Improved High Energy Ignition Spark Igniter

A spark igniter and spark technology, applied in the field of ignition systems, can solve problems such as difficulty in forming sparks and reduced output energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] The following examples are provided to illustrate the invention. This example is not intended and should not limit, modify or limit the scope of the present invention in any way.

[0059] Two different ignition activators and five different igniter tip geometries were tested (see Tables 1 and 2 for details of the tests).

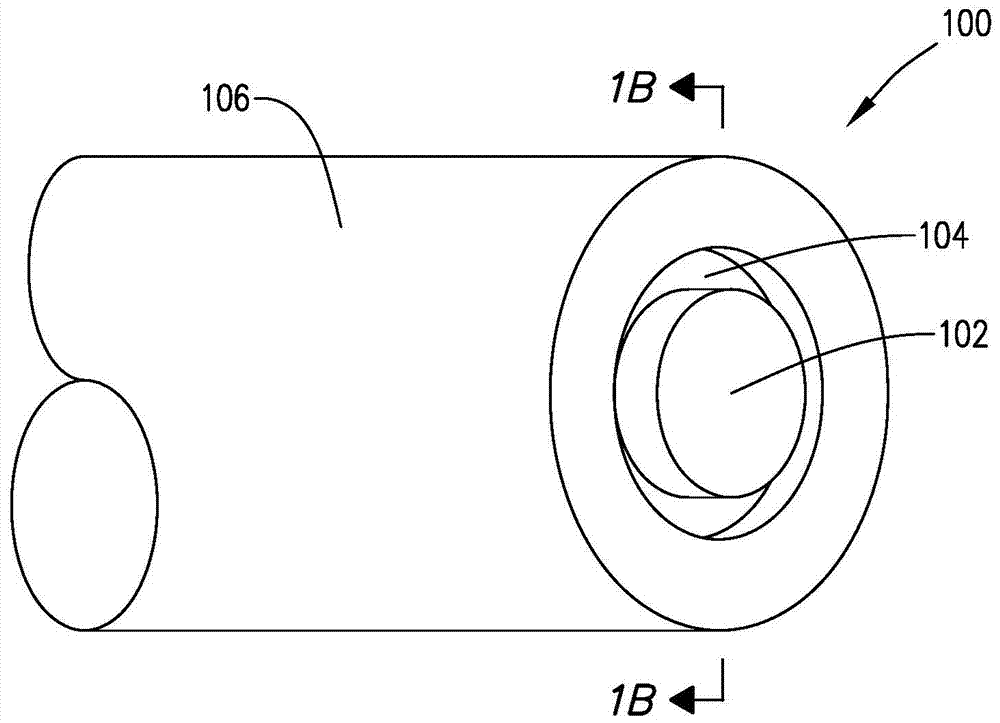

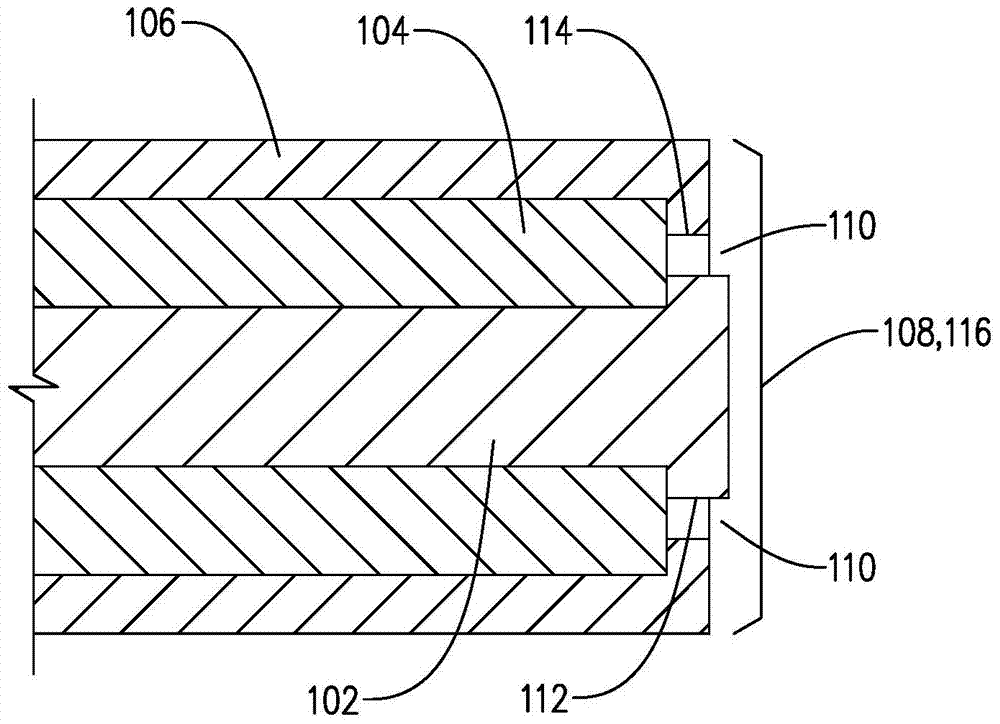

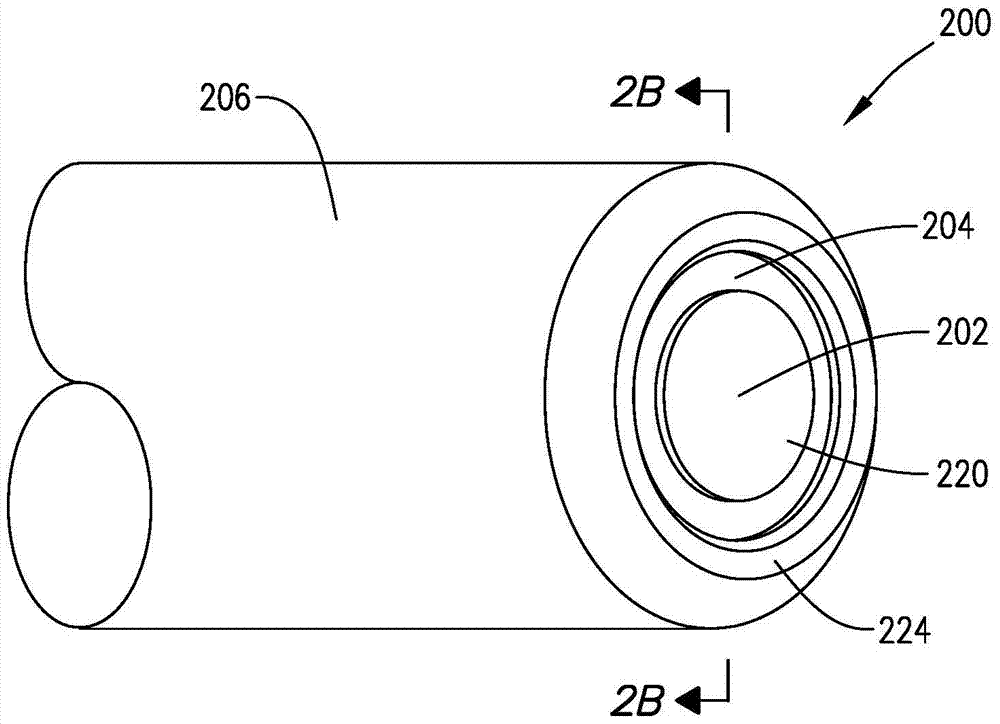

[0060] During the first test, a low energy HEI system (-0.33J) capable of fitting an igniter of approximately 1 / 4 inch diameter was used. Stated another way, the igniter OD, as defined by the outer diameter (OD) of the housing electrode, is 1 / 4 inch in diameter. During this project, three side-firing igniter geometries or radially directed spark igniters were tested. (Refer to Table 1 for specific parameters regarding the geometry.) Table 1 reflects the results of experiments performed with the side-firing design. The results show that by reducing the groove depth and having beveled electrodes and insulators, the electric field concentration betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com