A hydraulic loading device and method for model testing

A loading device and model test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of human error in measuring model water pressure, tedious recording of model water pressure at different time points, etc. Avoid model water pressure data distortion, good overall sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

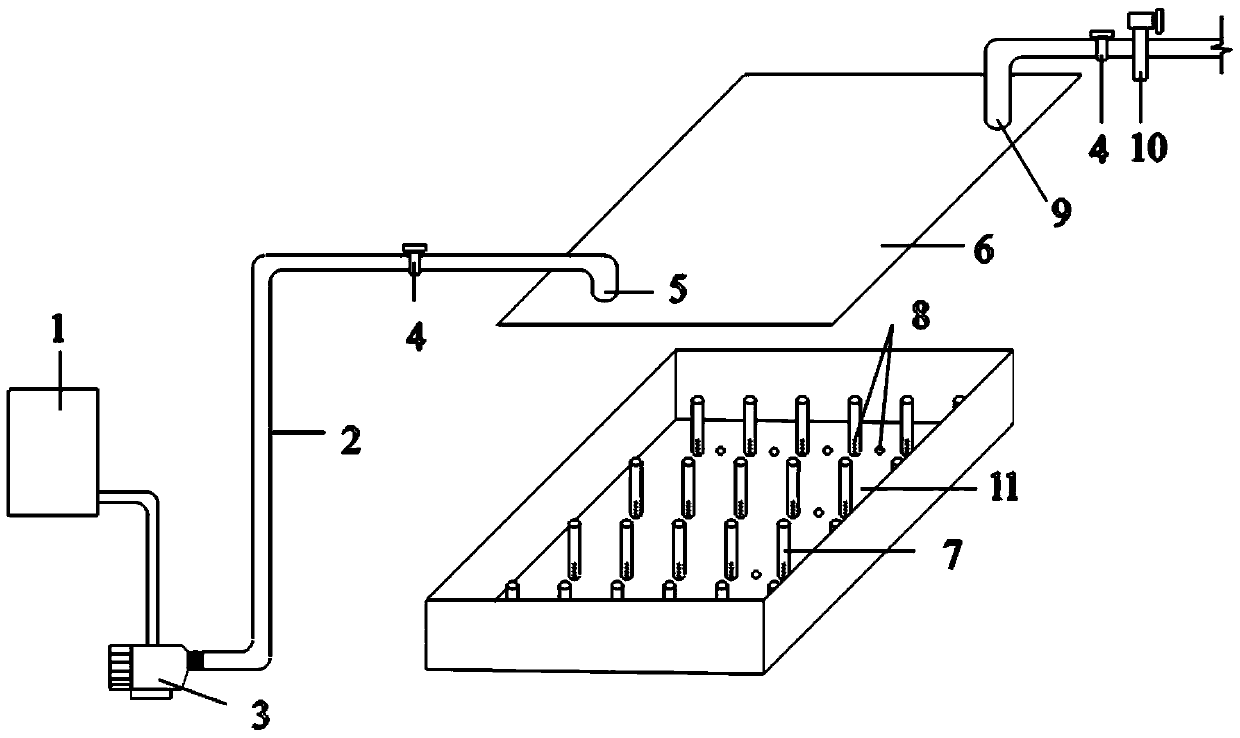

[0030] Such as figure 1 As shown, the hydraulic loading device used for the model test includes a hydraulic supply device, a water storage device on the upper part of the model body and a hydraulic pressure measuring device. The water pressure supply device is composed of pressurized water pump 3, water storage tank 1 and supporting pipeline 2. The function of water storage tank 1 is to provide constant water supply. The 50m lift that pressurized water pump 3 can provide meets the hydraulic pressure requirements required for the test. The water storage device on the upper part of the model body is made up of permeable plates 11 and 24 supporting water guide columns 7, and the bottom plate of the water storage device and each support water guide column 7 are all equipped with water permeable holes 8; the top of the support water guide column 7 is a jack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com