Hammering type walnut hull breaking machine with groove chain transmission device

The technology of chain transmission and shell breaking machine is applied in the field of walnut shell breaking equipment and hammer-type walnut shell breaking machine, which can solve the problems of difficulty in meeting the demand of nuts, low processing efficiency, and poor control of percussion force. To achieve the effect of easy promotion and application, convenient operation and maintenance, and improved shell breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

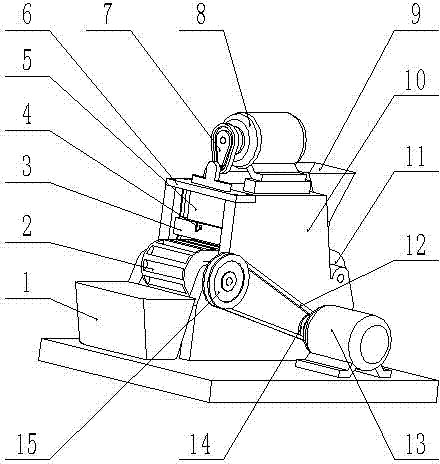

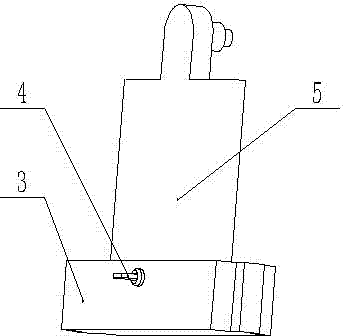

[0015] see Figure 1~Figure 4 A hammer-type walnut shelling machine with a groove chain transmission device is composed of a machine base, a low-speed motor installed on the machine base, a feeding and conveying device, a shell breaking device, a collecting device and a power transmission device. Motor II (13) transmits the power to the large pulley (15) through the small pulley (14) and the V-shaped belt (12), and the large pulley (15) drives the sprocket (11) to rotate so that the transmission chain (2) Rotate to convey the material falling from the hopper (9) to the conveyor chain (2); motor I (8) drives the cam (7) to rotate, driving the guide rod (5) and the hammer head (3) connected to it to move up and down.

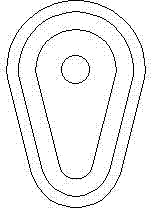

[0016] The chain links of the transmission chain (2) are provided with arc-shaped elongated grooves, and the cams (7) have slide grooves.

[0017] The hammer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com