Automatic control system for rotational flow well travelling crane

An automatic control system and control system technology, applied in the direction of load suspension components, design optimization/simulation, special data processing applications, etc., can solve the problems of long cycle and high development cost, and achieve the effect of long cycle and high development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

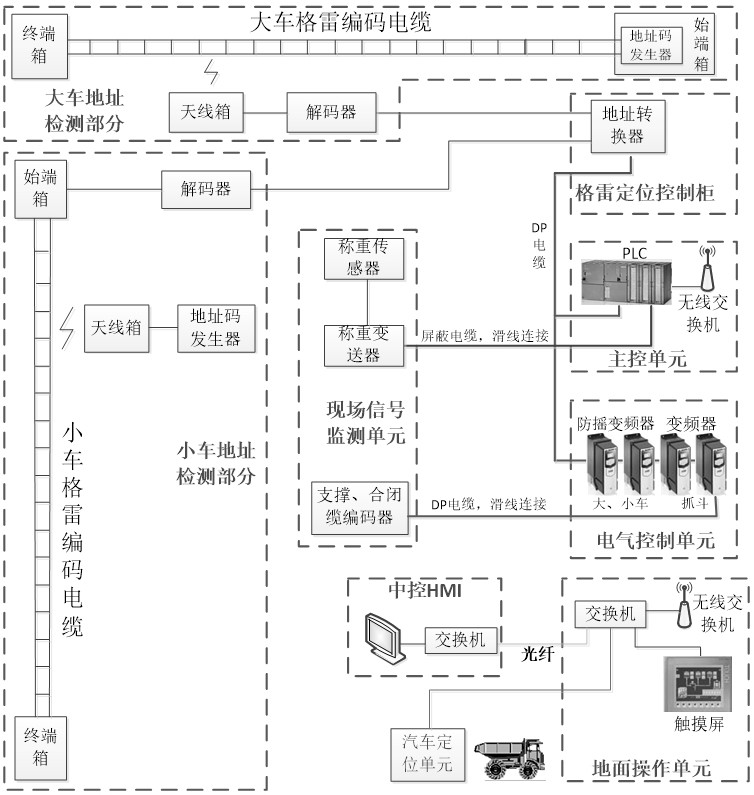

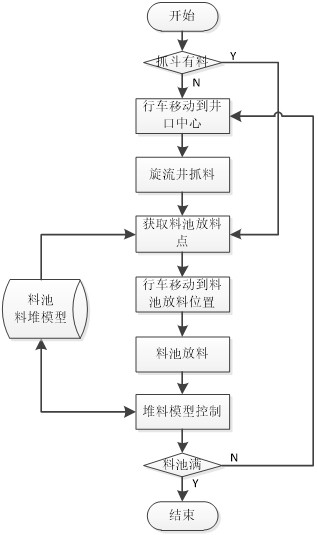

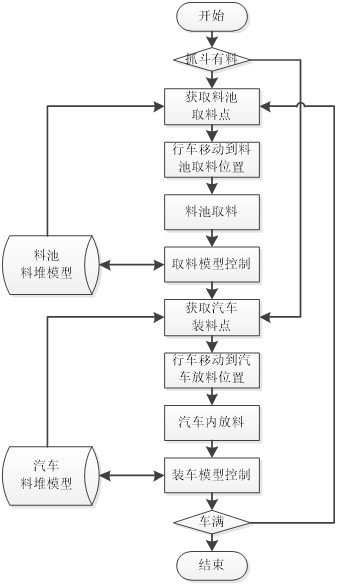

[0027] The invention is an automatic driving control system of a swirl well, which adopts the PLC automatic control system technology to realize the detection of signals such as the positioning of the driving, and develops the automatic stacking of the stockpile model by establishing a stockpile model for the stockpile and the vehicle The material control model and reclaiming control model realize the automatic reclaiming and stacking of iron oxide scale piles; through the vehicle positioning technology and loading control model, the automatic loading function of materials is realized. Through the application of these technologies, the automatic grabbing and storage of iron oxide scale slag in the swirl well and the automatic grabbing and loading of materials in the material pool are realized.

[0028] Such as figure 1 As shown, the embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com