Double-elimination short-wave pass film system and color separation and color combination device

A short-wave-pass film system and film system technology, which is used in instruments, optical components, optics, etc. to achieve the effects of bright colors, improved image color saturation, and improved light energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

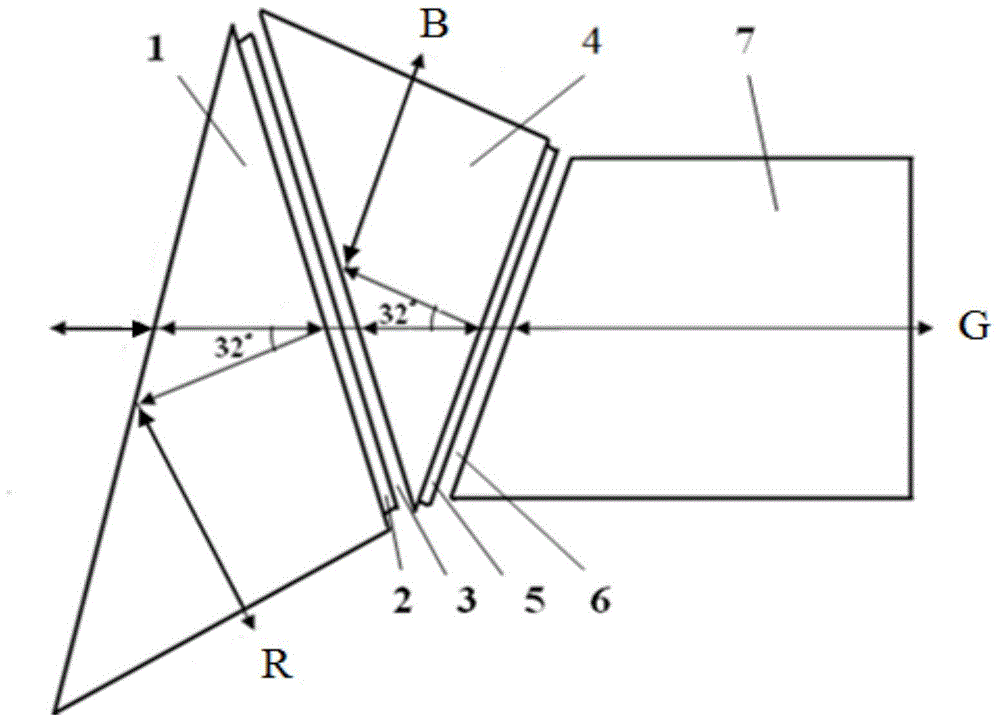

[0047] figure 1 It is a schematic diagram of the working principle of the Philips color separation and combiner. like figure 1 As shown, the Philips color separation combiner includes a red-transmissive blue-green prism 1 , a blue-transmissive green prism 4 and a green-transmissive prism 7 . The short-wave pass film system 2 is coated on the second prism surface of the anti-red-transparent blue-green prism 1, so that the incident white light can be divided into reflected red light and transmitted blue-green light. The film system 5 on the second prism surface of the anti-blue transparent green prism 4 can divide the incident blue-green light into reflected blue light and transmitted green light, so red (R), green (G) and blue (B) can be realized. ) color separation or color combination. figure 1 3 and 6 are air gaps.

