A flipping and pressing mechanism

A technology of overturning and pressing and rotating shafts, which is applied in the field of pressing mechanisms, can solve the problems of uncontrollable pressing force, inaccurate pressing position, and low work efficiency, and achieve controllable pressing force, increase production efficiency, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

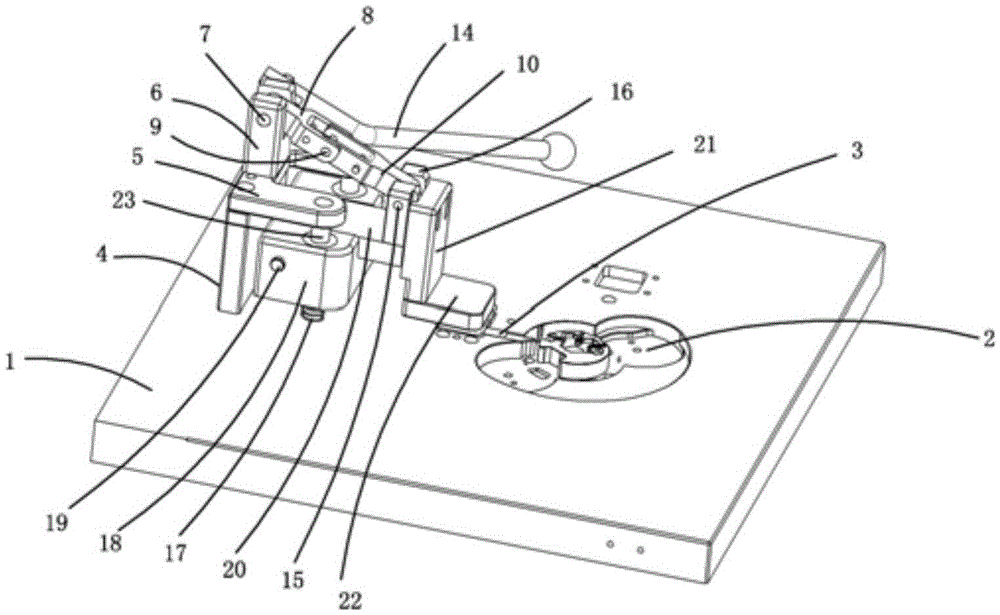

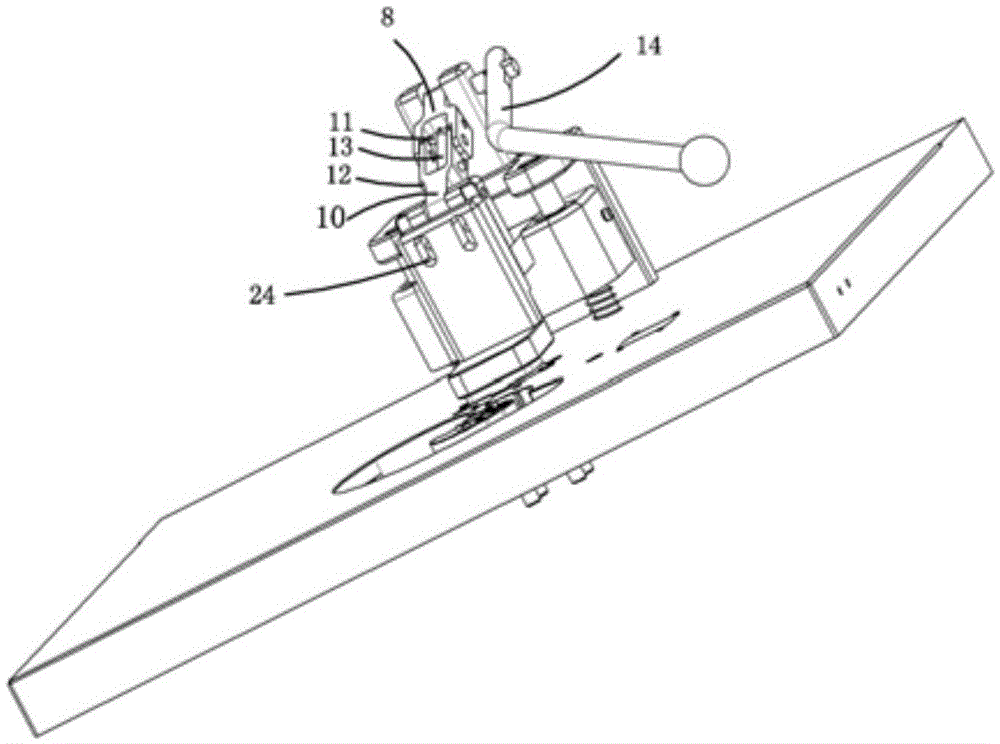

[0016] Examples, see attached figure 1 and 2 , a turning and pressing mechanism, including a panel 1, a groove 2 is arranged on the panel, a product 3 is positioned in the groove, and parts are placed on the product. A support block 4 is installed on the upper left side of the panel, a horizontal fixed block 5 is installed on the support block, a vertical fixed block 6 is installed on the horizontal fixed block, and a Y-shaped connecting rod a8 is connected to the upper part of the vertical fixed block through a rotating shaft a7. The other end of the Y-shaped connecting rod a is connected to the Y-shaped connecting rod b10 through the rotating shaft b9, and the open end of the Y-shaped connecting rod a and the open end of the Y-shaped connecting rod b are installed together through two rotating shafts b.

[0017] A fixed shaft a11 is installed on the Y-shaped connecting rod a, a fixed shaft b12 is installed on the Y-shaped connecting rod b, and the fixed shaft a and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com