Nutritive and health-care instant noodles and manufacturing method thereof

A production method and instant noodle technology are applied in the fields of instant noodles, nutritious and health-care instant noodles and their production, which can solve problems such as harm and easy breeding of microorganisms, and achieve the effects of simple process, high nutritional value, and supplementary grain yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

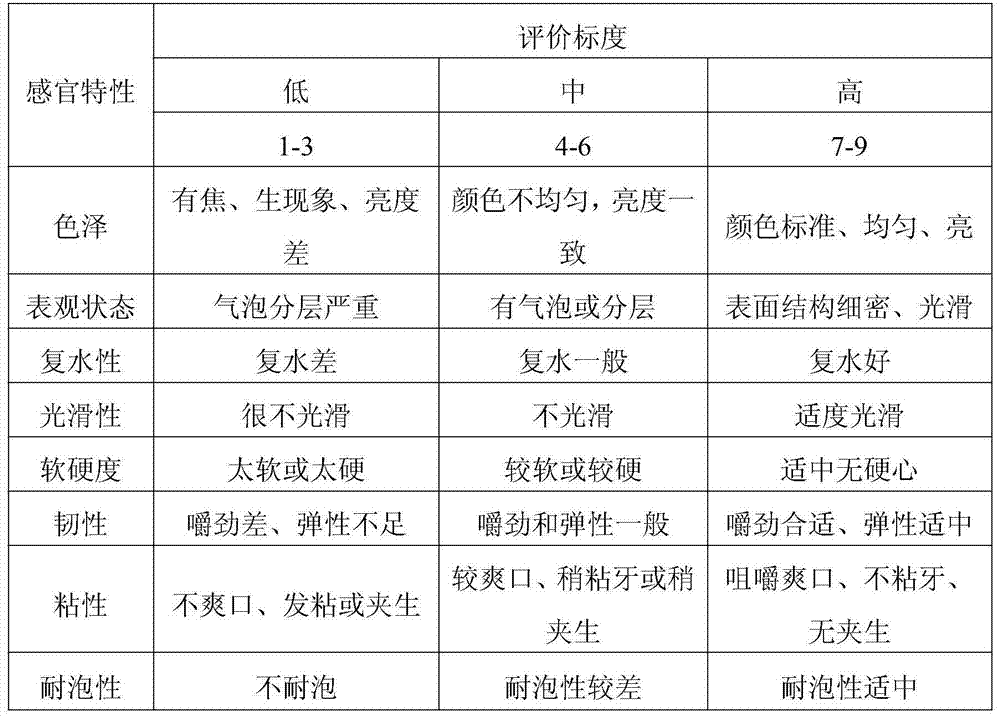

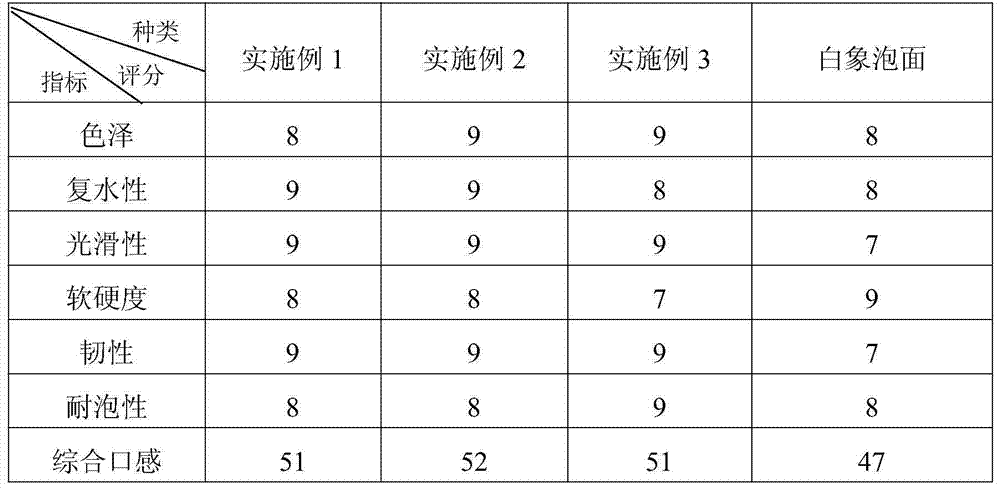

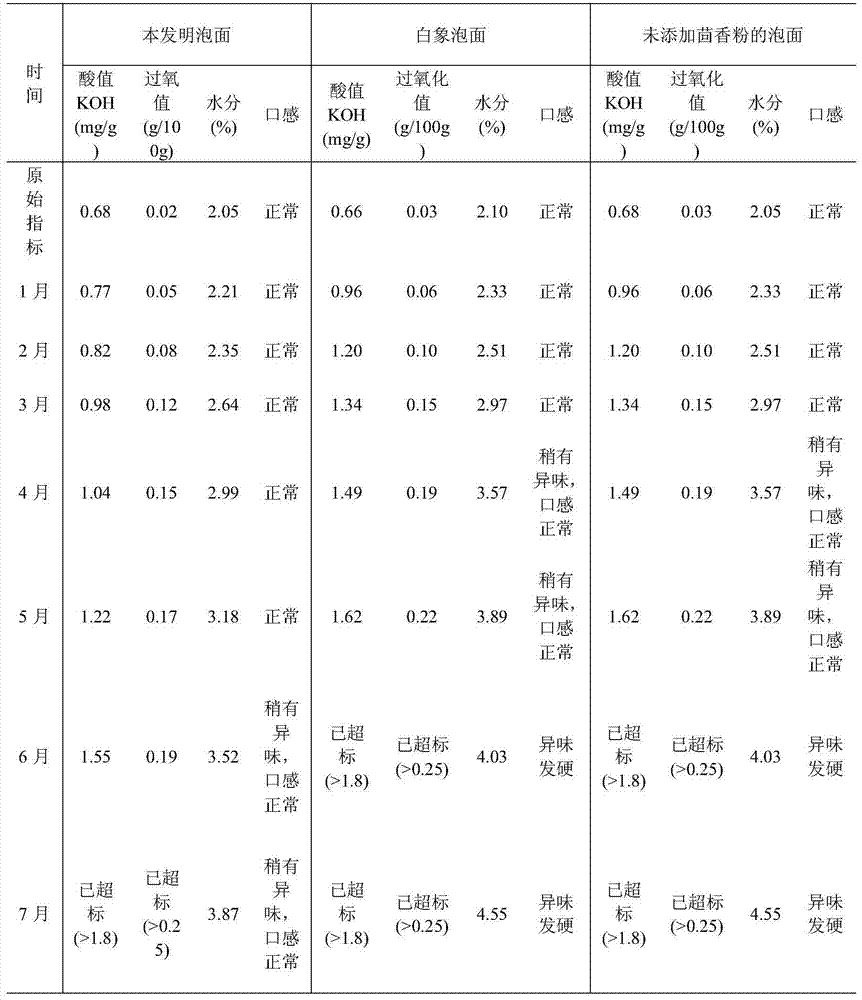

Examples

Embodiment 1

[0035] (1) Kneading noodles: 60 parts of wheat flour, 60 parts of alfalfa powder, 20 parts of brown sugar, 6 parts of motherwort powder, 6 parts of fennel seed powder, 3 parts of edible salt, 2 parts of soda ash, 4 parts of 5-flavored nucleotide disodium 1 part and 30 parts of water are uniformly mixed, and stirred to form a dough with processability, the stirring time is 15 minutes, and the temperature is 25°C;

[0036] (2) Ripening: put the dough in step (1) into the ripening tray to complete the ripening, and the ripening time is 15 minutes;

[0037] (3) Composite calendering: send the matured dough in step (2) into the feeder, and roll the dough into two dough sheets under the action of the feeder, and then compound into one dough sheet through the composite roller;

[0038] (4) shredded forming: the noodle belt obtained in step (3) is passed through a shredder at a high speed, cut into noodles and made into a wave crest erected, and the front and back wave crests lean aga...

Embodiment 2

[0044] (1) Kneading noodles: 80 parts of wheat flour, 40 parts of alfalfa powder, 10 parts of brown sugar, 10 parts of motherwort powder, 10 parts of fennel seed powder, 6 parts of edible salt, 4 parts of soda ash, 5-flavored nucleotide disodium 2 1 part and 50 parts of water are evenly mixed, and stirred to form a dough with processing properties, the stirring time is 15 minutes, and the temperature is 25°C;

