Magnetic liquid magnetic induction intensity sensor

A technology of magnetic induction intensity and magnetic liquid, applied in the field of sensors, can solve the problems of intolerance to shock and vibration, high requirements for working conditions, and weak robustness. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

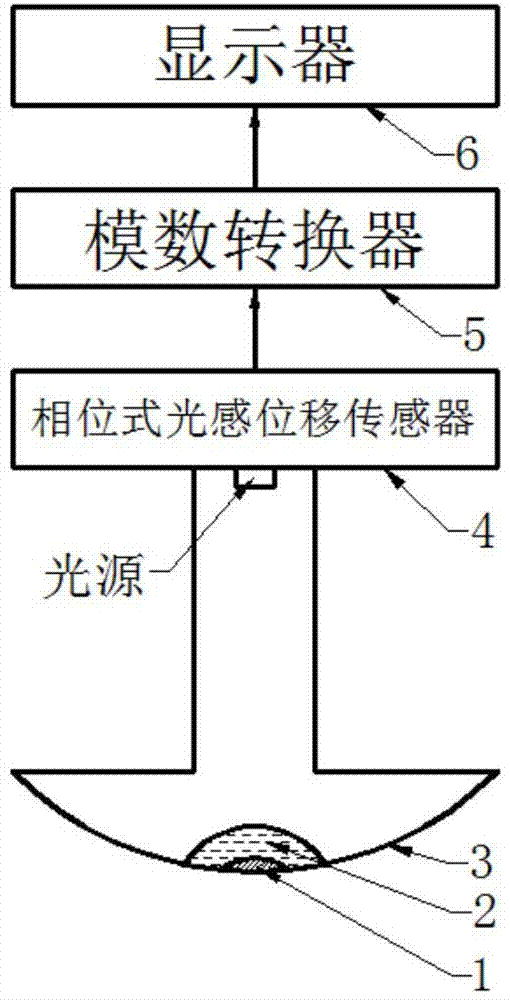

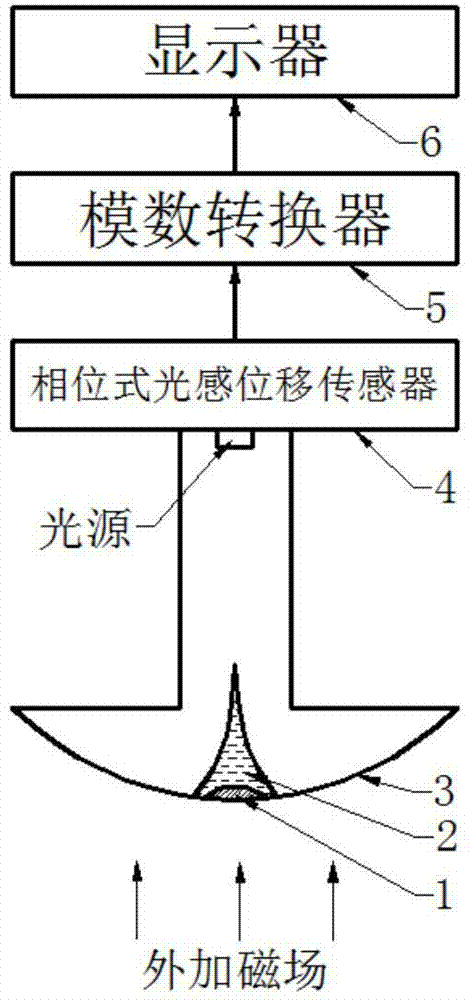

[0015] to attach figure 1 And attached figure 2 The present invention will be further described for the specific embodiment:

[0016] A sensor for the magnetic induction intensity of a magnetic liquid, the sensor comprising: a weak magnet 1, a magnetic liquid 2, a magnetic field probe 3, a phase type optical displacement sensor 4, an analog-to-digital converter 5, and a display 6.

[0017] Connections between the parts of the sensor:

[0018] Fix the weak magnet 1 at the center of the arc-shaped bottom surface of the magnetic field probe 3, and then inject the magnetic liquid 2 into the arc-shaped bottom surface of the magnetic field probe 3. The weak magnet 1 is used to absorb the magnetic liquid 2, so that the magnetic liquid 2 is always located in the magnetic field probe 3 at the center of the arc-shaped bottom surface. Then install the phase-type photosensitive displacement sensor 4 at the top of the magnetic field probe 3 facing the magnetic liquid 2, the light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com