A small mixed water washing and wheat washing machine

A small technology for washing wheat washer with water, applied in the field of wheat washing machine, which can solve the problems of pollution and large water consumption, and achieve the effects of reducing pollution, high washing rate and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

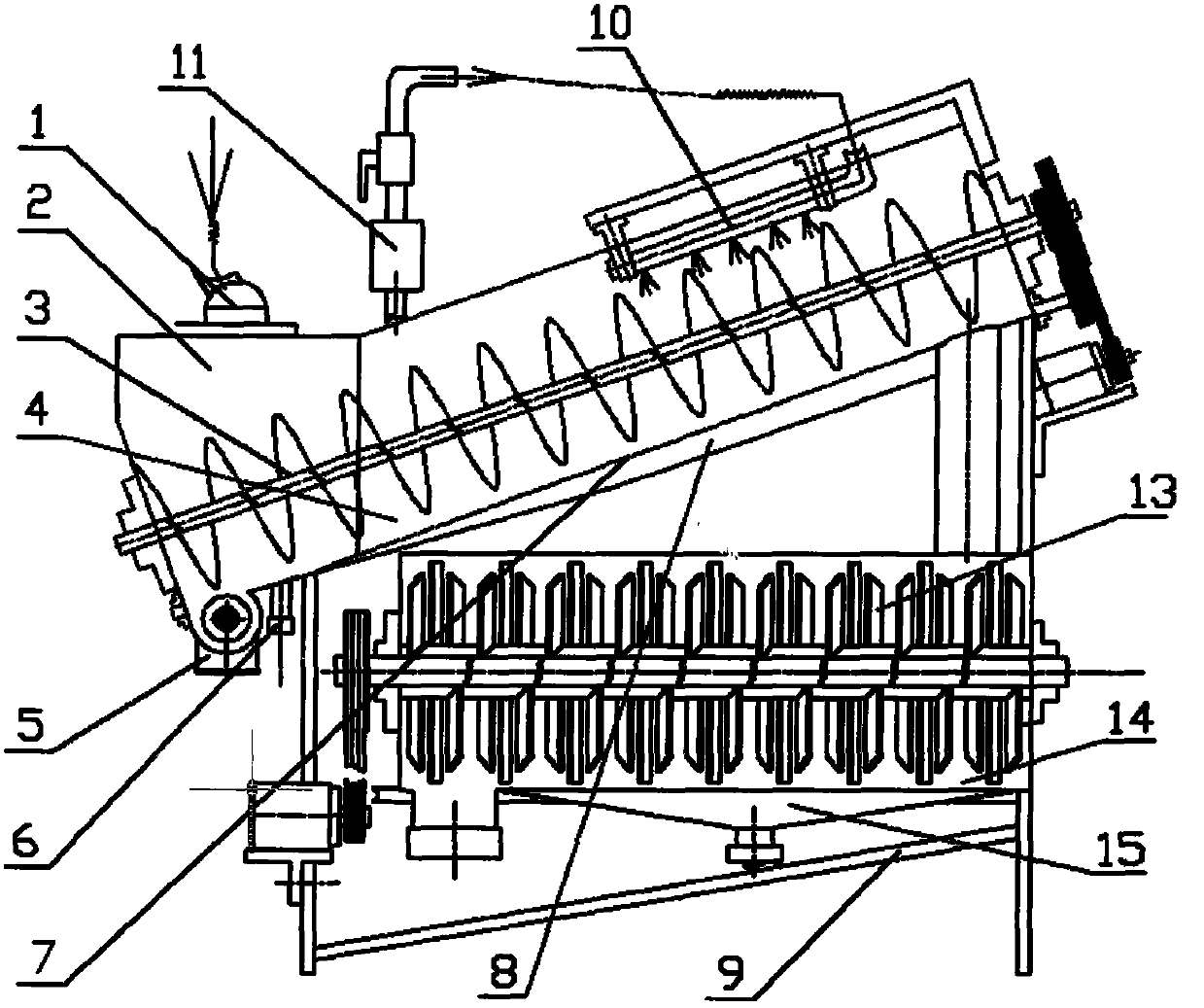

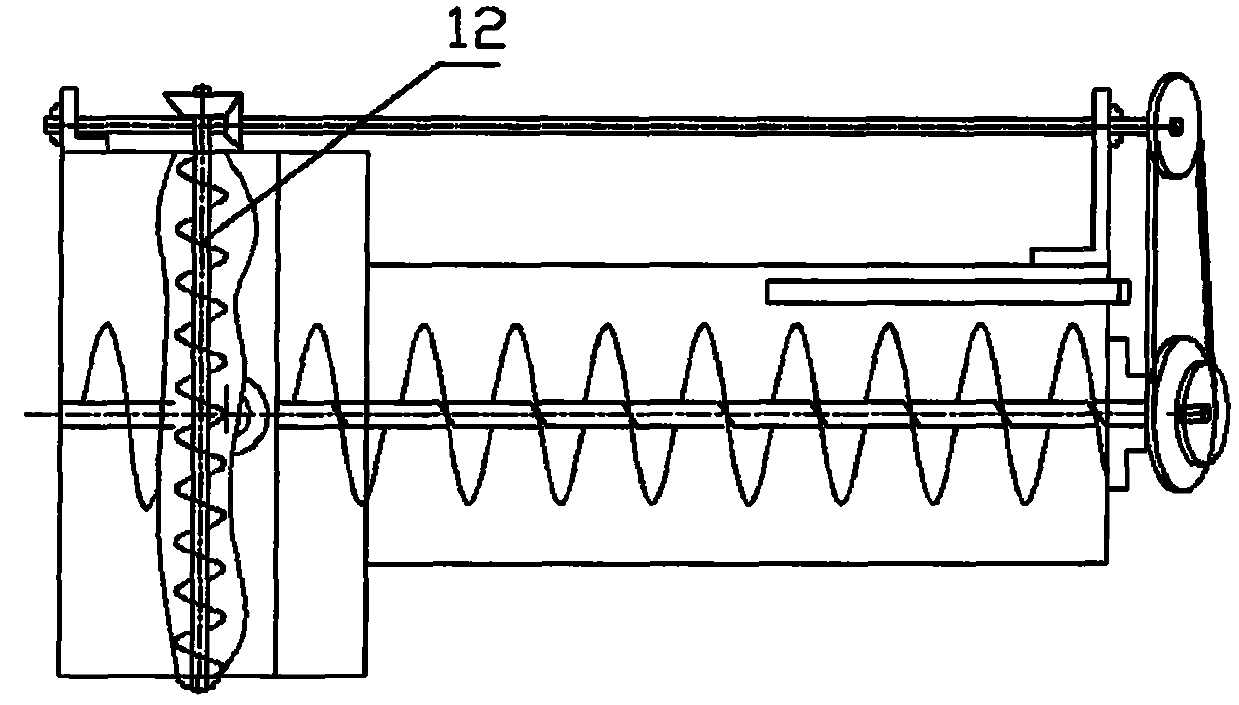

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 and 2 Shown, a kind of small-scale mixed washing wheat washing machine comprises frame (9), feeder (1), elutriation tank (2), elutriation auger (3), auger groove (4), screen cloth (7), return tank (8), spray pipe (10), flow monitoring controller (11), gravel auger (12), sand collection box (5), sewage pipe (6), dehydration cylinder (14 ), waste water collector (15);

[0022] The elutriation tank (2) is installed horizontally and longitudinally on the frame (9) and communicates with the lower end of the horizontally inclined auger tank (4);

[0023] The inclined angle of the tank body of the auger tank (4) is 25 ± 2 ° and is installed on the frame (9). , below the screen (7) is a water return tank (8) that is used to collect the water drained by the screen (7) and flows back to the elutriation tank (2);

[0024] The auger (3) is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com