pneumatic tire

A technology for pneumatic tires and bead cores, applied to the reinforcement layer of pneumatic tires, tire parts, bead edges, etc., which can solve the problems of rubber bareness and achieve excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

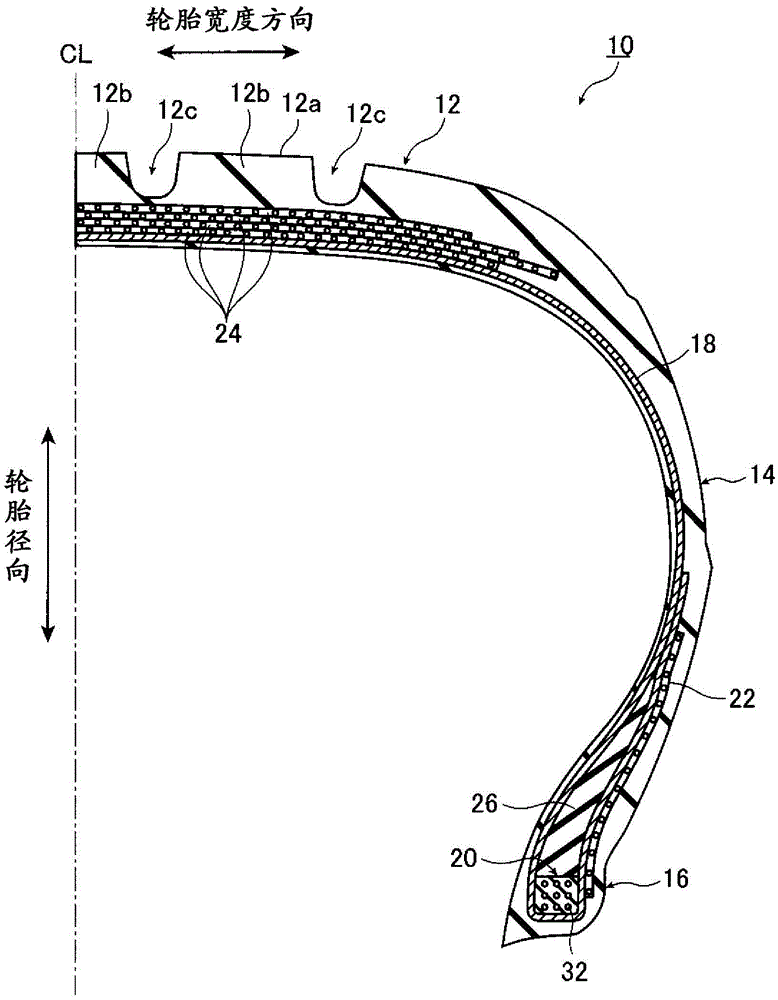

[0075] The pneumatic tire of the present invention will be specifically described.

