Novel drying equipment

A drying equipment and a new type of technology, applied in the direction of drying chamber/container, drying gas arrangement, local stirring dryer, etc., can solve the problems of uneven air flow, slow drying speed, large wind resistance of hot air, etc., to improve drying quality and improve Accuracy, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

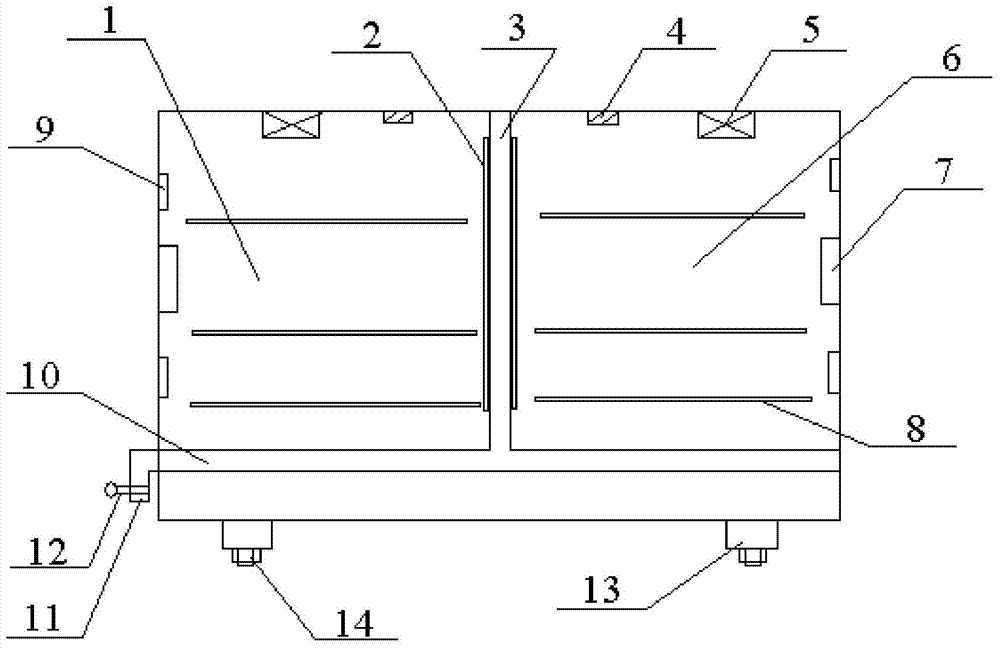

[0016] Attached below figure 1 The present invention will be further described with reference to specific embodiments.

[0017] The present invention provides a drying device, which is characterized in that it includes a left box 1 and a right box 6, the left box 1 and the right box 6 are symmetrically distributed, and inside the left box 1 and the right box 6 Symmetrically equipped with temperature sensor 4, balanced hot air box 5, fan 7 and heater 9, can achieve the purpose of precise temperature control, improve the accuracy of detection, improve the drying quality of products, save energy, and the middle position of the box is equipped with a moisture collector The device 2 and the dehumidification box 3, the left box 1 and the right box 6 are provided with a multi-layer drying rack 8; the lower part is provided with a dehumidification tank 10; the heater 9 and the temperature sensor 4 are connected with the control system connected, the blower fan 7 is connected to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com