Fancy yarn production method

A production method and fancy yarn technology, applied in the field of spinning, can solve problems such as difficult to achieve continuous covering production, limited length of outer covering yarn, and restriction of rotation speed, so as to improve machine motion stability, save winding steps, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

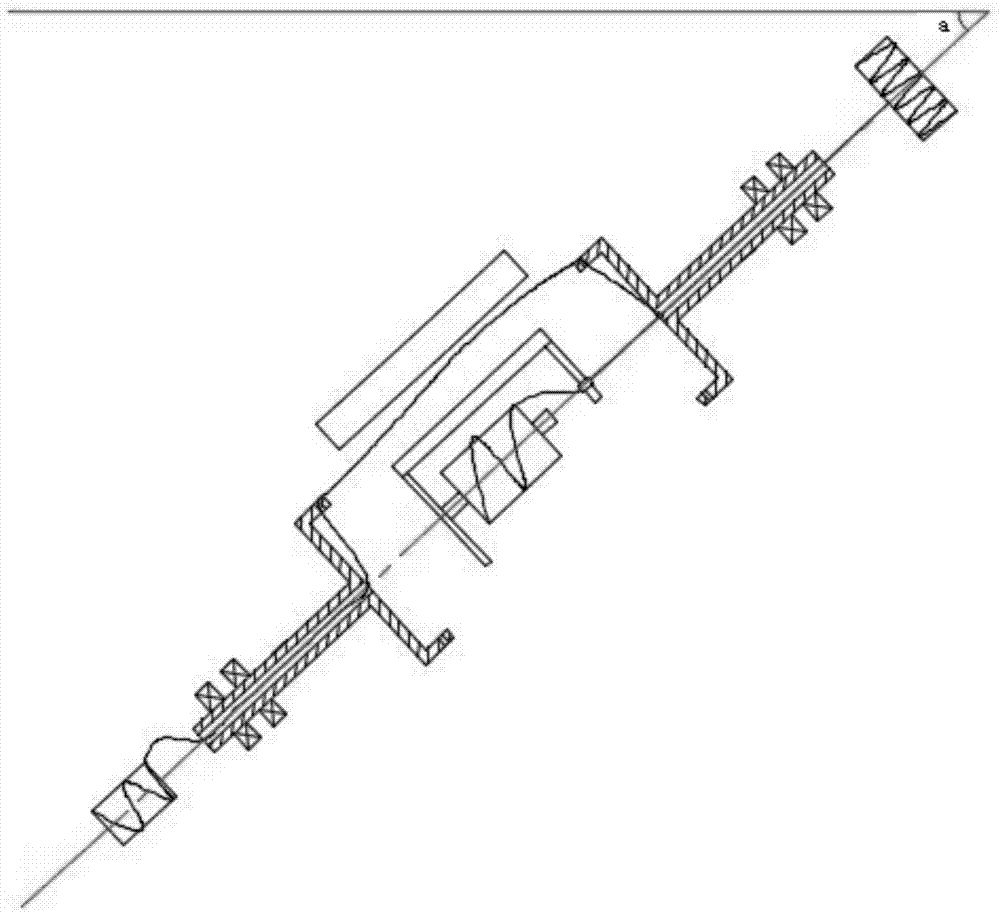

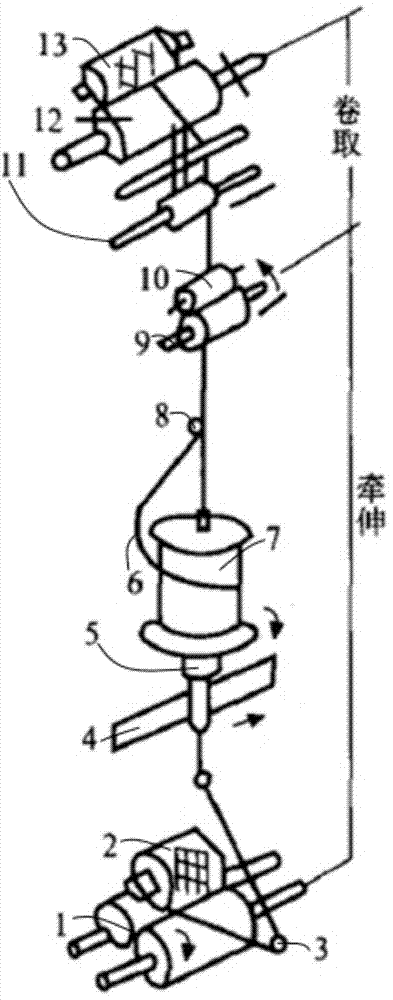

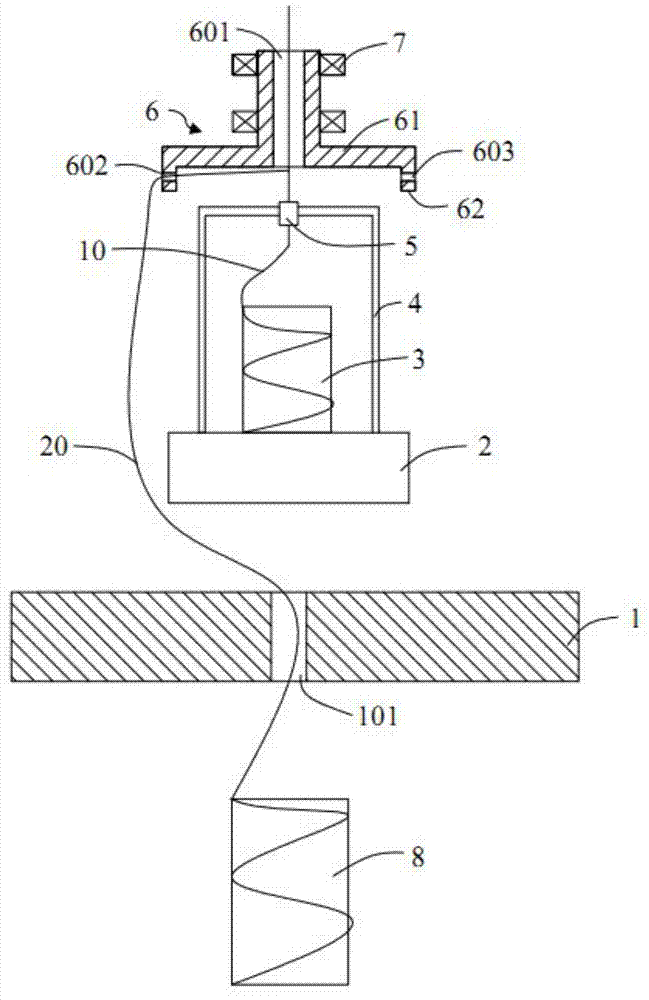

[0035] Embodiment 1: as figure 2 Shown, a kind of fancy yarn device comprises following structure:

[0036] The suspending body 2 is suspended above the suspending support body 1 without being in contact with the suspending support body 1, and its function is to allow the outer covering yarn to rotate freely there without being disturbed. The suspending body 2 and the suspending support body 1 are suspended in the form of electromagnetic levitation, and its internal structure and specific driving principle are consistent with those in the prior art, so they are not shown in the figure. The suspension 2 is used to support the core yarn reel 3 , and the core yarn reel 3 is placed on the suspension 2 during use, so that the core yarn 10 can be pulled out from above the suspension 2 .

[0037] Mounting frame 4, a mounting frame 4 is arranged on the suspension body 2, and a tensioner 5 is installed on the mounting frame 4, so that the core yarn 10 output by the core yarn drum 3 i...

Embodiment 2

[0049] Embodiment 2: As another suspension method, the suspension support body 1 is located above the suspension body 2 to make it in a suspended state, the installation frame 4 is fixed on the bottom of the suspension body 2, and is U-shaped, and the core yarn reel 3 is placed on the installation In the inner space of frame 4.