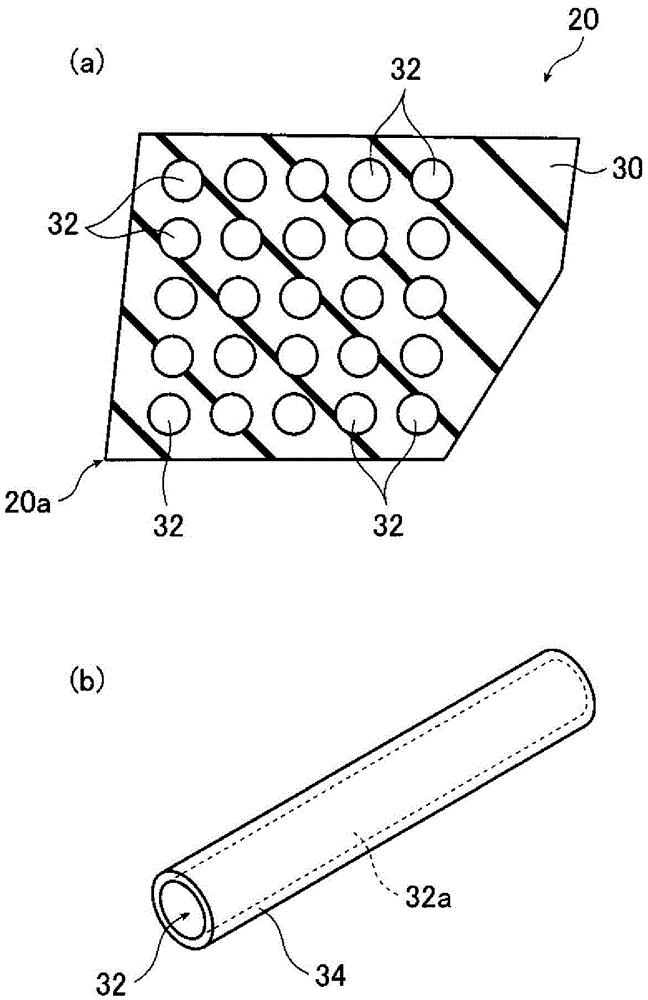

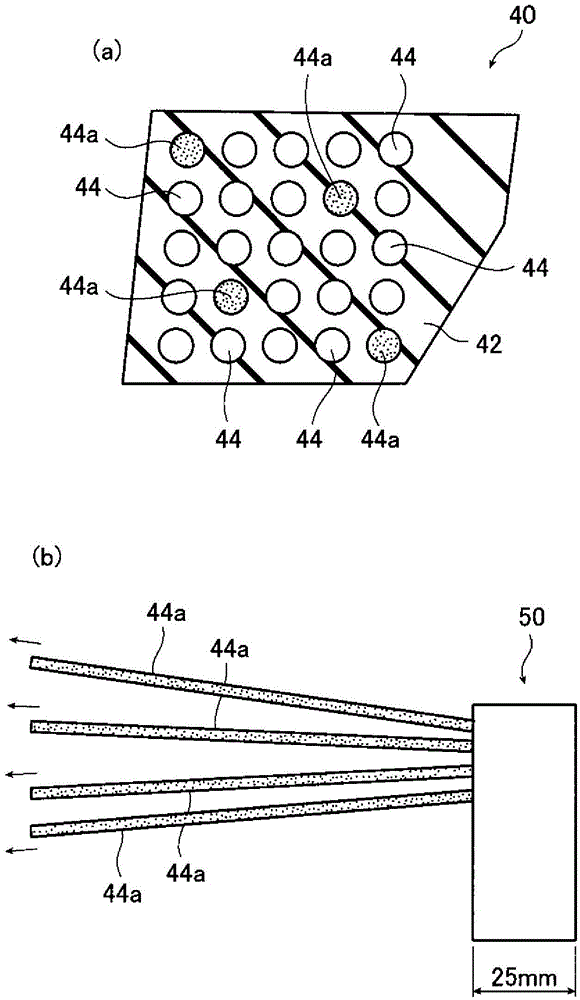

[0076] In this example, the bead wires of Conventional Examples 1 and 2, Examples 1 and 2, and Comparative Examples 1 to 4 having the structures shown in Table 1 below were used to produce image 3 The bead core 40 shown in (a) is then manufactured into a tire. in addition, image 3 The basic structure of the bead core 40 shown in (a) and figure 2 The bead core 20 shown in (a) is the same.

[0077] Regarding each of Conventional Examples 1 and 2, Examples 1 and 2, and Comparative Examples 1 to 4, the work environment, rubber baldness resistance, and tire adhesiveness were evaluated. Table 1 below shows the results of the working environment, rubber baldness resistance, and tire adhesiveness.

[0078] In the bead core 40, the rubber composition 42 mainly contains the following substances. Substances mainly contained in the rubber composition 42 include NR, SBR, CB, calcium carbonate, alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com