[0045] (2) Ripening: put the dough in step (1) into the ripening tray to complete the ripening, and the ripening time is 15 minutes;

[0046] (3) Composite calendering: send the matured dough in step (2) into the feeder, and roll the dough into two dough sheets under the action of the feeder, and then compound into one dough sheet through the composite roller;

[0047] (4) shredded forming: the noodle obtained in step (3) is passed through a shredder at a high speed, cut into noodles and made into a wave crest erected, and the front and rear crests lean against each oth...

Embodiment 3

[0053](1) Kneading noodles: 70 parts of wheat flour, 50 parts of alfalfa powder, 15 parts of brown sugar, 8 parts of motherwort powder, 8 parts of fennel seed powder, 5 parts of edible salt, 3 parts of soda ash, 3 parts of 5-flavored nucleotide disodium 1 part and 40 parts of water are evenly mixed, and stirred to form a dough with processing properties, the stirring time is 15 minutes, and the temperature is 25°C;

[0054] (2) Ripening: put the dough in step (1) into the ripening tray to complete the ripening, and the ripening time is 15 minutes;

[0055] (3) Composite calendering: send the matured dough in step (2) into the feeder, and roll the dough into two dough sheets under the action of the feeder, and then compound into one dough sheet through the composite roller;

[0056] (4) shredded forming: the noodle obtained in step (3) is passed through a shredder at a high speed, cut into noodles and made into a wave crest erected, and the front and rear crests lean against ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com