Motorboat power engine modified by using K14B engine and modification method

A technology of engines and motorboats, applied in the direction of engine lubrication, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

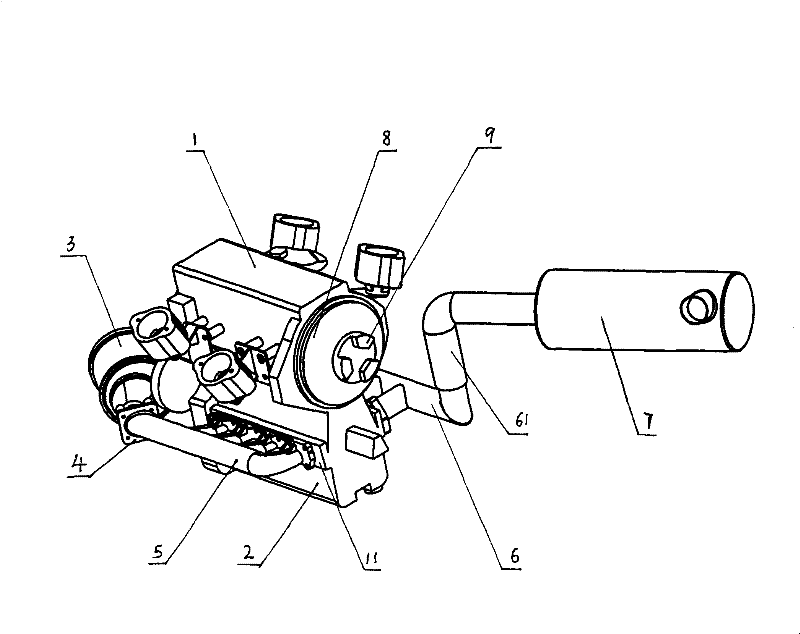

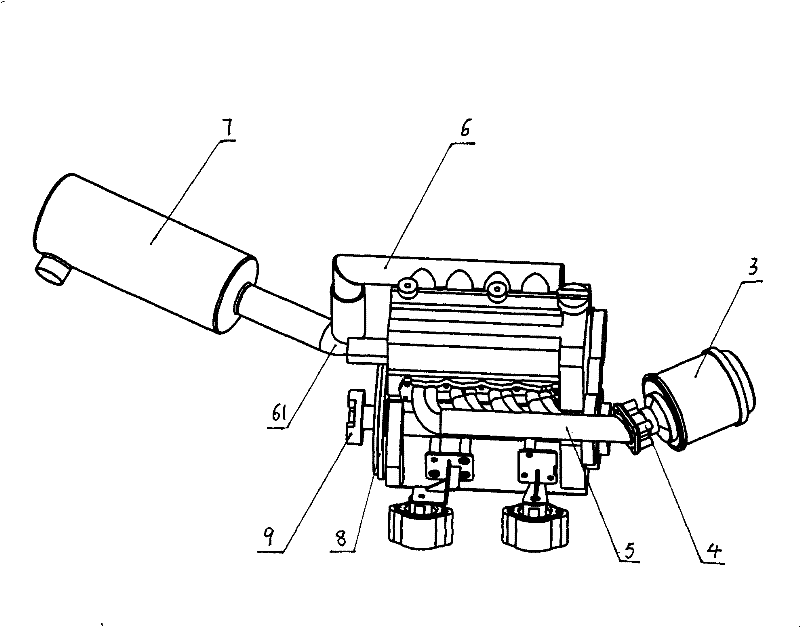

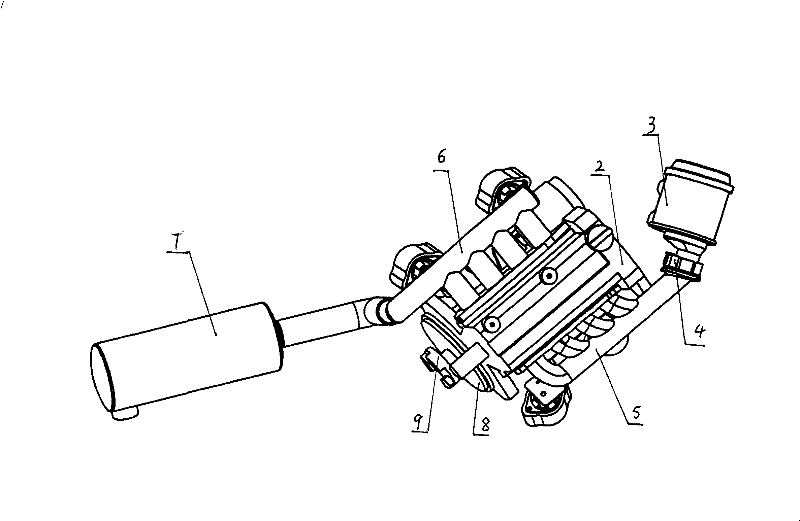

[0062] This embodiment is an improvement to the K14B engine, so that the K14B engine can be adapted to be used on the motorboat as a water power device for the motorboat. Since automobiles and motorboats are two different means of transportation, few people would think of refitting the automobile engine into a motorboat engine. This embodiment and the K14B engine of Changhe Suzuki equally comprise body 1, crank-link mechanism, gas distribution mechanism, lubricating mechanism, fuel supply mechanism, cooling mechanism, starting mechanism, ignition mechanism, muffler; Same with the engine. The K14B engine of present embodiment and Changhe Suzuki has the place of four modifications.

[0063] Please refer to Figure 1 to Figure 4 , The first modification of this embodiment is to reduce the distance from the center of the K14B engine shaft to the bottom of the oil pan 2 and change the installation direction of the oil filter 3 . Because the distance from the shaft center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com