Method for etching silicon on the back of wet bench

An acid tank, backside technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of abnormal appearance, difficult to take away silicon wafers in time, etc., to reduce chromatic aberration, improve economic efficiency, and improve process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

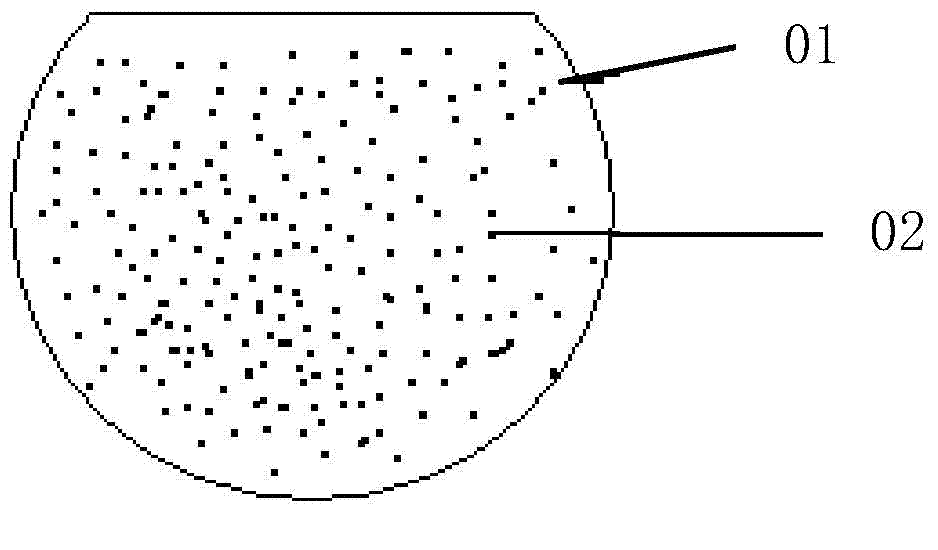

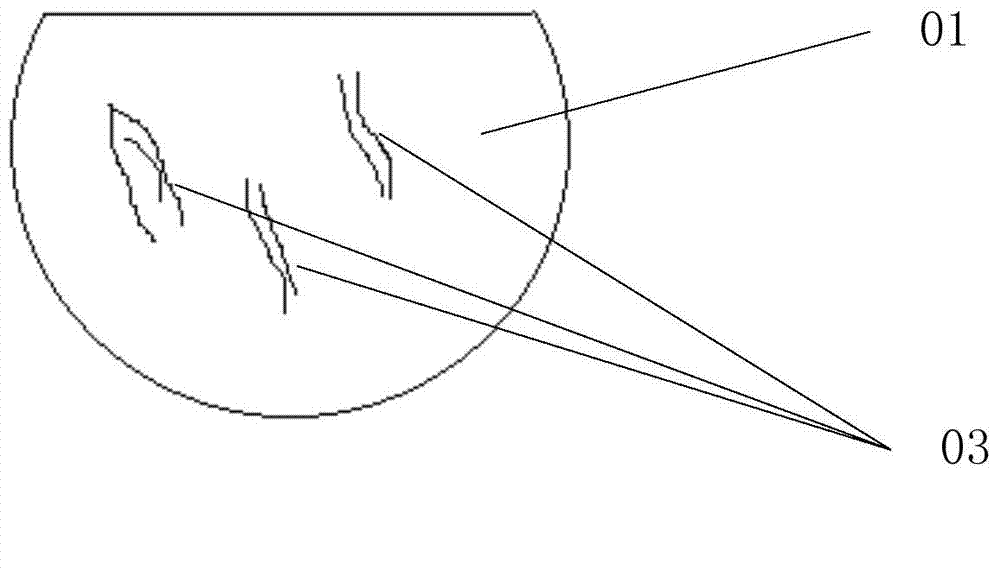

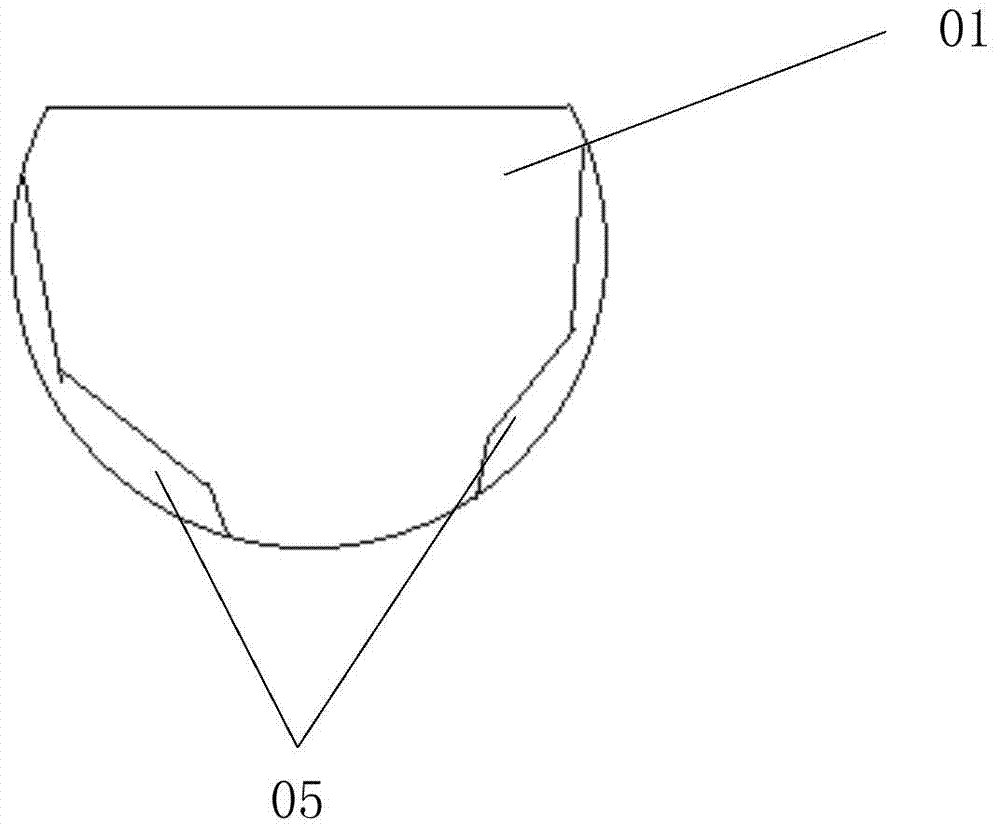

[0037] The present invention aims at the problem that apparent defects such as color difference, water marks, and film frame marks are easily formed on the back of the silicon wafer when performing silicon etching in a simple acid bath in the prior art, and provides a method for etching silicon on the back of the acid bath. Process flow, modification of the frame structure, increasing nitrogen bubbling and improving the flushing method, so that the silicon corrosion on the back of the simple acid tank meets the quality requirements, and reduces the possibility of color difference, water marks, and frame marks on the back of the silicon wafer. and improve the economic efficiency of production.

[0038] Such as Figure 9 As shown, the embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com