Mixing head having enhanced mixing performance and discharging device thereof

A technology of mixing performance and discharge device, applied in the field of mixing head and its discharge device, to achieve the effect of increasing eddy current and turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in more detail below with reference to the accompanying drawings.

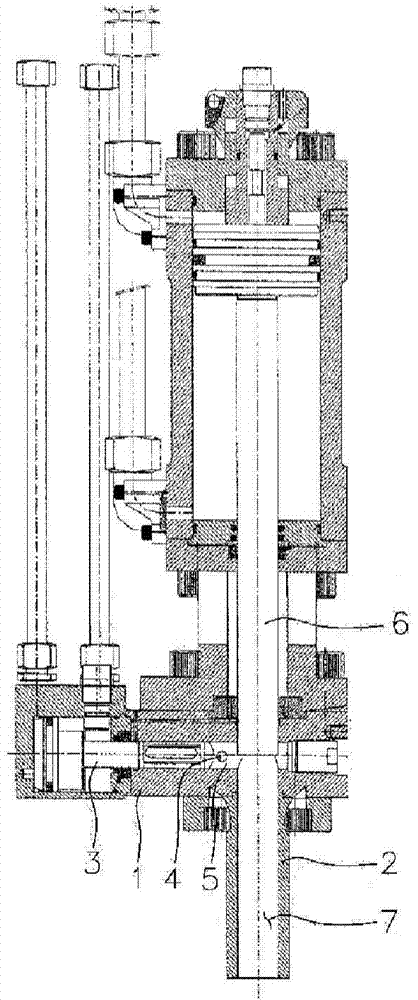

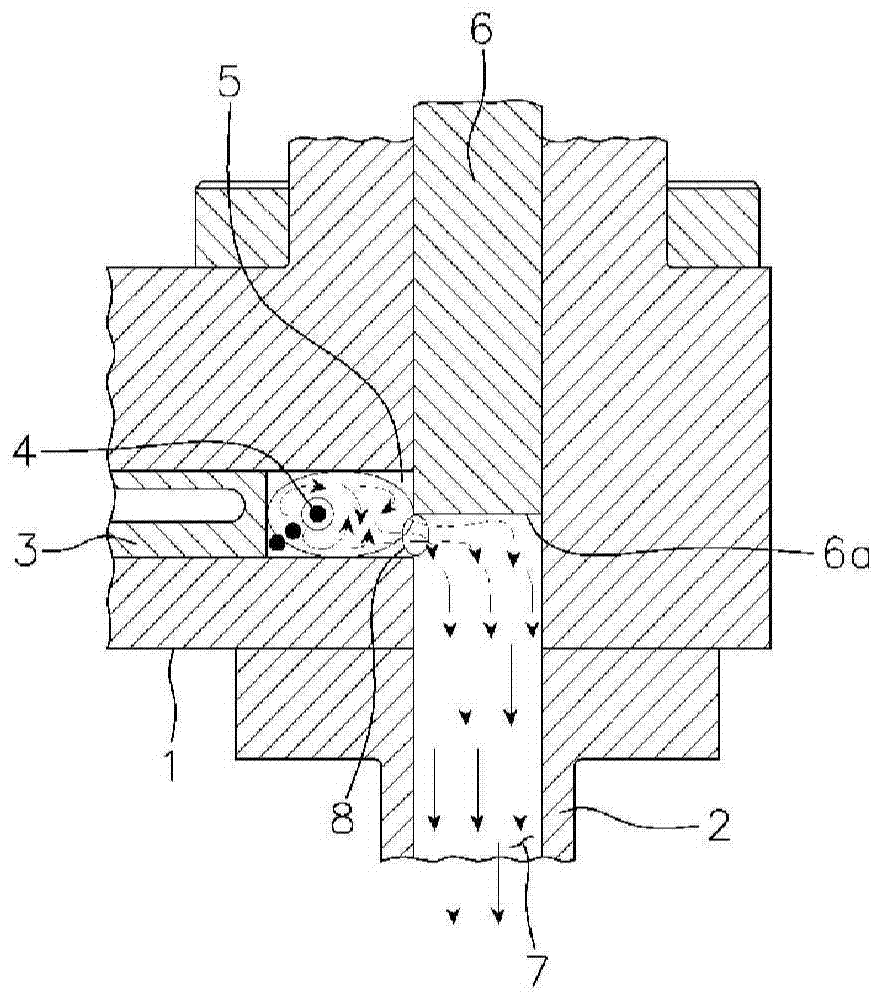

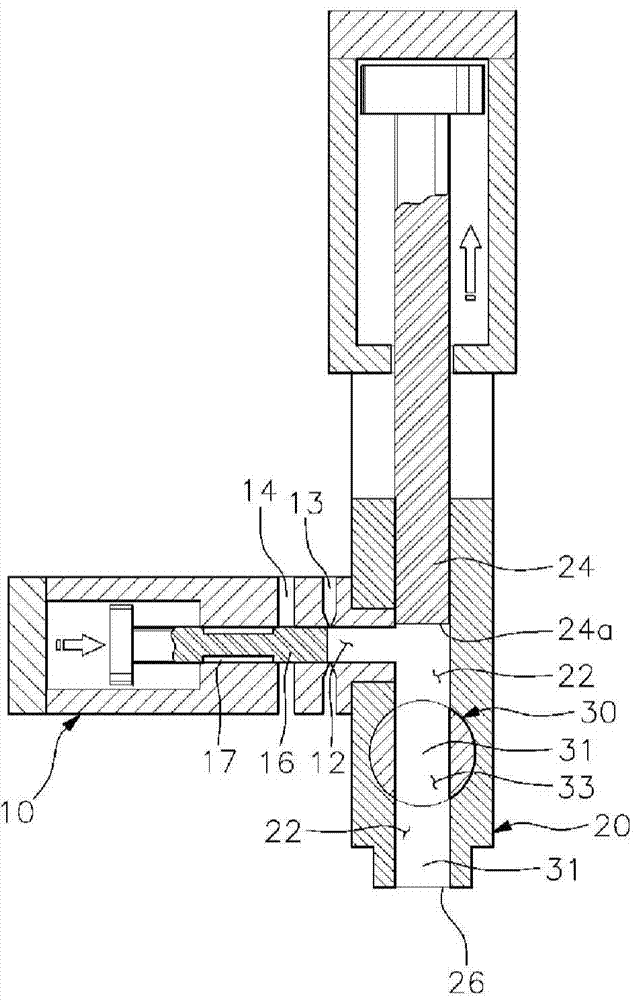

[0035] image 3 The illustrated mixing head according to the embodiment of the present invention is used to mix and discharge a plurality of materials supplied independently, and in particular, can be effectively used for high-pressure spraying of polyol and isocyanate for polyurethane foaming. Isocyanate to improve mixing efficiency.

[0036] The raw materials to be mixed in the present invention refer to liquid raw materials, including liquid raw materials such as gel (Gel).

[0037]The mixing head for mixing independently supplied multiple raw materials and discharging of the present invention comprises: a mixing part (10) comprising a mixing chamber (12), a supply port (13) and a return port (14), a mixing chamber piston ( 16), the supply port (13) and return port (14) are formed in each of the mixing chambers (12) of each of the raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com