[0050] If the position of the outer yarn reel 8 is still arranged at the bottom, then as Figure 4 As shown, holes are opened on the suspension body 2 to facilitate the output of the core yarn from the core yarn reel 3, and the outer covering yarn released from the outer covering yarn reel 8 passes through the guide wire hole of the rotating part 6, and the rotation of the rotating part 6 drives it in the rotating part. The core yarn is covered in the space between 6 and the suspension 2, and the fancy yarn is output from the center hole. In order to ensure the suspension effect, a certain distance needs to be kept between the suspension support body...

Embodiment 3

[0053] Embodiment 3: The rotating part 6 can not only be arranged directly above the suspension body 2 and its core yarn reel 3 as shown in Embodiment 1, but also can be arranged directly below the suspension body 2 and its core yarn reel 3 .

[0054] like Figure 7 As shown, the longitudinal section of the main body of the rotating part 6 under the suspension 2 is T-shaped, and the ring-shaped protrusion is fixed on the upper part of the main body to form a whole. The yarn rotates on the outer circumference of the mounting frame 4 through the central hole and the guide wire hole of the rotating part 6, and the output core yarn is wrapped on the mounting frame 4 and then wound into a tube.

[0055] exist Figure 7 On the basis of the situation, the outsourcing yarn reel 8 can be placed on the top of the mounting frame 4, such as Figure 8 As shown, the outer covering yarn passes through the guide hole of the rotating part 6 to cover the core yarn in the space between the sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com