Applicable to slab-beam bridge slab transportation and installation vehicle

A bridge deck and installation vehicle technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of insufficient safety and stability of posts, consume a lot of time and manpower, and increase erection costs, so as to reduce transportation and erection costs , Convenient suspension installation, stable structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

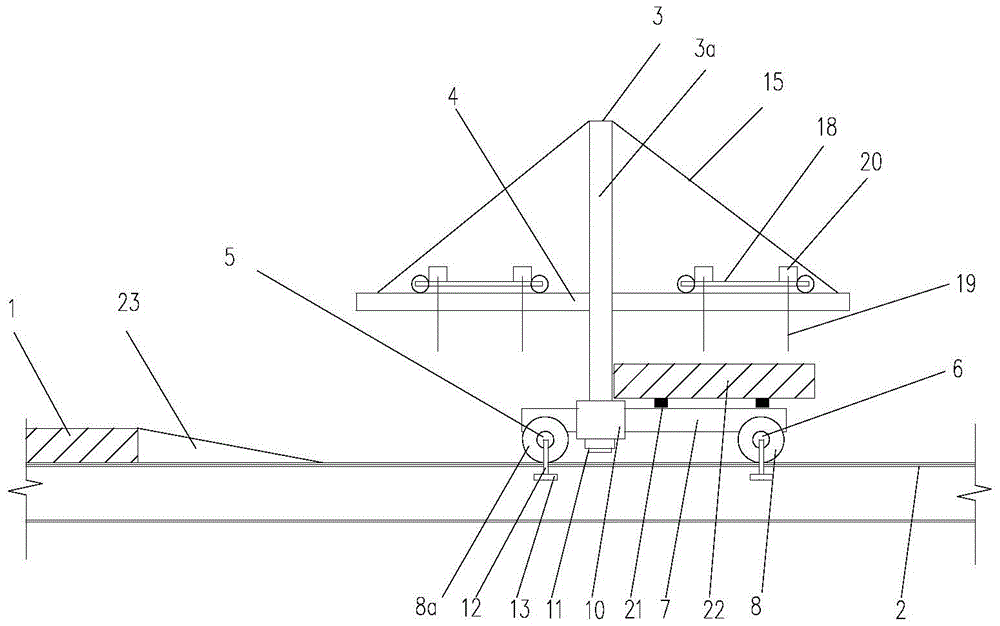

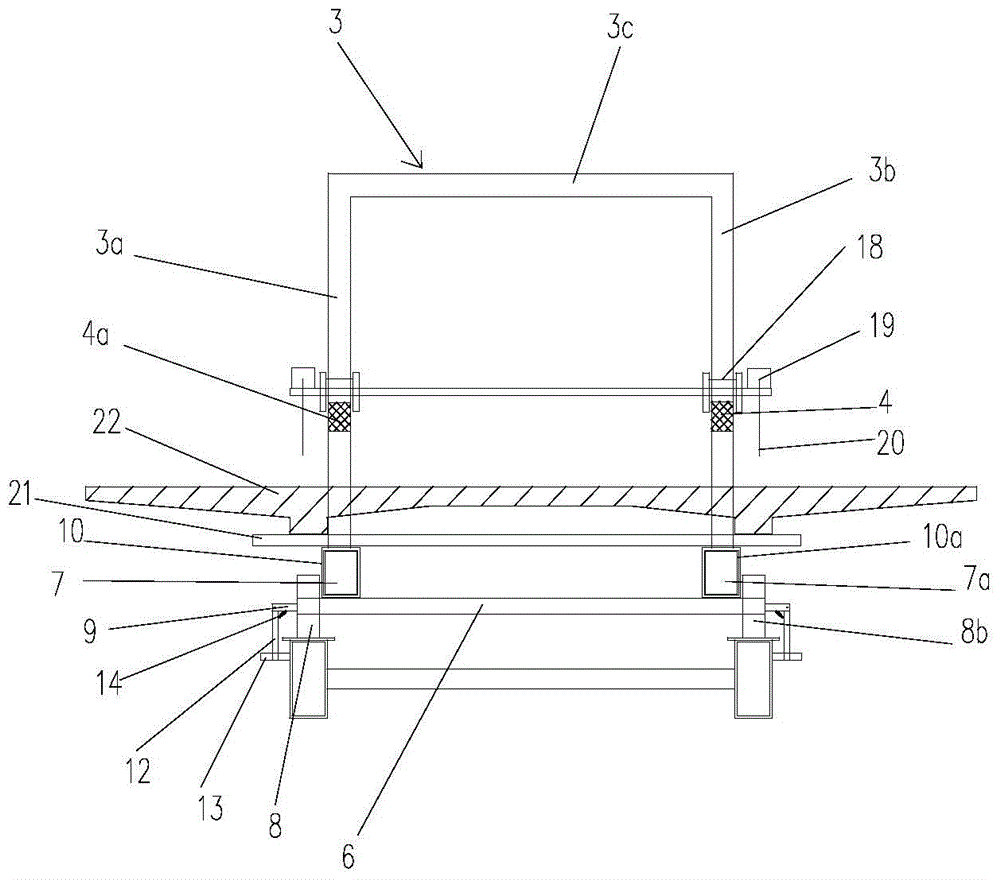

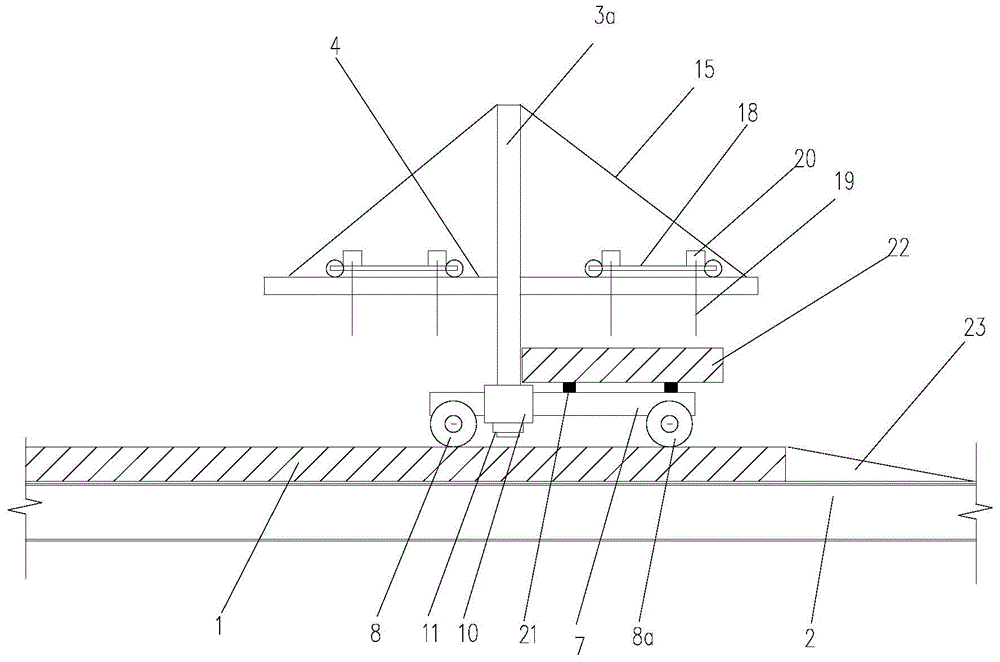

[0026] figure 1 It is a schematic diagram of the state structure when the transport and installation vehicle of the present invention walks on the steel truss beam, figure 2 for figure 1 Schematic diagram of the right side view, image 3 Schematic diagram of the state structure when the transport and installation vehicle walks on the laid bridge slab, Figure 4 for image 3 Schematic diagram of the right side view, Figure 5 It is a schematic diagram of the state structure of the transport and installation vehicle of the present invention when the bridge deck is installed, Image 6 for Figure 5 Schematic cross-sectional view from the right side: the transport and installation vehicle for slab-beam bridge slabs in this embodiment includes an installation component and a walking component that is arranged in cooperation with the installation component and can walk longitudinally along the upper chord of the bridge slab 1 and truss 2 that have been laid;

[0027] The inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com