Technology for making engine physical anatomy teaching tool

A manufacturing process and engine technology, applied in educational appliances, teaching models, instruments, etc., can solve problems such as temperature increase, damage to lubrication, ablation of bearings, etc., and achieve the effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

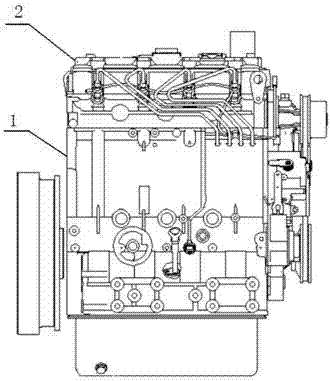

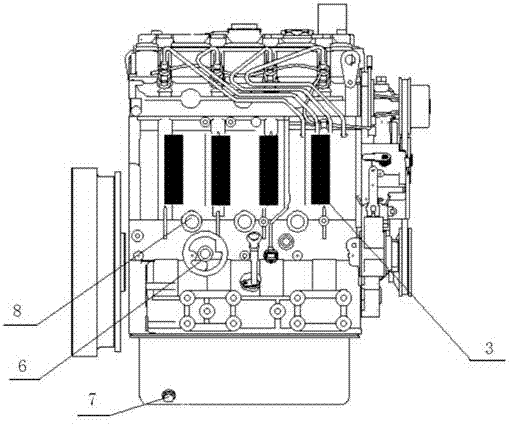

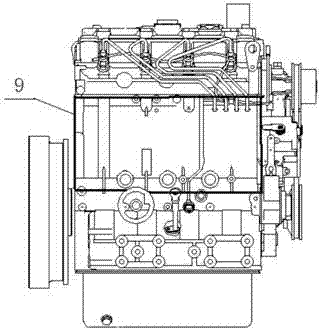

[0044] Embodiment 1: a kind of engine physical anatomy teaching aid manufacturing process, comprises the following steps:

[0045] (1) Cleaning of engine block and cylinder head.

[0046] The cleaning process of the engine body is as follows: put the body 1 into a sodium hydroxide solution and boil, wash off the oil stain on the surface of the body 1, rinse the body 1 with clean water, dry the body 1 with a dust blower, put it in a hot air oven, Take out the body 1 after baking with hot air at a constant temperature of 80 degrees Celsius for 2 hours.

[0047] The cleaning process of the cylinder head 2 is as follows: the cylinder head 2 is cleaned of oil stains with gasoline, and after being blown dry, sandblasting is powered by high-pressure air to remove the dirt attached to the cylinder head 2.

[0048] (2) Combination of engine block and cylinder head.

[0049] The engine cylinder head 2 and the body 1 are connected by cylinder head bolts to form a whole, and a 1mm thick s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com