Automatic gas sample retention device

A fully automatic, sample retention technology, applied in the direction of analytical materials, instruments, etc., can solve the problems of inaccurate verification and analysis results, sample gas pollution, missed sample gas, etc., to save labor costs, improve accuracy, and ensure purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

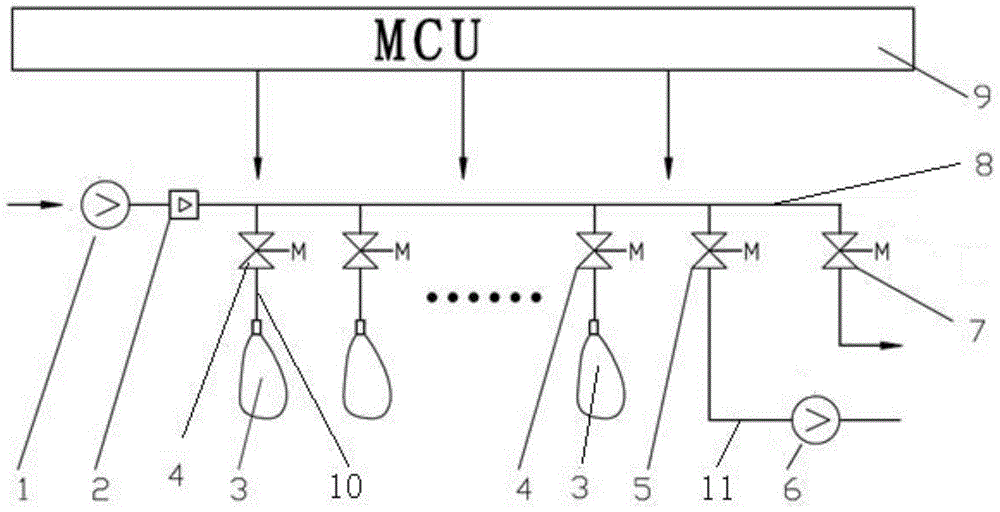

[0027] Example: such as figure 1 As shown, it is a specific embodiment of the automatic gas sample retention device of the present invention, which has a sample gas pump 1, and the input end of the sample gas pump 1 is used to connect to the same sample gas pipeline (not shown in the figure), The output end is connected to the sampling pipe 8 through a flowmeter 2, and the end of the sampling pipe 8 is provided with an exhaust valve 7 for evacuating the gas in the pipe. The sampling pipe 8 between the flow meter 2 and the emptying valve 7 is provided with an air bag connection area, on which a number of air bags 3 are connected through branch pipes 10 (the number of air bags depends on actual needs), and each branch pipe 10 Both are equipped with communication valve 4.

[0028] The sampling pipe 8 in the present embodiment is also connected with an air bag cleaning device, and the device is composed as follows: there is an air pump 6 connected to the sampling pipe 8 by an eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com