Structure and manufacturing method of mask type read-only memory

A read-only memory and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of poor device uniformity, high process cost, large injection energy, etc., to ensure process uniformity, The effect of stable difference value and lower manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

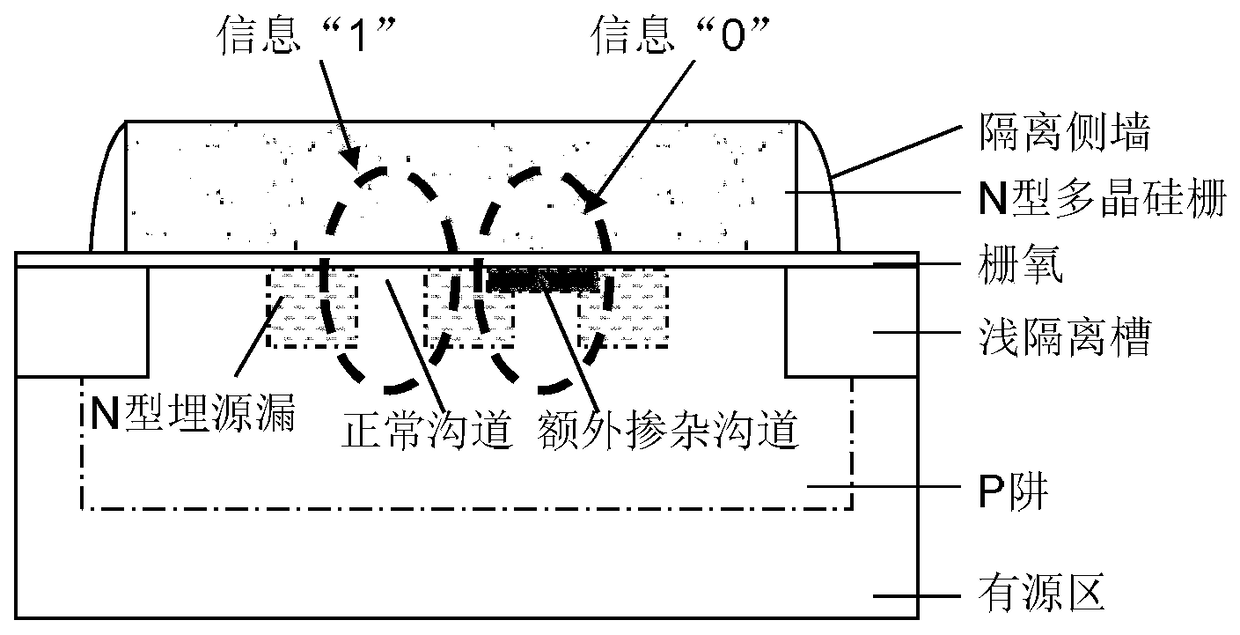

[0021] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the accompanying drawings, the details are as follows:

[0022] The manufacturing method of mask type read-only memory of the present invention, its concrete processing steps are as follows:

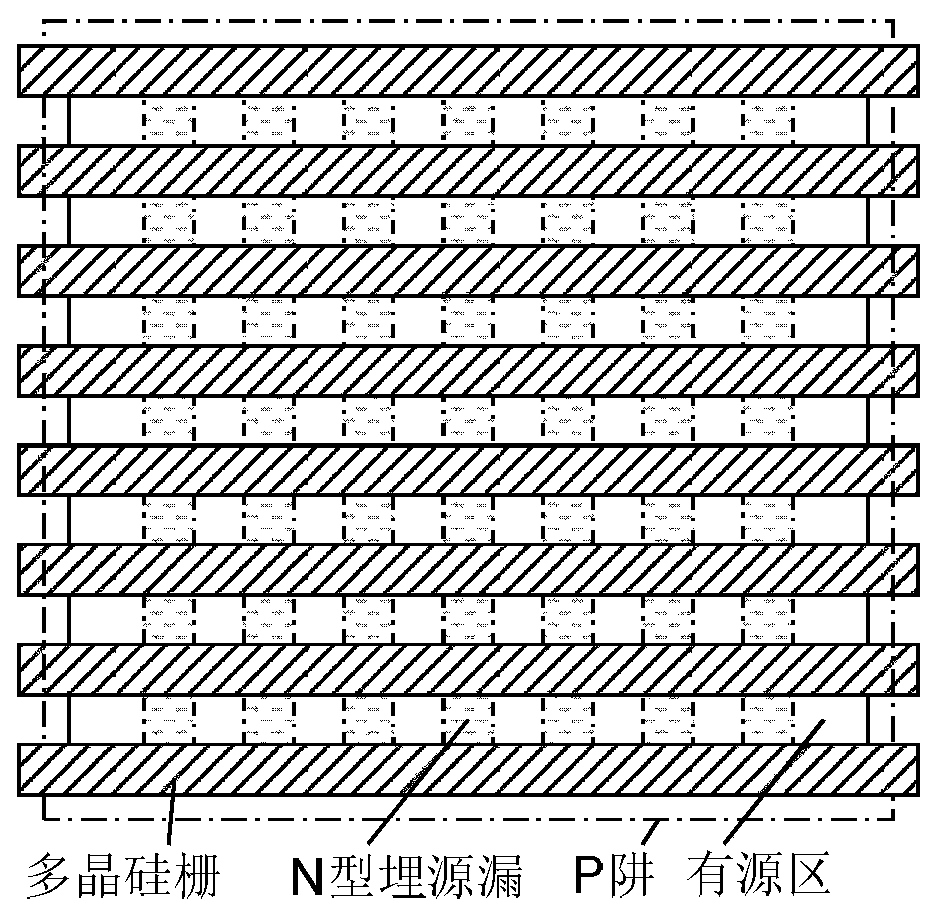

[0023] Step 1, forming shallow isolation trenches on the active area of the silicon substrate to isolate the mask-type read-only memory area from peripheral circuits, such as image 3 shown.

[0024] Step 2, perform P well implantation in the active area of the mask type ROM to form the active area in the P well, such as Figure 4 (Figure B is the top view after this step is completed).

[0025] Step 3, coating N-type buried source and drain photoresist, exposing, and then performing a high-dose arsenic ion or phosphorus ion implantation with low energy to form N-type buried source and drain, such as Figure 5 shown.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com