Cooling device for generating flat spraying jet

A technology of cooling device and jet flow, which is applied in the direction of metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of slow closing water flow, slow opening water flow of cooling device, poor heat resistance, etc., to achieve fast cut-off response and heat protection Good effect, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

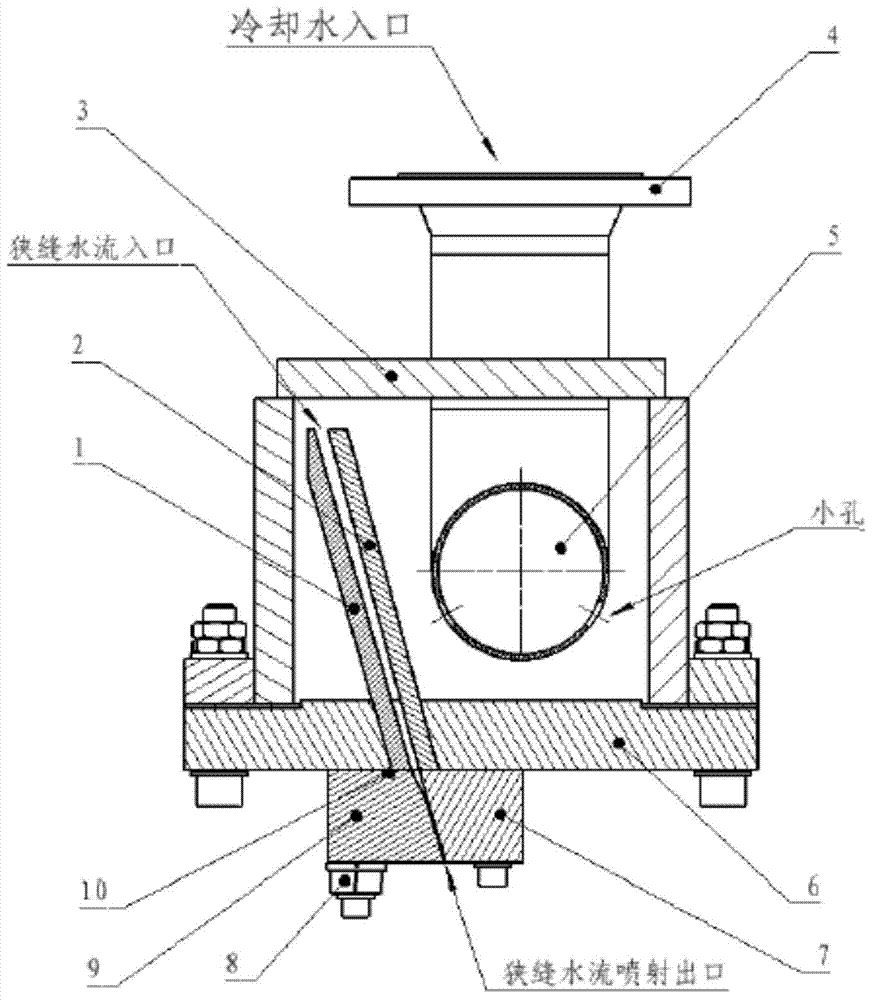

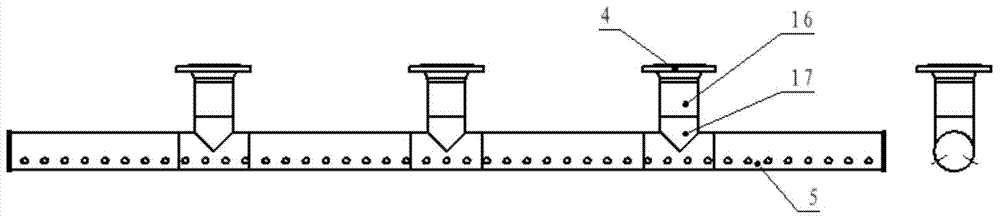

[0046] Such as figure 1 As shown, the cooling device of this embodiment includes: a first drain plate and a second drain plate for forming a drainage channel, a box body, a water inlet pipe assembly, a fixed plate and an adjustable plate for forming a slit, and for adjusting The eccentric bolts with the width of the slit and the temperature-resistant sealing strip used to ensure the watertight sealing of the box.

