High-strength oil seal

A sealing oil and high-strength technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of easy wear of rubber sealing lips, large friction coefficient, and leakage of lubricating oil, and achieve good automatic compensation ability and extended The effect of service life and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

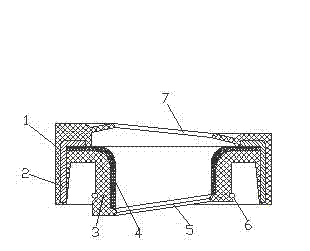

[0018] The accompanying drawing is a structural schematic diagram of the present invention. The high-strength sealing oil seal of the present invention includes a rubber body, a skeleton 2, a sealing lip 4 and a dust-proof lip 7. A sealing lip 5 is provided on the side of the sealing lip 4 where the oil comes from. The oil side refers to the lubricating oil side that needs to be sealed; the sealing lip 5 and the dustproof lip 7 are both internal helical structures, and the internal helical structure of the sealing lip 5 and the internal helical structure of the dustproof lip 7 The deployment direction is opposite, and the deployment direction of the internal helical structure of the dust-proof lip 7 is the same as the direction of rotation of the sealed shaft due to the oil incoming direction.

[0019] In this embodiment, the sealing lip 5 is integrally formed with the rubber body, the sealing lip 4 is made of polytetrafluoroethylene and its outer circle is bonded to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com