Picnic mat and manufacturing method thereof

A production method and technology for picnic mats, applied in chemical instruments and methods, dyeing methods, travel or camping equipment, etc., can solve the problems of high price, poor printing effect, and no waterproofing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

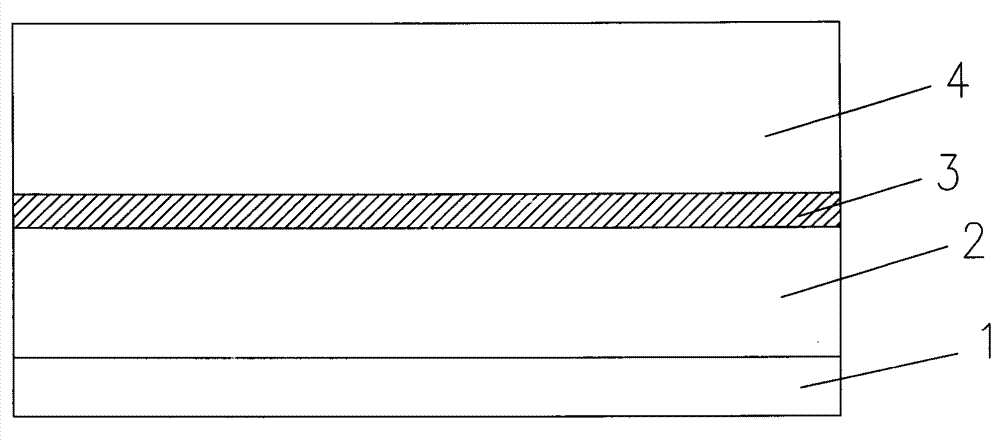

[0021] Such as figure 1 Shown, a kind of picnic mat comprises the waterproof layer 1 positioned at the lower side, the printed polyester 4 positioned at the upper side, and the pearl cotton lining 2 between the waterproof layer 1 and the printed polyester 4, the waterproof layer 1 and the pearl A latex layer 3 is arranged between the cotton linings 2, the thickness of the waterproof layer is 0.15-0.22 mm, the thickness of the pearl cotton lining 2 is 1-1.5 mm, and the thickness of the printed polyester 4 is 0.8-1.2 mm.

[0022] The waterproof layer 1 is a polyethylene layer, a polyvinyl chloride layer or a polypropylene layer, and this embodiment is a polyethylene layer.

[0023] The production process of printed polyester 4 is: print the pattern on the white paper, and print the white paper wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com