Novel helicopter water-cooled engine cooling system

A water-cooled engine and heat dissipation system technology, which is applied in the aviation field, can solve the problems of power consumption of helicopters, space occupied by the heat dissipation system, and low heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

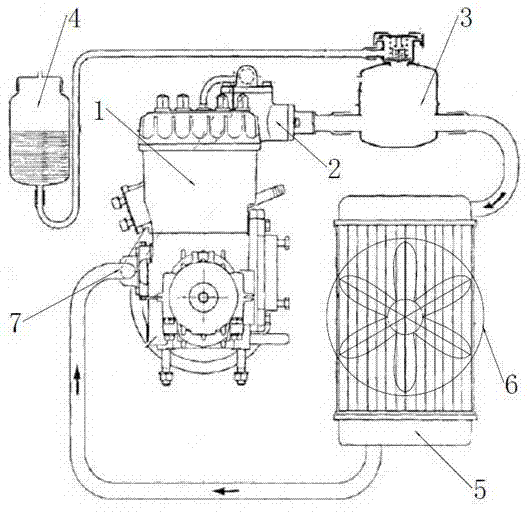

[0024] In order to overcome the shortcomings of the above-mentioned prior art, the present invention provides a novel helicopter water-cooled engine heat dissipation system to solve the problem that the conventional helicopter water-cooled heat dissipation system needs to use an electronic fan to dissipate heat, the system is complicated, and at the same time, it needs to consume precious electric energy on the helicopter to dissipate heat. The efficiency is low, and the heat dissipation system takes up valuable body space and other disadvantages.

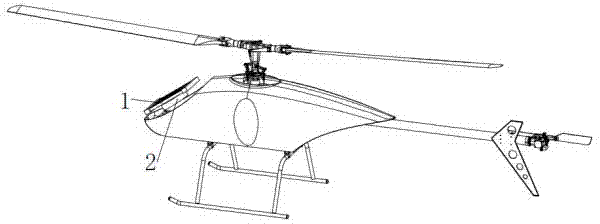

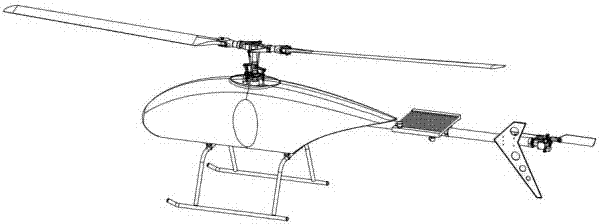

[0025] see Figure 6 , the overall layout of the helicopter water-cooled engine cooling system related to this embodiment is as follows:

[0026] The main rotor system 1 is located at the top of the system, and its downwash flow provides a cooling source for the new helicopter water-cooled engine cooling system.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com