Automatic condensing fin cleaning device and air conditioner with same

A technology for automatic cleaning and cleaning devices, applied in cleaning heat transfer devices, air conditioning systems, flushing, etc., can solve the time-consuming and labor-intensive problems of manual cleaning, and achieve the goals of solving time-consuming and labor-intensive tasks, improving reliability and service life, and reducing manual maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

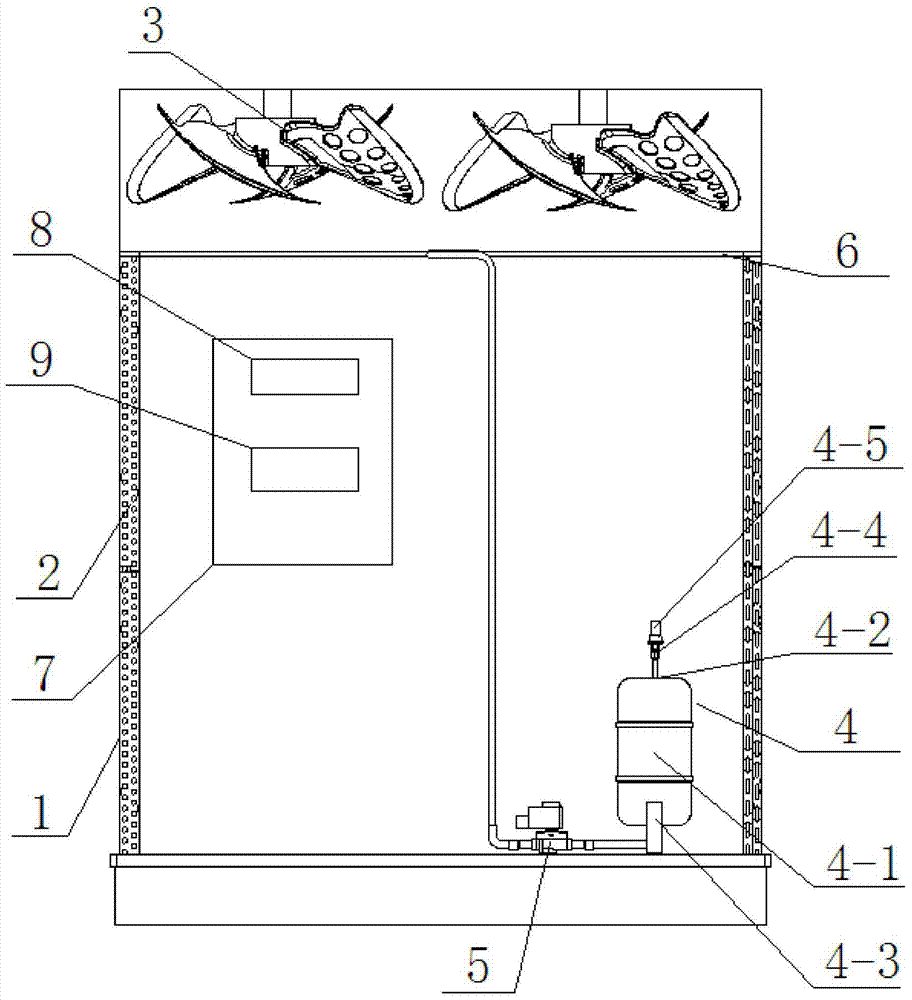

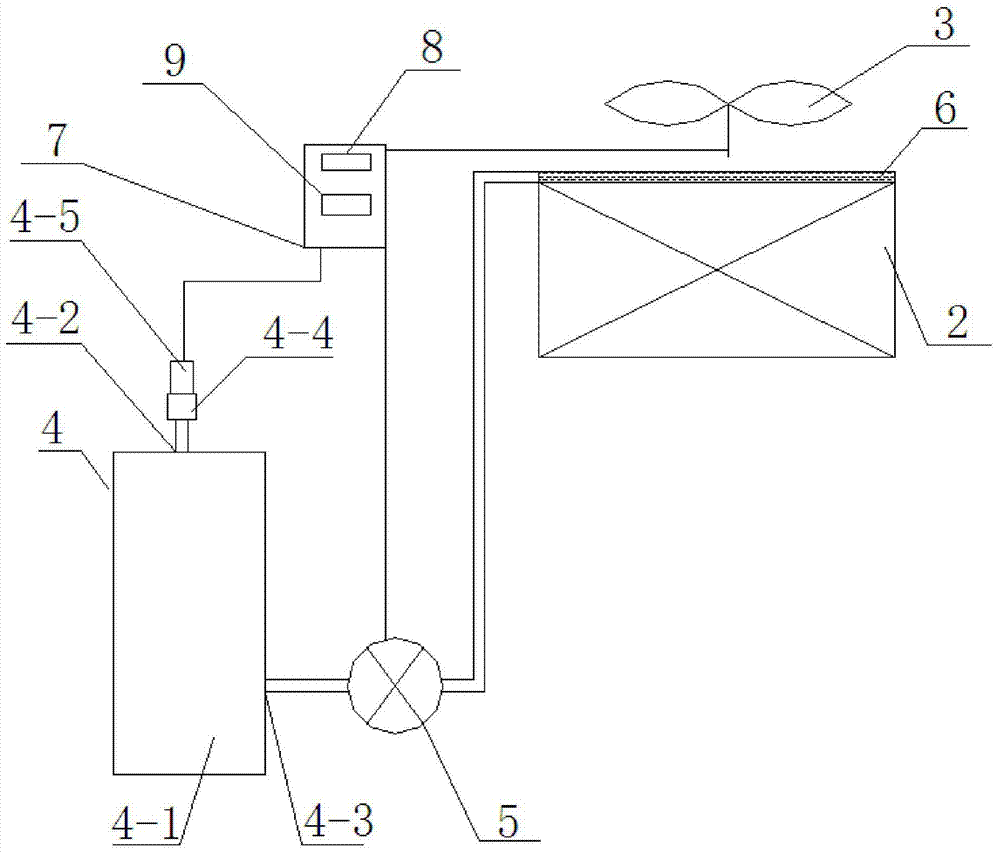

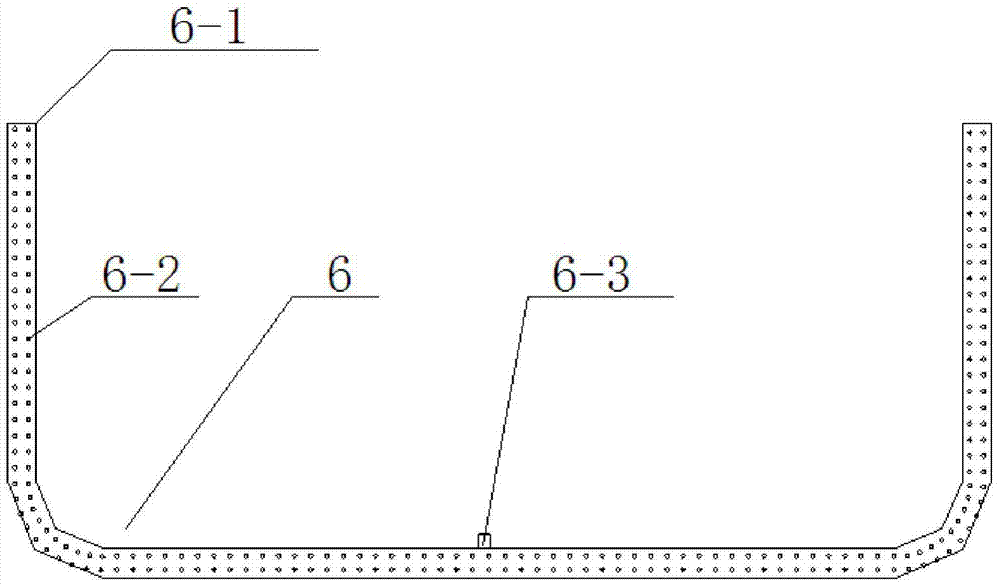

[0029] Such as figure 1 , figure 2 As shown, the present invention includes a liquid storage device 4, a solenoid valve 5, a spray head device 6, and a control box 7. The liquid storage device 4 is provided on the air-conditioning outer casing 1, and the liquid storage device 4 is connected to the station through a pipe. The solenoid valve 5 is connected to the spray head device 6 through a pipeline, the spray head device 6 is arranged on the fin heat exchanger 2, and the solenoid valve 5 is electrically connected to the control box 7, The control box 7 controls the opening and closing of the solenoid valve 5 and adjusts the opening size of the solenoid valve 5.

[0030] The liquid storage device 4 includes a liquid storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com