Bus handrail system

A bus and handrail technology, applied in vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of crowded bus, hot bus, passenger slippage, etc., and achieve the effect of large frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

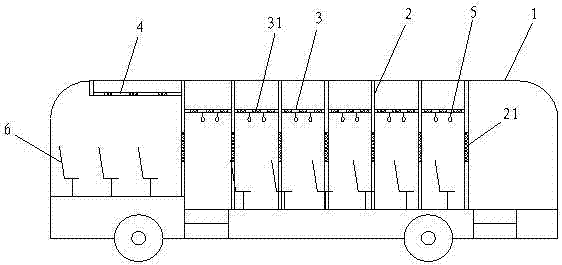

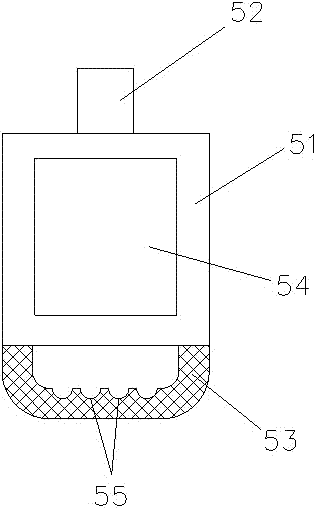

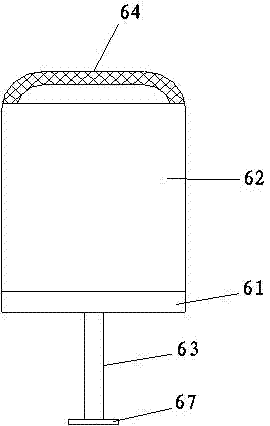

[0018] Embodiment one: if Figure 1~4 As shown, a bus 1 armrest system includes a seat 6, a handrail and a handle 5 arranged in the compartment, and the seat 6 includes a seat plate 61, a backrest 62 and a support column 63 arranged at the bottom of the seat plate, Several through holes 65 are evenly distributed on the seat plate 61 to ensure ventilation and no water accumulation of the seat plate. The top of the backrest 62 is provided with an arc-shaped handle 64, which is a hollow cylinder Shaped body, the side wall of the tubular body is provided with a hollowed-out grid, and the support rod includes several vertical rods 2 arranged at intervals on both sides in the compartment, a horizontal rod 3 connecting two adjacent vertical rods, and a horizontal rod 3 arranged on the The long horizontal bars 4 on both sides of the rear part of the compartment, the vertical bar 2 is provided with a long hollow section 21 at a distance of 0.5m to 1.5m from the ground, and the horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com