Reaction chamber and semiconductor processing equipment

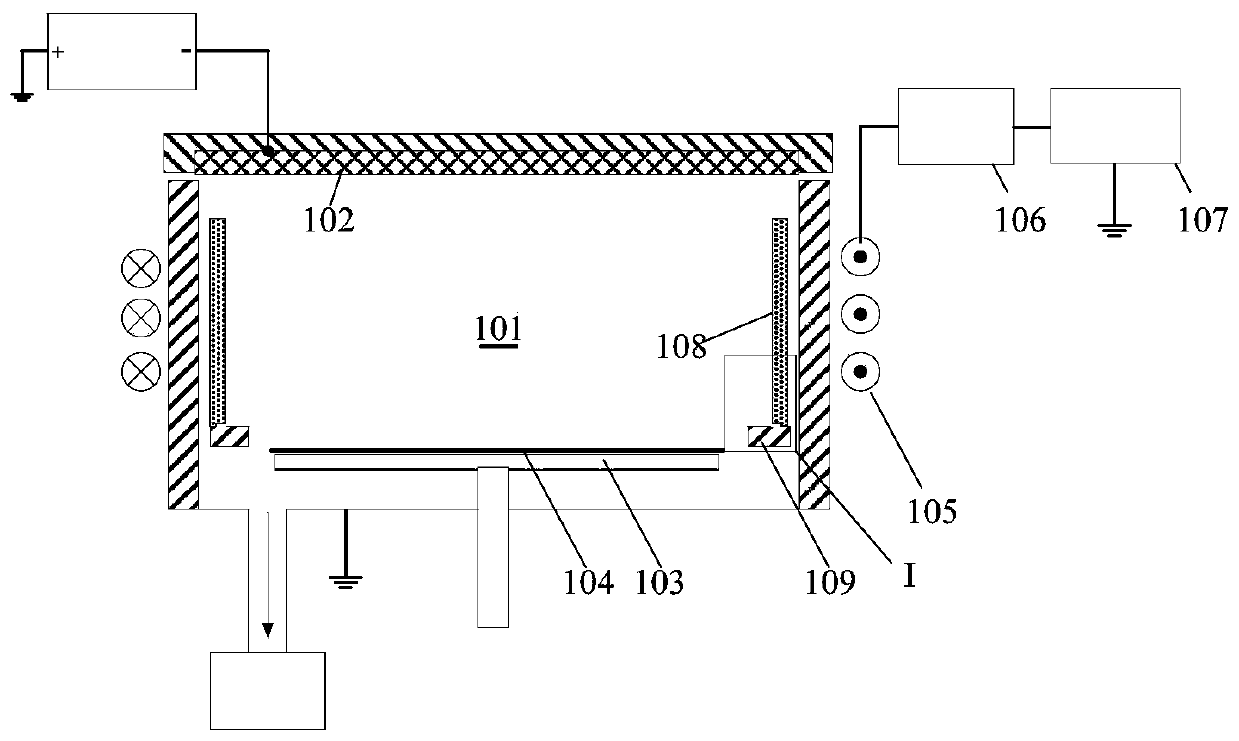

A reaction chamber and chamber wall technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of non-axial sidewalls, exceeding component variation, and breaking of ceramic rings 109, etc. Achieve the effect of improving process stability and equipment reliability, improving process uniformity, and ensuring process uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

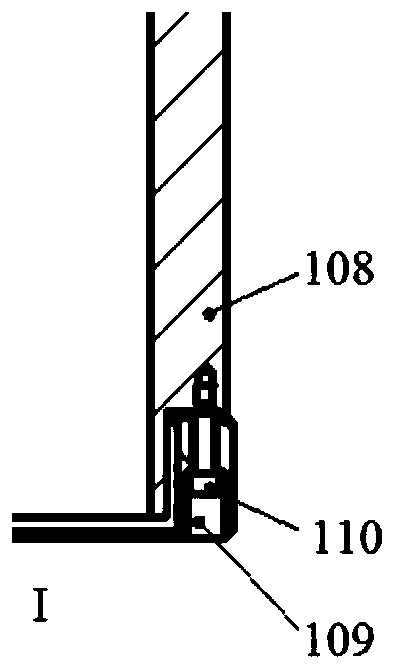

[0034] In order for those skilled in the art to better understand the technical solution of the present invention, the reaction chamber and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

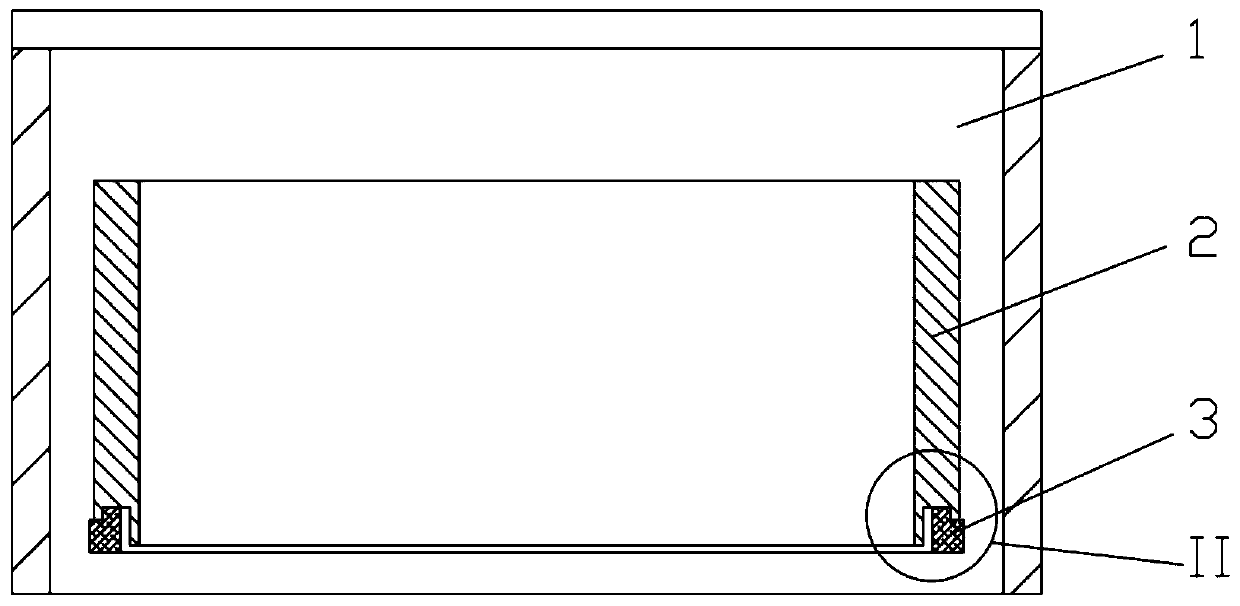

[0035] image 3 A cross-sectional view of a reaction chamber provided for an embodiment of the present invention. see image 3 , the reaction chamber 1 includes a Faraday shielding ring 2 and an insulating ring 3 . Among them, when the reaction chamber 1 is used in the metal deposition process, it is easy to form a metal shield on the inner wall of the chamber using an insulating medium, causing electromagnetic energy to be shielded outside the chamber. For this reason, through the reaction chamber 1 A Faraday shielding ring 2 is arranged around the inner side of the side wall to ensure that radio frequency energy is smoothly coupled into the reaction chamber 1 through the radio frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com