A kind of multistage centrifugal pump

A centrifugal pump and pump body technology, applied in the direction of pumps, pump control, pump components, etc., can solve the problems of poor sealing performance, low output efficiency, and easy formation of gas binding in multi-stage centrifugal pumps, so as to reduce liquid leakage, Improve the sealing effect and ensure the effect of concentricity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

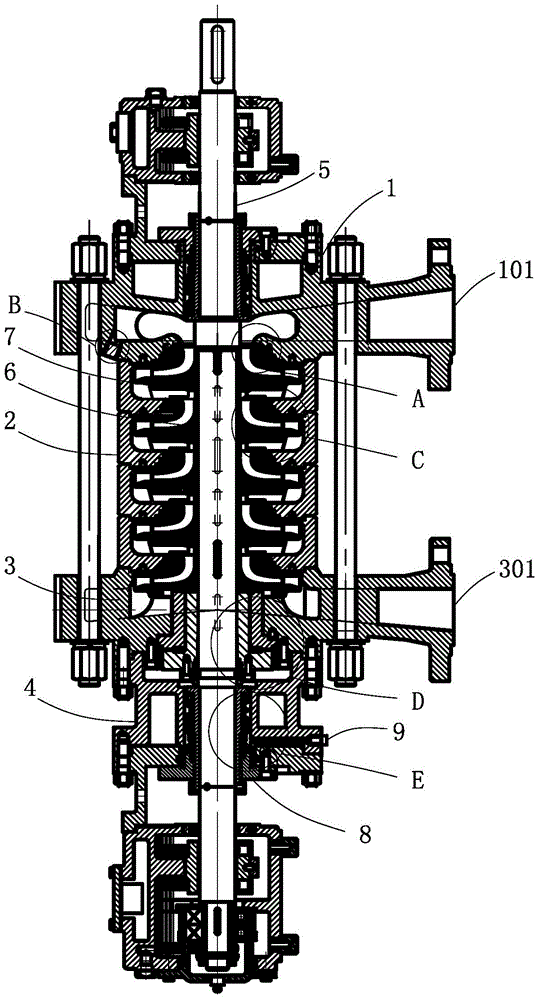

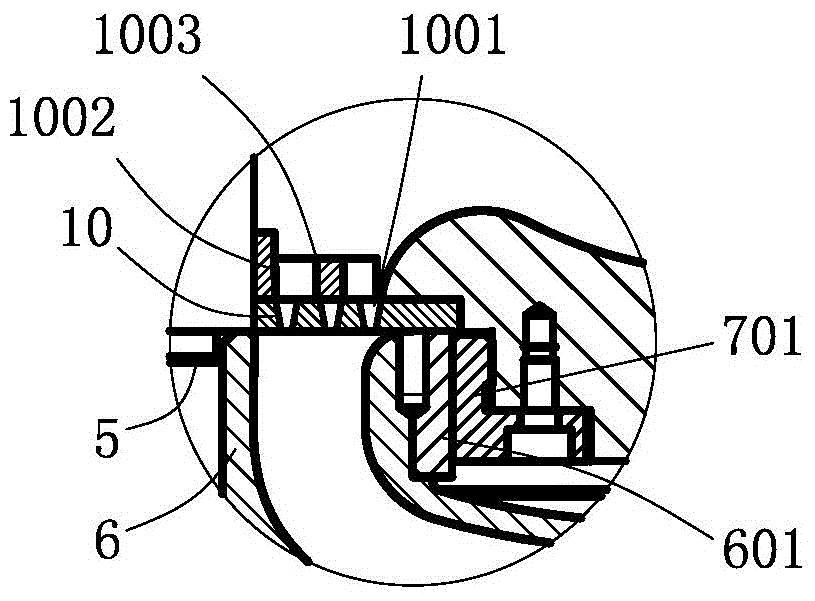

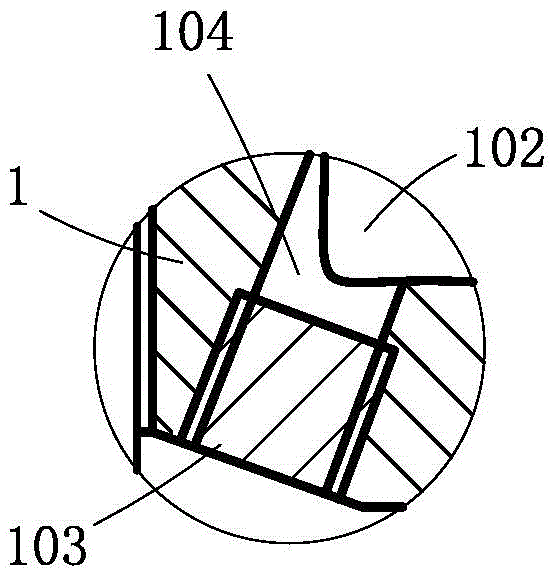

[0035] like Figure 1 to Figure 7 Commonly shown, the present invention provides a novel multi-stage centrifugal pump, including a pump body, in which a transmission shaft 5 is installed for rotation, and the pump body includes a suction section 1, a middle section 2 and a discharge section 3, and the middle section 2 is arranged on the suction section 1 and the discharge section 3, the suction section 1 is provided with a suction port 101, the discharge section 3 is provided with a discharge port 301, and a number of impellers 6 are fixedly installed on the transmission shaft 5 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com