Fixture for horizontal stroke lathe

A technology of horizontal lathes and spokes, applied in the field of horizontal lathes, which can solve problems affecting the accuracy of spoke processing, low thread positioning accuracy, and impact on automobile operation, so as to avoid thread wear, shorten clamping time, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

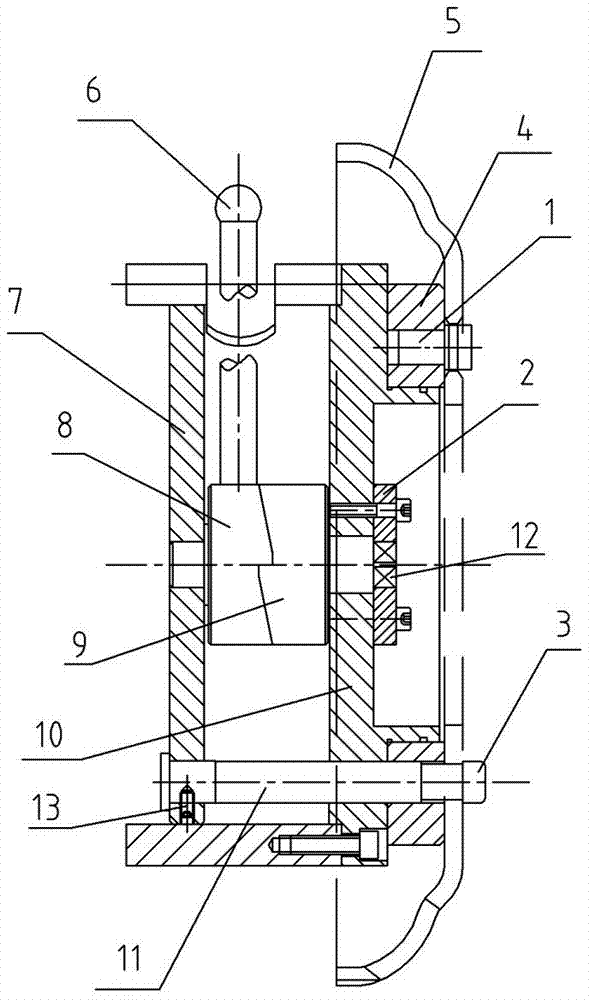

[0014] The present invention will be described in further detail below by way of specific implementation: as figure 1 As shown, this embodiment provides a clamp for a spoke horizontal lathe, including a clamp body, a positioning plate 4, a handle 6, a plane cam, a tensioning structure and two pull rods 11, wherein the clamp body includes a static clamp body 10 and a movable clamp Specifically 7, the planar cam is located between the static clamp body 10 and the movable clamp body 7, the plane cam includes a movable cam 8 and a fixed cam 9, and the fixed cam 9 and the movable cam 8 abut against each other. The lower end of the handle 6 is welded to the movable cam 8; the movable cam 8 is rotationally connected to the movable clamp body 7; the fixed cam 9 is connected to the static clamp body 10 through the cam adjustment piece 3; the cam adjustment piece 3 is arranged on the static clamp body 10 away from the dynamic clamp body 7 On one side, the cam adjusting piece 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com