Efficient hybrid engine cooling system and engine cooling method

An engine cooling and high-efficiency technology, applied in the direction of engine cooling, engine components, engine lubrication, etc., can solve the problems of poor turbocharged cooling effect, large electronic water pump workload, and small cooling demand, etc. Little change in layout, maintenance of reliability, effect of short circulation loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

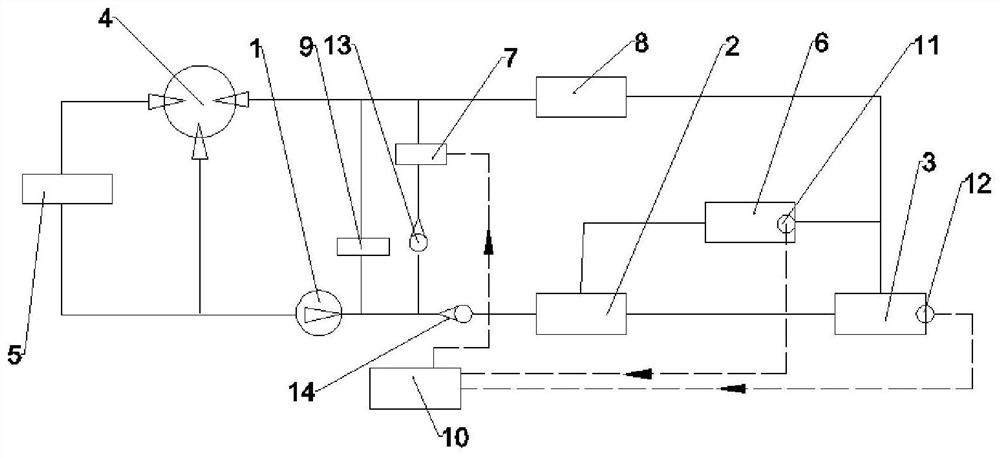

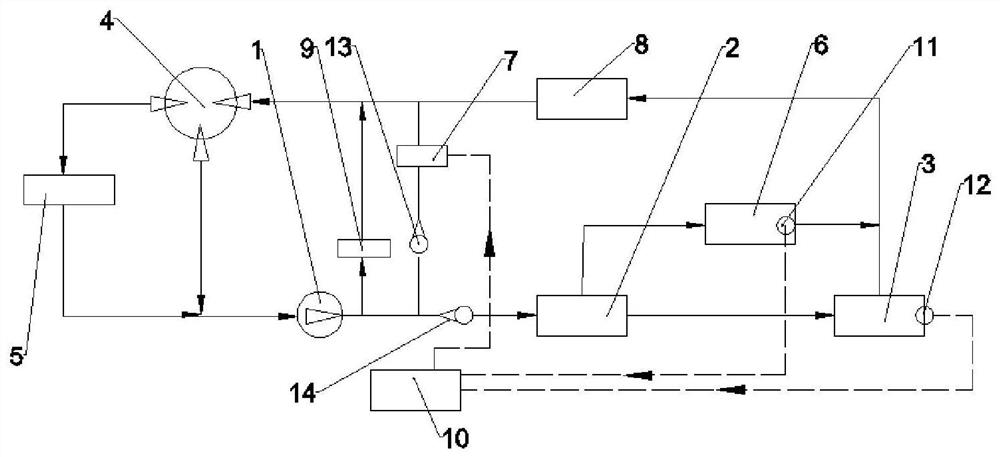

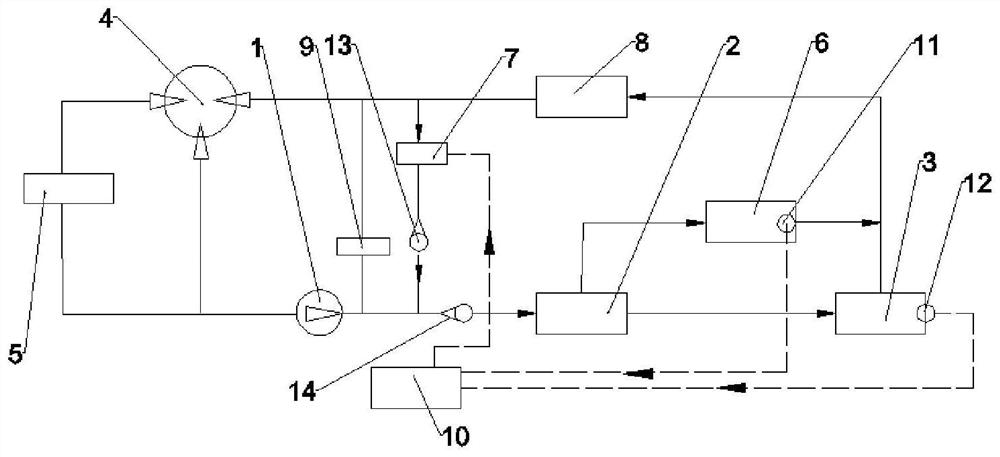

[0041] Such as figure 1 Shown: a high-efficiency hybrid engine cooling system, including the main mechanical water pump 1, the cylinder head water jacket 2, the cylinder water jacket 3, the EGR cooler 8, the thermostat 4 and the radiator 5, which are sequentially connected from end to end to form a water cycle, It also includes an oil cooler 9 whose two ends are respectively connected to the water outlet of the main mechanical water pump 1 and the water outlet of the EGR cooler 8, and whose two ends are respectively connected to the cylinder head water jacket 2 and the water inlet of the EGR cooler 8. The supercharger water jacket 6 is characterized in that: a second one-way valve 13 and an electronic water pump 7 are sequentially arranged in series between the water inlet end of the cylinder head water jacket 2 and the water outlet end of the EGR cooler 8, so that The main waterway between the oil cooler 9 and the second one-way valve 13 is provided with a first one-way valve...

Embodiment 2

[0045] Such as figure 1 As shown, a high-efficiency hybrid engine cooling system includes a main mechanical water pump 1, a cylinder head water jacket 2, a cylinder block water jacket 3, an EGR cooler 8, a thermostat 4 and a radiator 5, which are sequentially connected from end to end to form a water cycle. The present invention adopts a top-down cooling method, that is, cooling water flows from the water jacket 2 of the cylinder head to the water jacket 3 of the cylinder body, and the cooling liquid first flows through the cylinder head and then to the machine body, so that the cooling effect is good.

[0046] This embodiment also includes an oil cooler 9 whose two ends are respectively connected to the water outlet of the main mechanical water pump 1 and the water outlet of the EGR cooler 8, and the two ends are respectively connected to the cylinder head water jacket 2 and the EGR cooler 8. The supercharger water jacket 6 at the water inlet, the EGR cooler 8 is connected in...

Embodiment 3

[0053] This embodiment is an engine cooling method, which adopts a high-efficiency hybrid engine cooling system in the above-mentioned embodiment 2, including the following steps:

[0054] S1. The rotational speed sensor 12 detects the rotational speed of the engine, and the ECU 10 judges the working state of the engine; when the engine is in the running state, the main mechanical water pump 1 is controlled to work; when the engine changes from the running state to the stopped running state, enter step S2;

[0055] S2. Set the water temperature threshold T1>T2>T3, the water temperature sensor 11 detects the water temperature at a time interval Δt, if the current water temperature T is greater than T1 and the water temperature T rises, enter step S201; if the current water temperature T is greater than T1 and the water temperature T decreases , enter step S202; if the current water temperature T is less than T1 and the water temperature T rises, enter step S203; if the current w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com