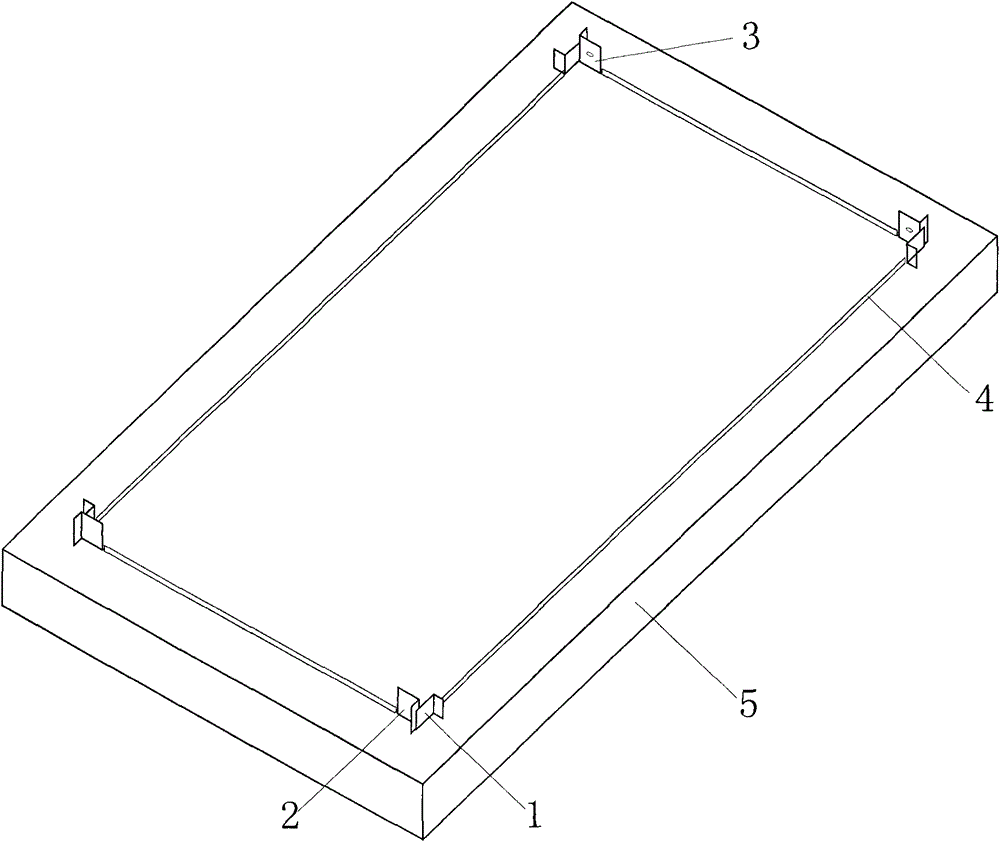

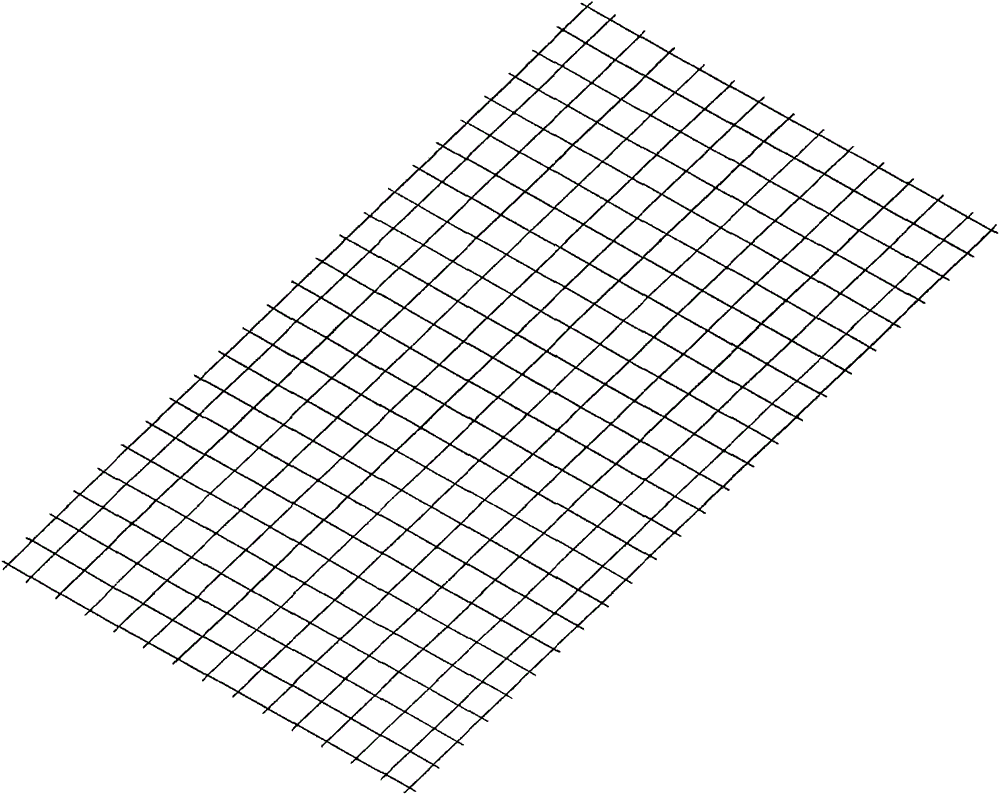

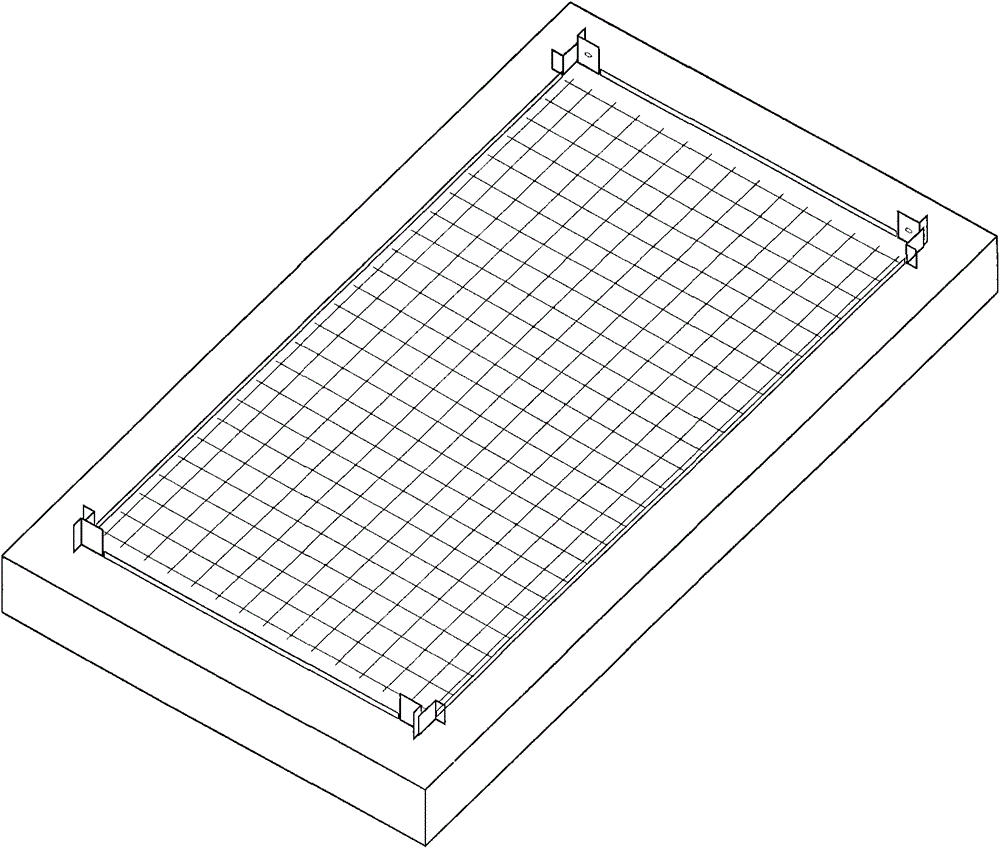

[0035] Use the steel bar straightening and cutting machine to straighten the coiled circular steel bars and cut them into the length required by the design to obtain steel bars of different sizes. The steel bars are welded by a steel bar spot welder to form a steel bar upper sheet (see figure 2 ) and mesh under the reinforcement (see figure 2 ). First synthesize the mold in the steel cage (see figure 1 ) and arrange the mesh under the reinforcement (see figure 2 ),Such as image 3 shown. On one side of the steel sheet with a width of 260mm, weld the bent protruding stirrups and ring-shaped stirrups to make the protruding stirrup frame (see Figure 7 ), where the stirrup spacing is 200mm. Weld the prefabricated raised stirrup frame on the four sides of the mesh under the steel bar (see Figure 7 ), and finally weld the upper mesh of the steel bar to the frame of the prefabricated raised stirrup (see Figure 10 ), the formed prefabricated reinforcement cage 1 can be o...

Embodiment 2

[0037] Use the steel bar straightening and cutting machine to straighten the coiled circular steel bars and cut them into the length required by the design to obtain steel bars of different sizes. The steel bars are welded by a steel bar spot welder to form a steel bar upper sheet (see figure 2 ) and mesh under the reinforcement (see figure 2 ). First synthesize the mold in the steel cage (see figure 1 ) and arrange the mesh under the reinforcement (see figure 2 ),Such as image 3 shown. Weld the bent concave stirrups and ring-shaped stirrups on one side of the steel sheet with a width of 260mm to make the frame of the concave stirrups (see Figure 8 ), where the stirrup spacing is 200mm. Weld the prefabricated concave stirrup frame on the four sides of the mesh under the steel bar (see Figure 8 ), and finally weld the upper mesh of the steel bar to the frame of the prefabricated concave stirrup (see Figure 11 ), the formed prefabricated reinforcement cage 2 can b...

Embodiment 3

[0039] Use the steel bar straightening and cutting machine to straighten the coiled circular steel bars and cut them into the length required by the design to obtain steel bars of different sizes. The steel bars are welded by a steel bar spot welder to form a steel bar upper sheet (see figure 2 ) and mesh under the reinforcement (see figure 2 ). First synthesize the mold in the steel cage (see figure 1 ) to arrange the mesh under the reinforcement (see figure 2 ),Such as image 3 shown. Weld the bent ring stirrup on one side of the steel sheet with a width of 260mm to make the frame of the ring stirrup (see Figure 9 ), where the stirrup spacing is 200mm. Weld the prefabricated ring stirrup frame on the four sides of the mesh under the steel bar (see Figure 9 ), and finally weld the reinforcement mesh to the frame of the prefabricated ring stirrup (see Figure 12 ), the formed prefabricated reinforcement cage 3 can be obtained (see Figure 15 ), sent to synthesize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com