Brake assembly of tractor

A technology for brakes and tractors, applied in the directions of hydraulic drum brakes, slack adjusters, manual starting devices, etc., which can solve the problem that the connection between the brake cylinder and the brake shoes is not stable enough, the handle exerts a large pulling force, and there is no gap. Adjustment and other problems, to achieve the effect of automatic adjustment of clearance, increased stability and comfort, and reduced hand tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

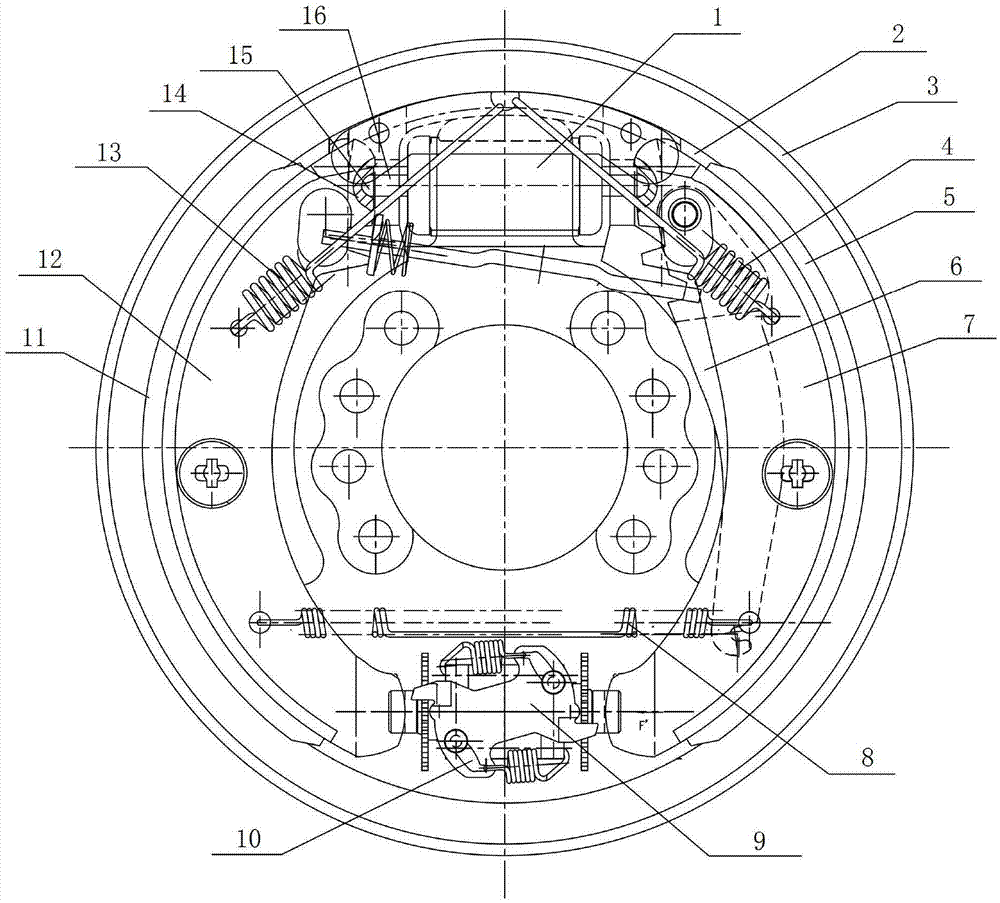

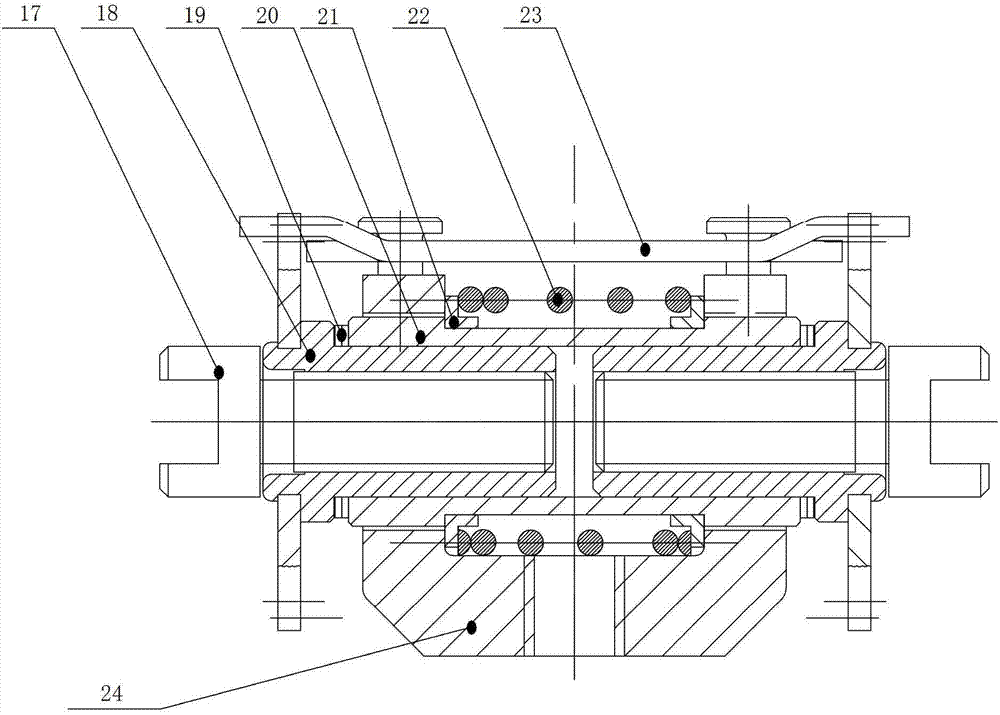

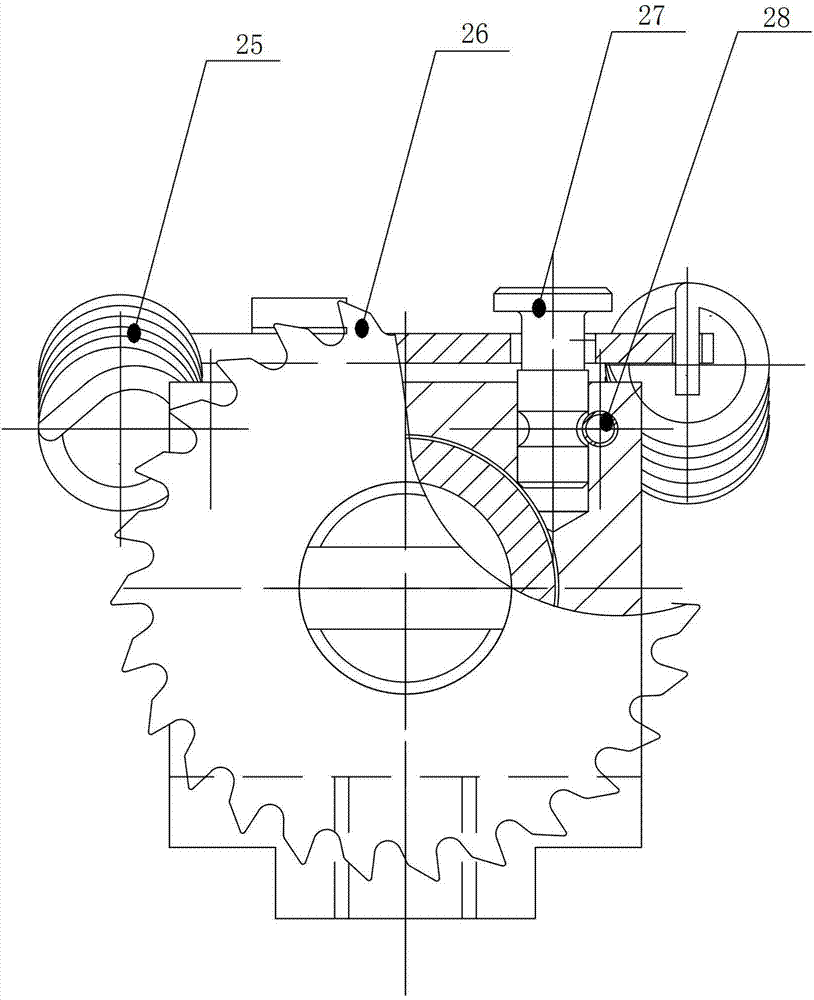

[0025] Such as figure 1 In the described embodiment, a tractor brake assembly includes a base plate 2, a brake cylinder 1, a left brake shoe 12, a right brake shoe 7, a brake drum 3, a left friction plate 11, and a right friction plate 5. The slack adjuster assembly 9 and the parking brake assembly 6, the base plate 2 is installed in the middle of the brake drum 3, the brake cylinder 1, the left brake shoe 12 and the right brake shoe 7 are installed on the base plate 2 , the left brake shoe 12 and the right brake shoe 7 are respectively placed on the left and right sides of the brake cylinder 1, and the brake cylinder 1 is installed between the upper end of the left brake shoe 12 and the upper end of the right brake shoe 7, The gap adjuster assembly 9 is installed between the lower end of the left brake shoe 12 and the lower end of the right b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com