[0047] In this embodiment, a groove is opened on the lower bottom plate of the box body. The groove is a through groove penetrating the lower bottom plate. The first flow guide plate and the second flow guide plate are embedded on the lower bottom plate of the box body through the groove opened. The lower bottom plate is connected with the side wall of the box by bolts, the first baffle and the second baffle are arranged obliquely, and the drainage channel formed by the first baffle and the second baffle is an inclined gap that gradually narrows from top to bottom. ...

Embodiment 2

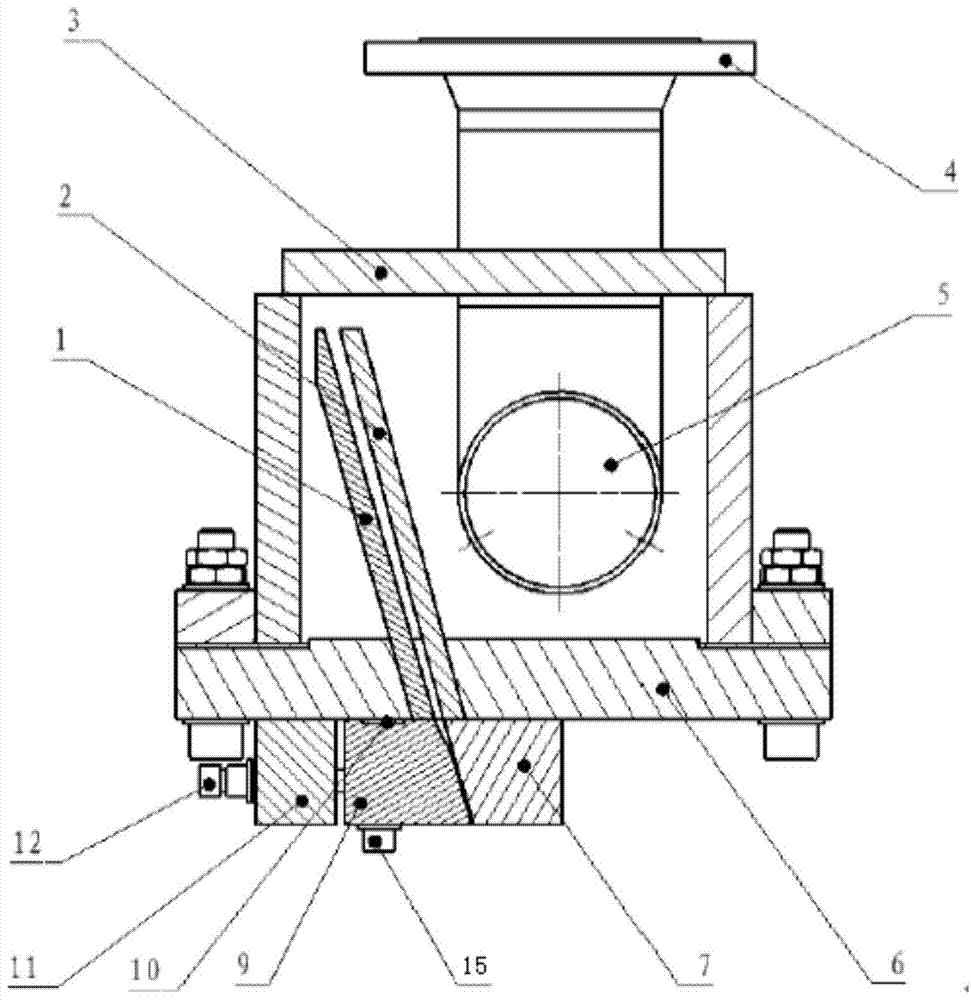

[0056] Such as image 3 The difference between the second embodiment and the first embodiment is that the cooling device of the second embodiment includes a support plate, the support plate is fixedly installed on the lower bottom plate of the box body, and the adjustable plate passes through The first adjusting bolt is installed on the lower bottom plate of the box body, and the support plate is connected with the adjustable plate through the second adjusting bolt.

[0057] This embodiment shows another form of adjustment of the slit width. In this embodiment, the support plate is fixed on the lower bottom plate of the box body, supported by the support plate, and the relative position between the adjustable plate and the fixed plate can be adjusted by tightening or compressing the second adjusting bolt, thereby adjusting Slit width. This embodiment does not need to use eccentric bolts, and the structure is simple and easy to process.

[0058] The present invention adjusts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com