Pre-Molded Plastic Water Meter Wells

A technology for water meter wells and plastics, which is applied in water conservancy projects, underwater structures, measuring devices, etc., can solve the problems of not being able to be sealed together, heavy weight, poor load-bearing capacity, etc., to reduce construction time, light weight, and load-bearing capacity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

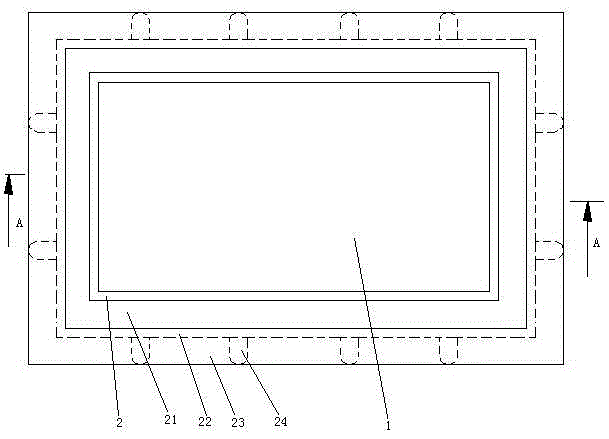

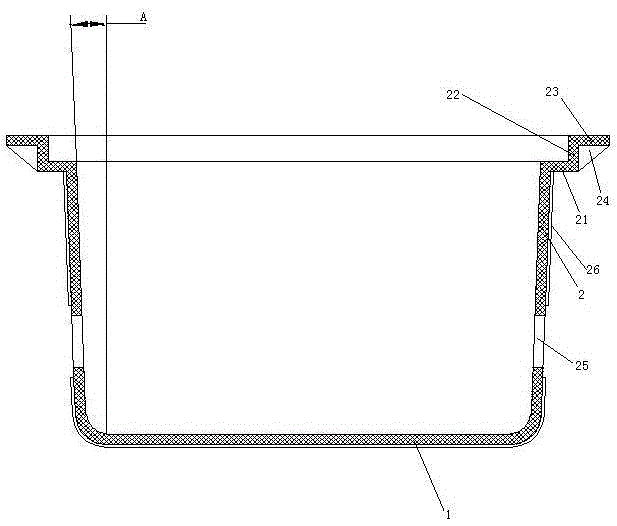

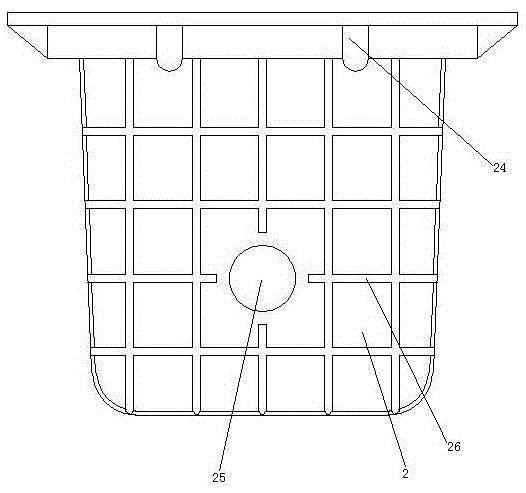

[0035] Embodiment one, see figure 1, a prefabricated plastic water meter well, comprising a bottom wall 1 and a side wall 2 connected to the bottom wall. The bottom wall 1 is a flat bottom structure. The side wall 2 is square tubular. Both the bottom wall 1 and the side wall 2 are made of plastic. The bottom wall 1 and the side wall 2 have an integral structure, that is, they are injection molded together. The upper end of the side wall 2 is turned outward to form a well cover bearing ring 21 , the radially outer end of the well cover bearing ring 21 is turned upward to form a well cover stop ring 22 , and the upper end of the well cover stop ring 22 is turned outward to form a booster ring 23 . Between the outer peripheral surface of the well cover limiting ring 22 and the lower end surface of the booster ring 23, several booster ribs 24 are arranged along the circumferential direction of the well cover limiting ring.

[0036] see figure 2 , The left and right ends of t...

Embodiment 2

[0039] Embodiment two, the difference with embodiment one is:

[0040] see Figure 5 , The pipe hole 25 is provided with a seal 6 . The sealing member 6 includes an elastic sealing tube 61 and a connecting ring 62 . The connecting ring 62 and the elastic sealing tube 61 are of an integral structure and are hermetically connected. The elastic sealing tube 61 is a reversible structure. The elastic sealing tube 61 extends toward the outside of the side wall 2 . The inner surface 611 of the elastic sealing tube is a conical surface. The outer surface 612 of the elastic sealing tube is a conical surface. The outer radius of one end of the elastic sealing tube 61 connected with the connecting ring is large, and the outer radius of the other end is small. One end of the elastic sealing tube 61 connected to the connecting ring has a large opening area, and the other end has a small opening area. There is an arc surface transition between the connecting ring 62 and the elastic s...

Embodiment 3

[0047] Embodiment three, the difference with embodiment two is:

[0048] see Figure 9 , also includes a water meter support plate 7. The water meter support plate 7 is supported on the inner surface of the bottom wall 1 by several support rods 9 . The water meter support plate 7 is disconnected with the side wall 2.

[0049] see Figure 10 , the support rod 9 is a tubular structure. The outer peripheral surface of the support rod 9 is provided with several shape-changing guide grooves 91 . The shape-changing guide grooves 91 are axially distributed along the support rod 9 . The inner peripheral surface of the support rod 9 is provided with several inner deformation guide grooves 92 . The inner deformation guide grooves 92 are axially distributed along the support rod 9 . Both the shape deformation guide groove 91 and the inner deformation guide groove 92 are annular grooves extending along the circumferential direction of the support rod 9 . The shape deformation guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com