Automatic rice seedling plate overlapping device

A technology for seedling trays and stacking trays is applied in the field of automatic tray stacking devices for rice seedling trays, which can solve the problems of low efficiency, high cost of hard trays, affecting uniformity and the like, and achieve the effects of high efficiency, simple and compact structure, and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

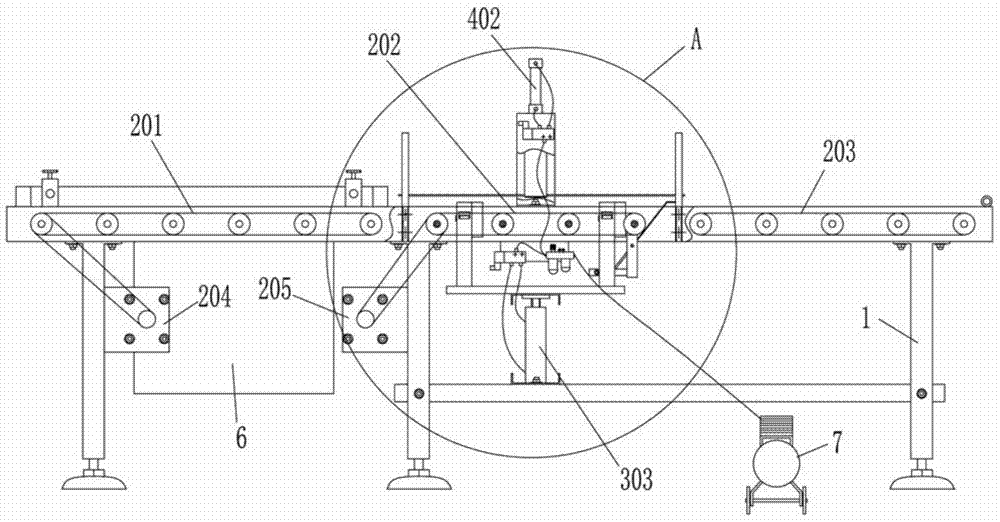

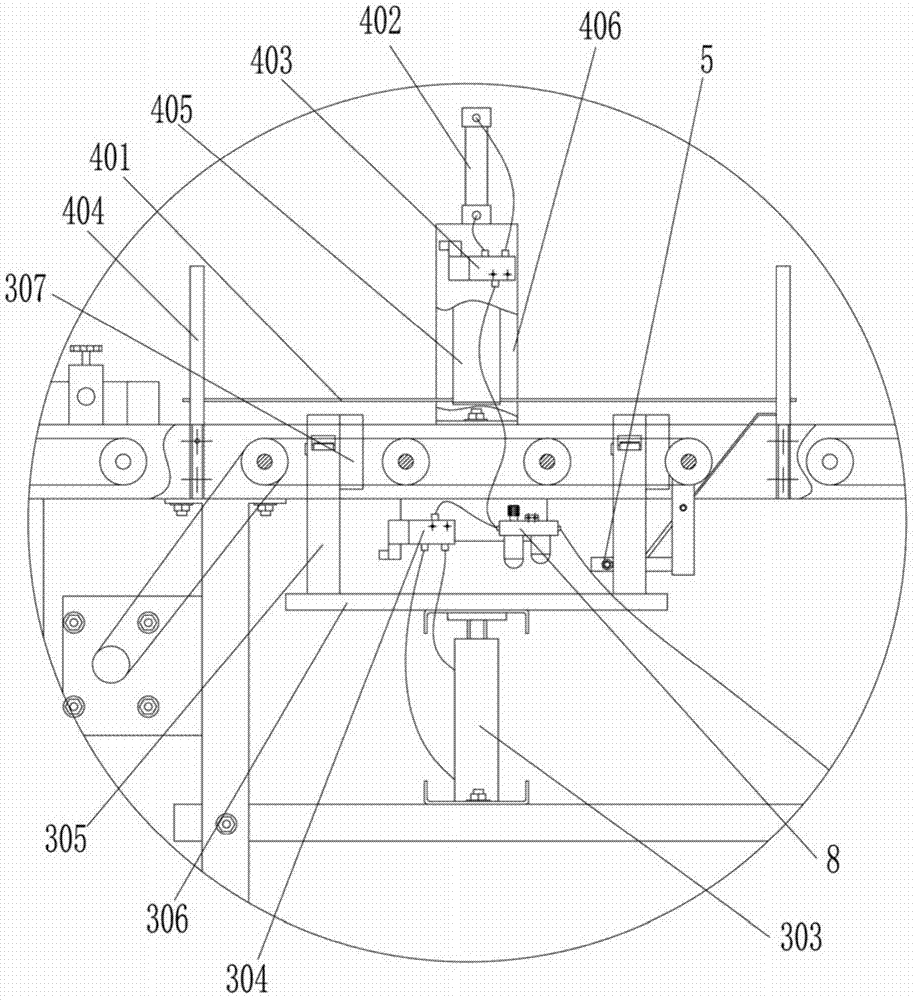

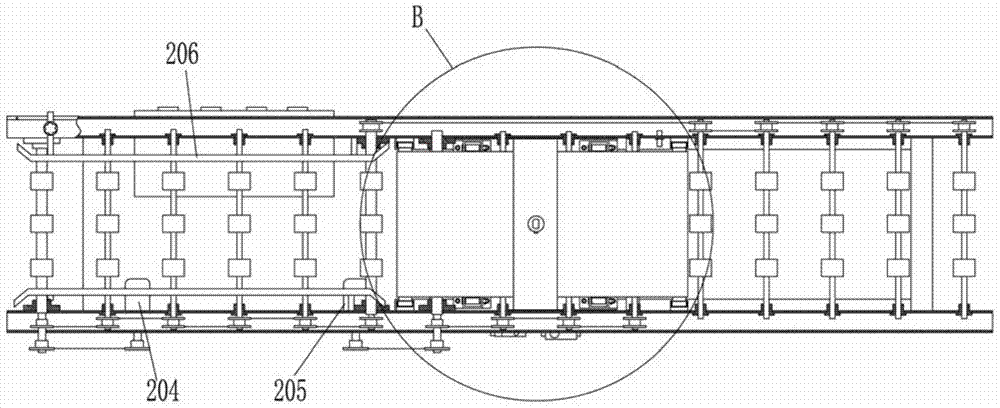

[0024] Such as Figure 1 to Figure 7 As shown, the rice seedling tray automatic stacking device described in the present embodiment includes a frame 1, an air compressor 7 and a seedling tray conveying mechanism, a seedling tray stacking mechanism, and a soil planting mechanism respectively mounted on the frame 1. Leak-proof mechanism, tray sensor 5, controller PLC6, wherein, the seedling tray stacking mechanism is provided with a turning finger 301 installed by a pin 302, and the turning finger 301 can rotate around the pin 302, and can automatically reset by gravity , the turning finger 301 lifts up and down under the effect of the seedling tray lifting cylinder 303 of the seedling tray stacking mechanism. When descending, when the turning finger 301 hits the edge of the tray to be stacked and transported again by the seedling tray conveying mechanism, the turning finger 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com