Nonmetal blade of venetian blind and manufacturing method thereof

A non-metallic and curtain technology, applied in windows/doors, door/window protection devices, shading screens, etc., can solve the problems of poor lateral bending resistance, poor portability, and high production cost, and achieve firm butt joints and easy use The effect of light weight and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

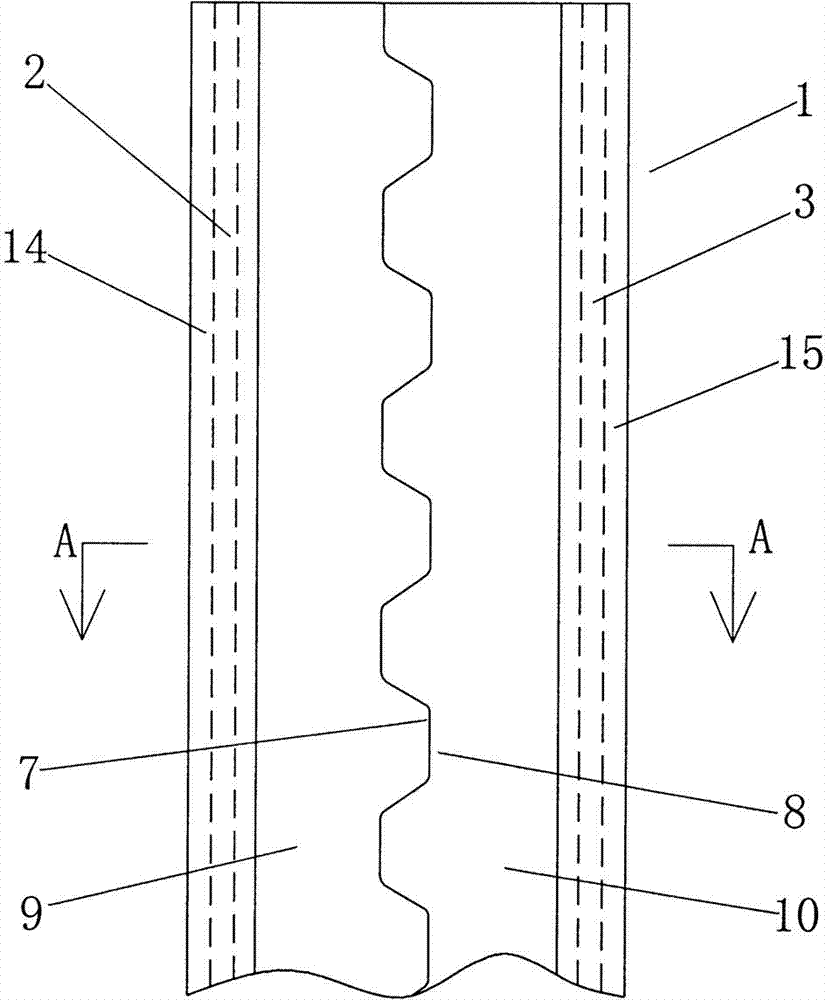

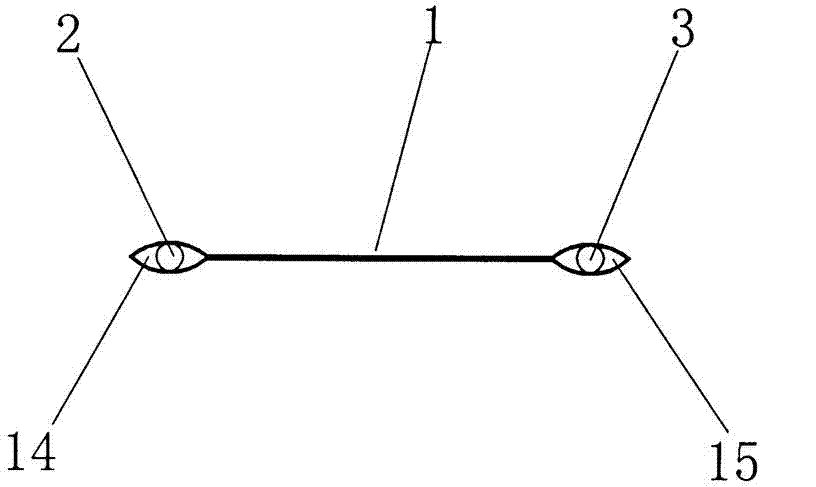

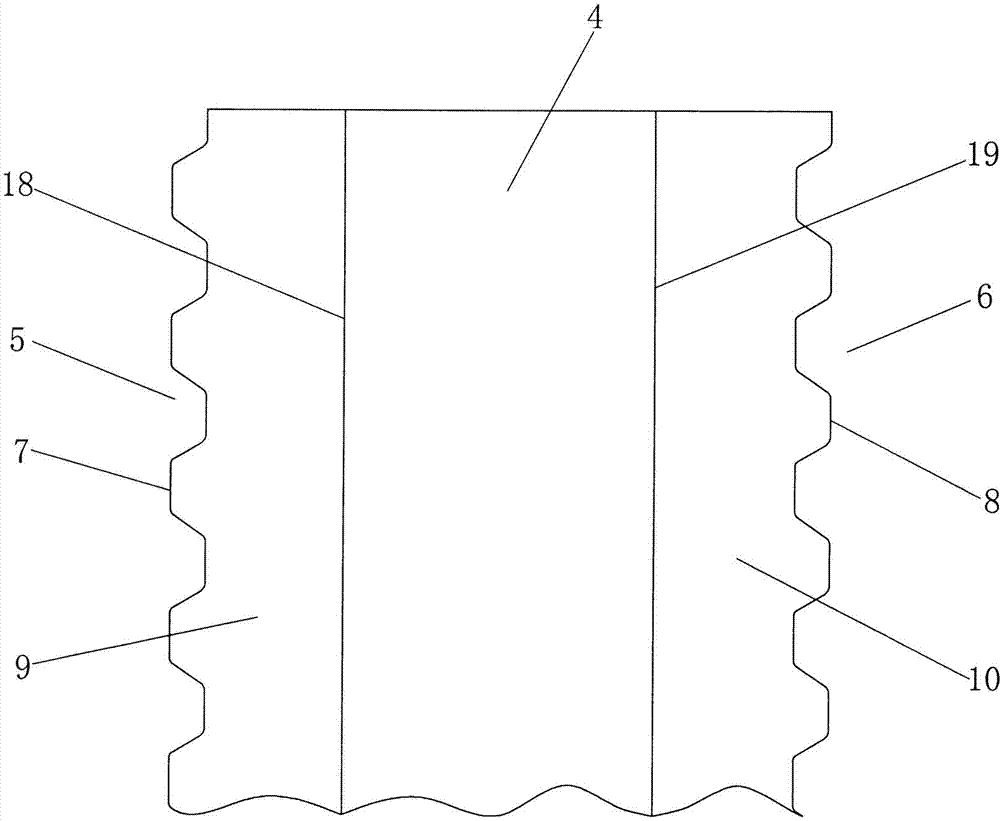

[0046] Reference Figure 1 ~ Figure 5 , The non-metallic blade of the blind is a non-metallic sheet strip 1, in which rods 2, 3 are inserted, and it is characterized in that: the sheet strip 1 is made of a non-metallic strip sheet 4 The two sides 5, 6 of the strip-shaped sheet 4 in the longitudinal direction are respectively processed with corresponding tooth rows 7, 8, and the sides 9, 10 of the strip-shaped sheet 4 in the length direction are both Bend and fold the rubberized surface of the strip-shaped sheet 4, and the tooth rows 7, 8 of the side edges 5 and 6 on both sides are meshed with each other correspondingly. 6 are glued tightly on the adhesive-coated area 11 of the tape-shaped sheet 4 on the adhesive surface, and the strip-shaped areas 12 and 13 on the tape-shaped sheet 4 that are not coated with adhesive are formed with holes in the length direction. 14, 15, the rods 2 and 3 are inserted into the holes 14, 15 respectively.

[0047] In addition, there are two rods 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com