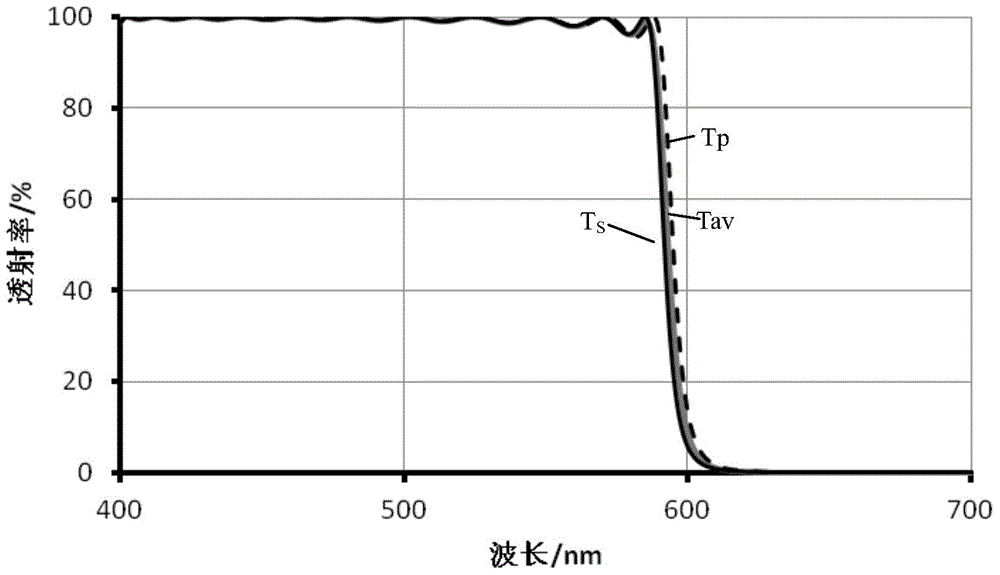

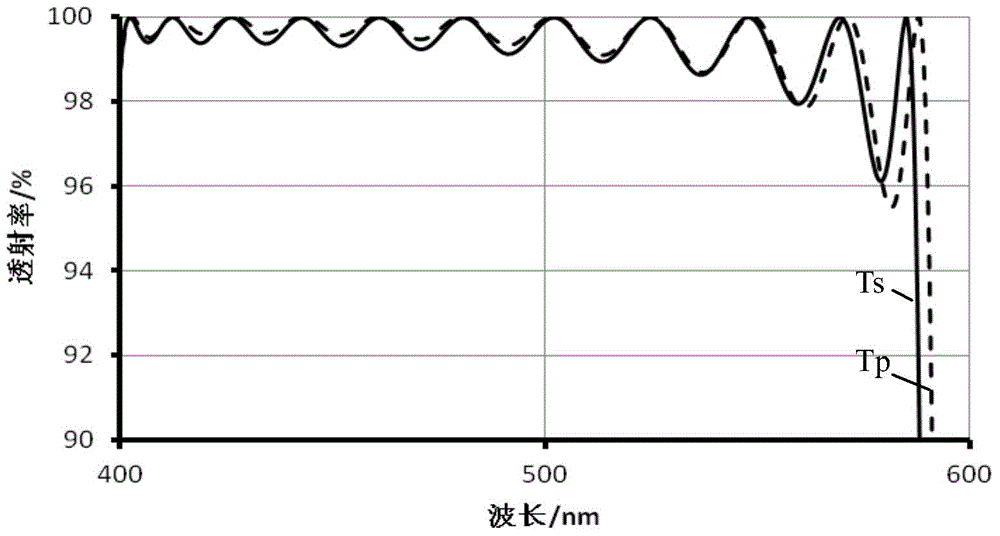

[0048] figure 2 and image 3 It is the current Philips color separation color combiner short-wave pass film system (ie figure 1 The spectral transmittan...

Embodiment 2

[0064] Figure 7 It is a schematic diagram of the working principle of the flat color separation and color combiner. like Figure 7 As shown, the flat color separation color combiner is composed of a red-transparent blue-green flat panel 8 and a blue-transparent green flat panel 9. The short-wave pass film system 10 is coated on the first surface of the anti-red and blue-green plate 8, so that the incident white light can be divided into reflected red light and transmitted blue-green light. Similarly, the film system 11 on the first surface of the blue-transmitting green plate 9 can divide the incident blue-green light into reflected blue light and transmitted green light. So red (R), green (G), blue (B) color separation or combination can be realized.

[0065] Figure 8 and Figure 9 It is the spectral transmittance curve of the short-wave pass film system of the currently used flat color separation color combiner, where Ts refers to the transmittance of s-polarized ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com