Deep sea multiphase multistage separation and reinjection system

A multi-stage separation and deep-sea technology, which is applied in the fields of mining fluids, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of unguaranteed efficiency and short research time, so as to save processing cost and maintenance cost, and have a large processing range , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

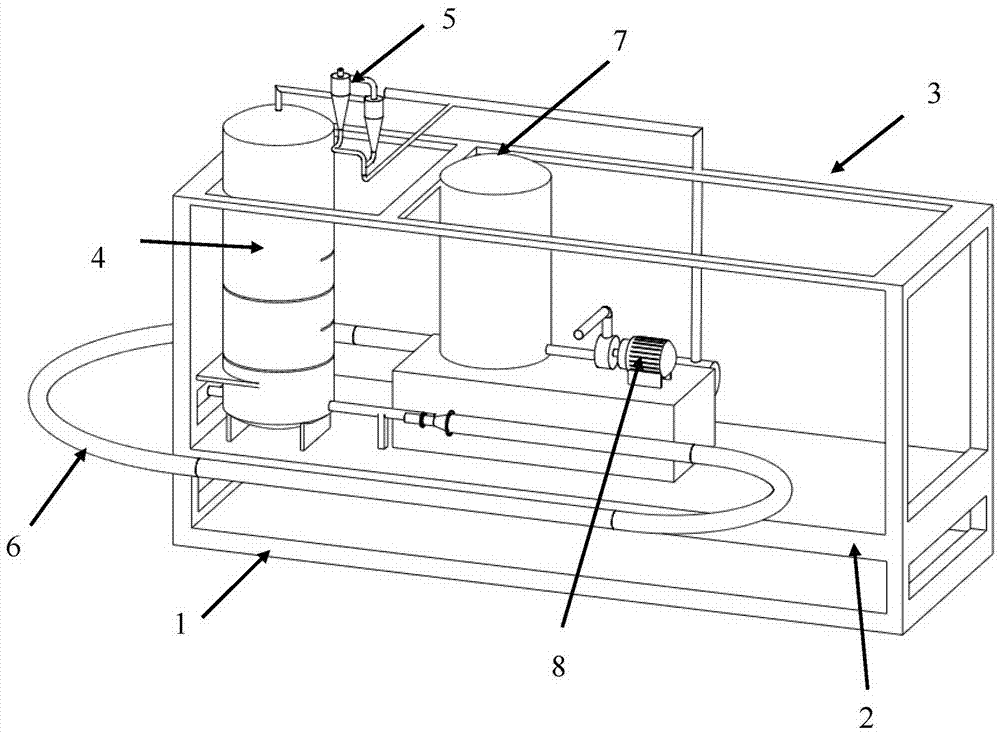

[0019] Such as figure 1 As shown, the deep-sea multi-phase multi-stage separation and reinjection system includes: lower support 1, base platform 2, upper support 3, vertical separator 4, gas-liquid cyclone separator 5, coil type liquid-liquid separator 6. Buffer tank 7 and booster refill pump 8.

[0020] The lower bracket 1, the upper bracket 3, and the base platform 2 are all rectangular flat structures. The lower bracket 1, the upper bracket 3, and the base platform 2 are arranged parallel to each other. The upper bracket 3 is located on the base platform 2, and the lower bracket 1 is located on the base platform 2. Next, the four corners of the lower bracket 1, the upper bracket 3, and the base platform 2 are connected with four bracket legs to form an overall bracket structure. The base platform 2 is provided with a boss, and the boss has a certain height for installing the reinjection system pipeline and valve.

[0021] The lower bracket 1 is used to raise the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com