Color conversion layer, organic electroluminescent display panel, and liquid crystal display panel

A color conversion and display panel technology, applied in circuits, optics, electrical components, etc., can solve problems such as poor color saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

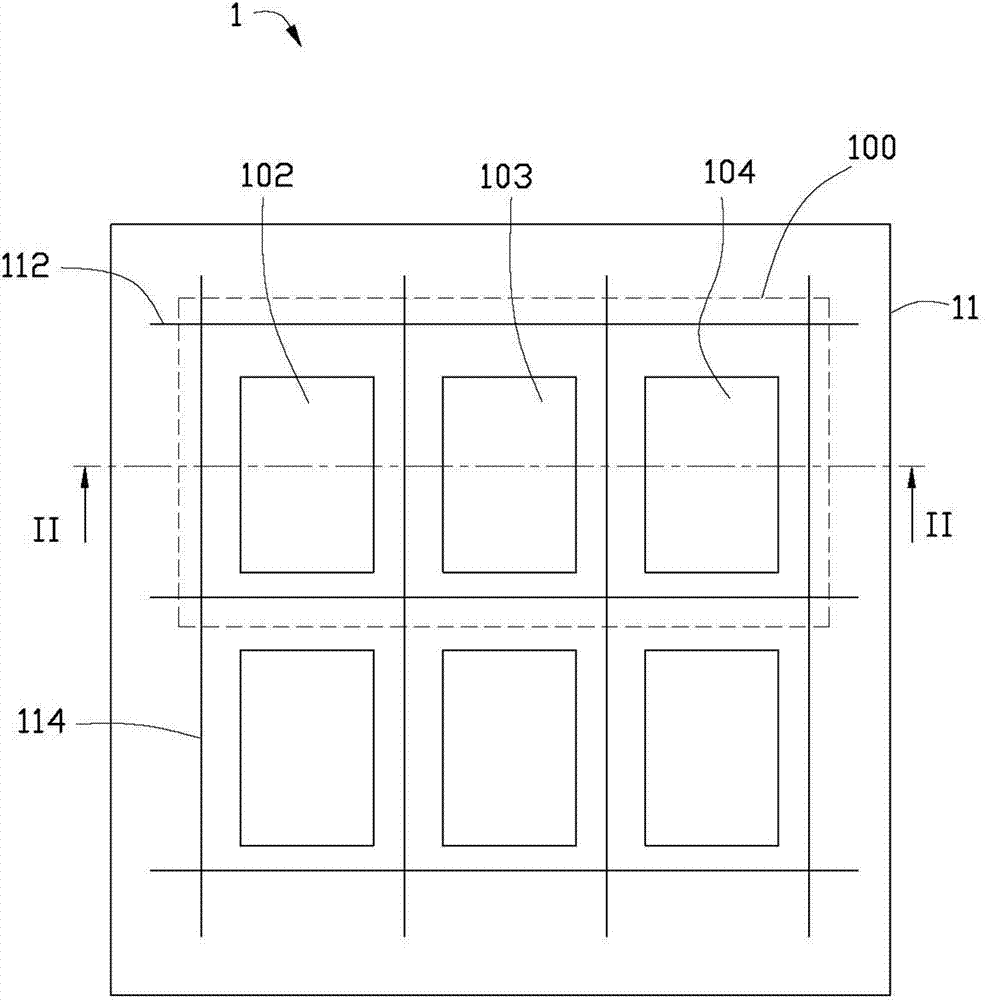

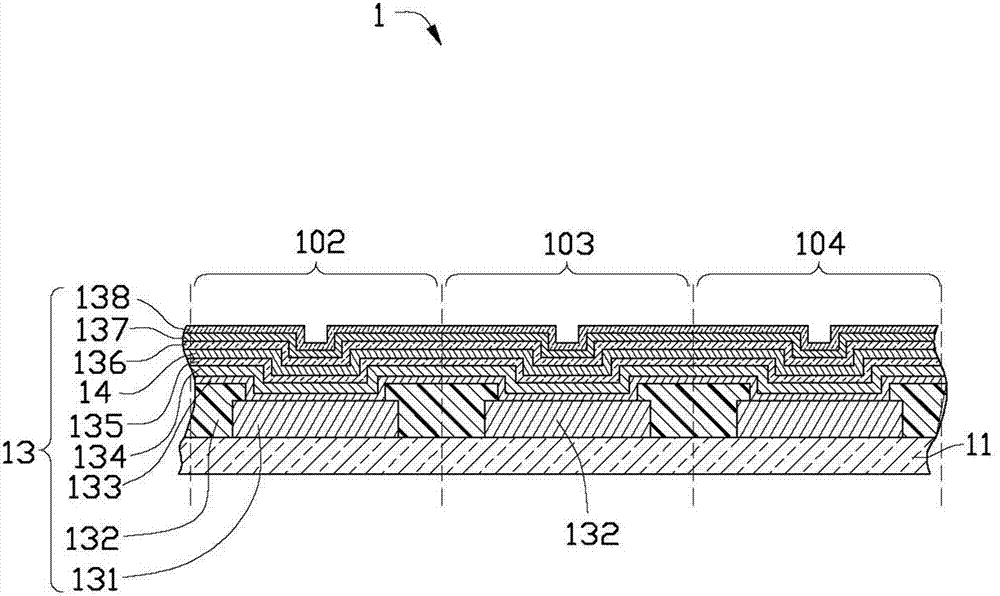

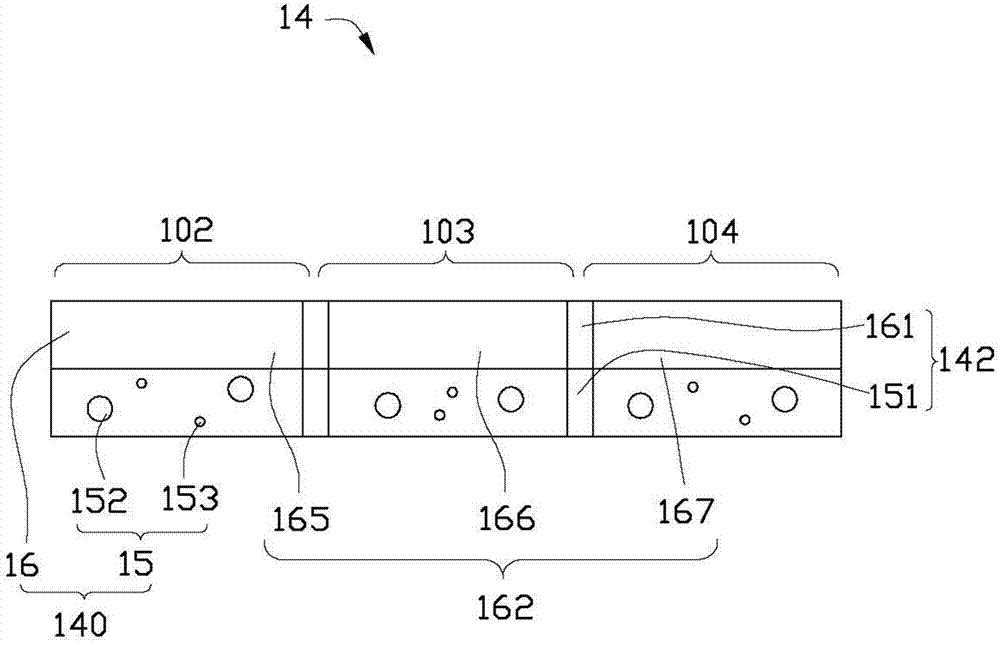

[0042] see Figure 1-2 , which is a schematic view of the first embodiment of the organic electroluminescence display panel 1 of the present invention. The organic electroluminescent display panel 1 is used to display images in full color, and defines a plurality of pixel areas 100, each pixel area 100 includes a first sub-pixel area 102 and a second sub-pixel area for emitting different color component lights. 103 and the third sub-pixel area 104.

[0043] The organic electroluminescent display panel 1 includes a substrate 11 , a plurality of scan lines 112 arranged parallel to each other on the substrate, and a plurality of data lines 114 parallel to each other and perpendicular to the scan lines 112 . The smallest area surrounded by the scan line 112 and the data line 114 is defined as a sub-pixel area. A plurality of first electrodes 131 formed of a transparent conductive material are independently formed in each sub-pixel region for each sub-pixel region.

[0044] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com