A/D converter input stage

An analog-to-digital converter, input stage technology, applied in the direction of analog-to-digital converter, analog conversion, code conversion, etc., can solve problems such as increasing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The examples in the figures are schematic. It should be noted that in different drawings, similar or identical components in various embodiments are represented by identical or similar symbols, and only the first number changes.

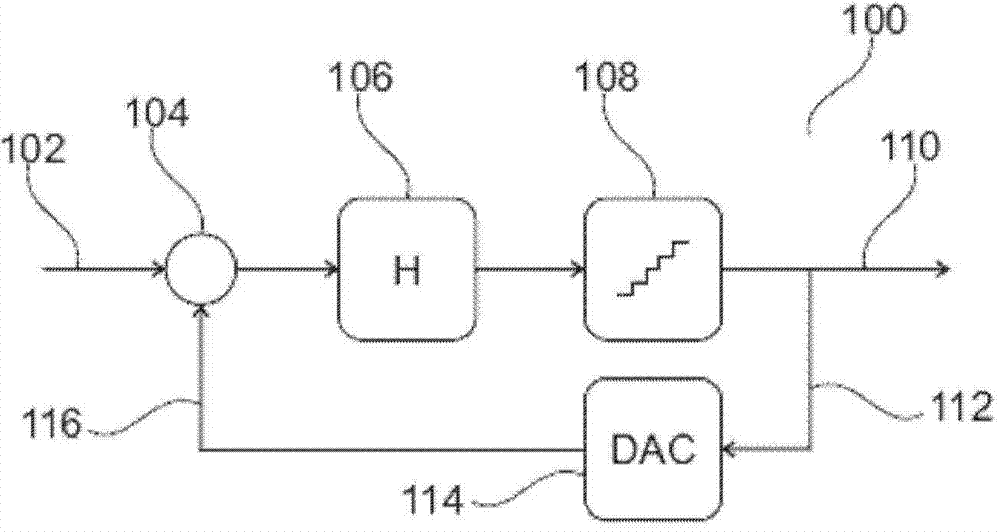

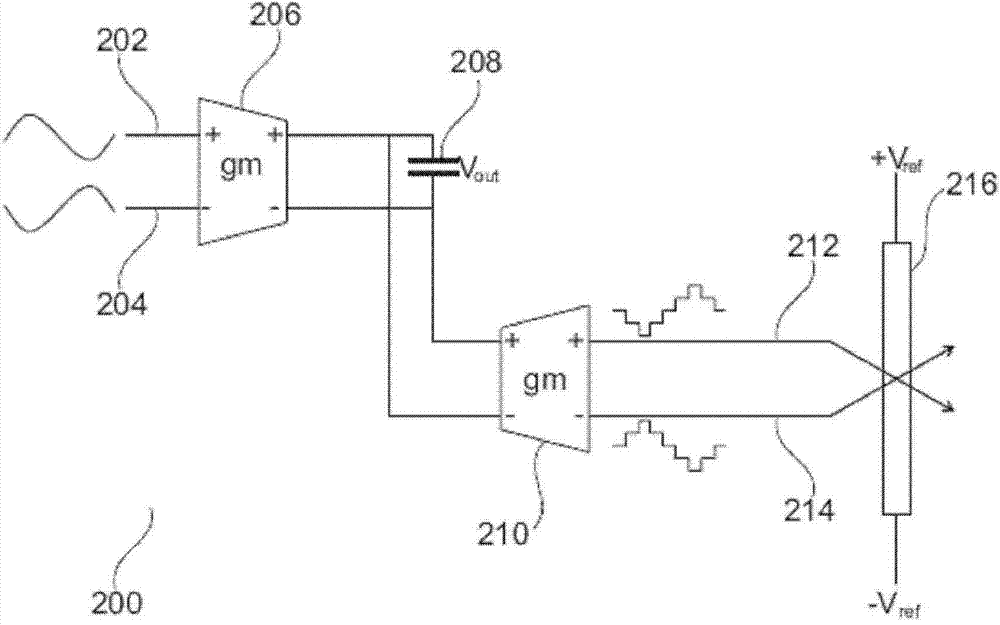

[0048] about figure 1 and figure 2 , as a reference to the corresponding description given above.

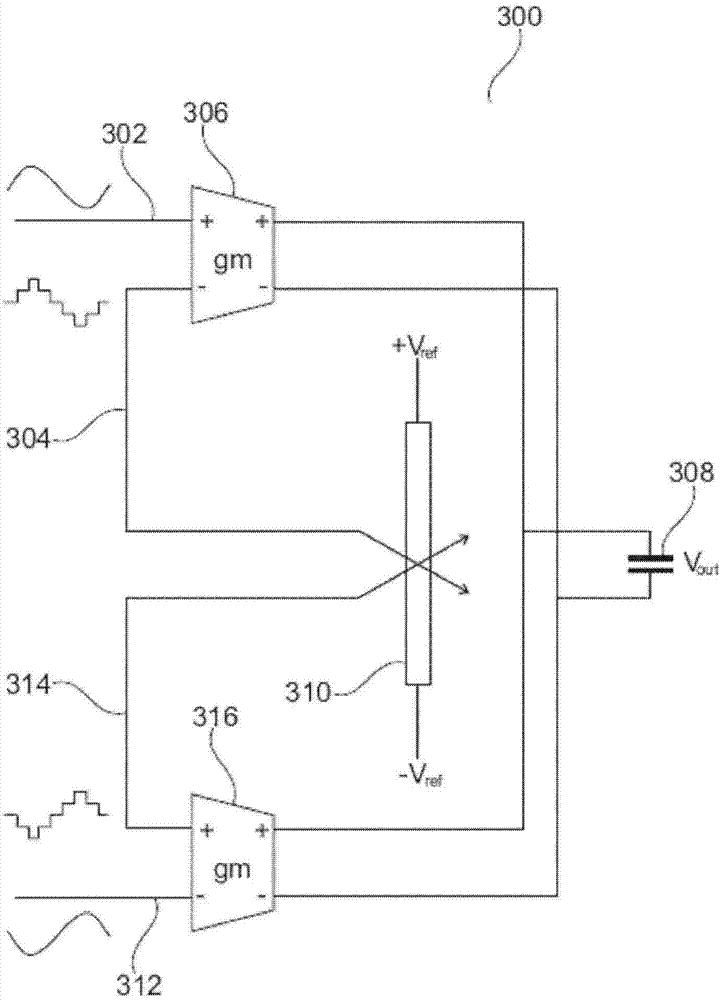

[0049] image 3 A schematic diagram of an input stage for a differential analog-to-digital converter according to an embodiment of the invention is shown.

[0050] Typically, the input stage 300 is structured with figure 2 The input stage 200 of the known art shown differs in that each transconductance element of the input stage 300 receives an analog input signal and an analog feedback signal having the same polarity, so that each transconductance element of the input stage 300 is more than figure 2 The transconductance element of the known art input stage 200 experiences less signal swing.

[0051] More specifically, as image 3 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com