Motor driving device with fault tolerance function

A technology of motor drive and fault tolerance function, which is applied in the direction of AC motor control, electrical components, control systems, etc., and can solve problems such as high magnetic field weakening rate, low speed and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

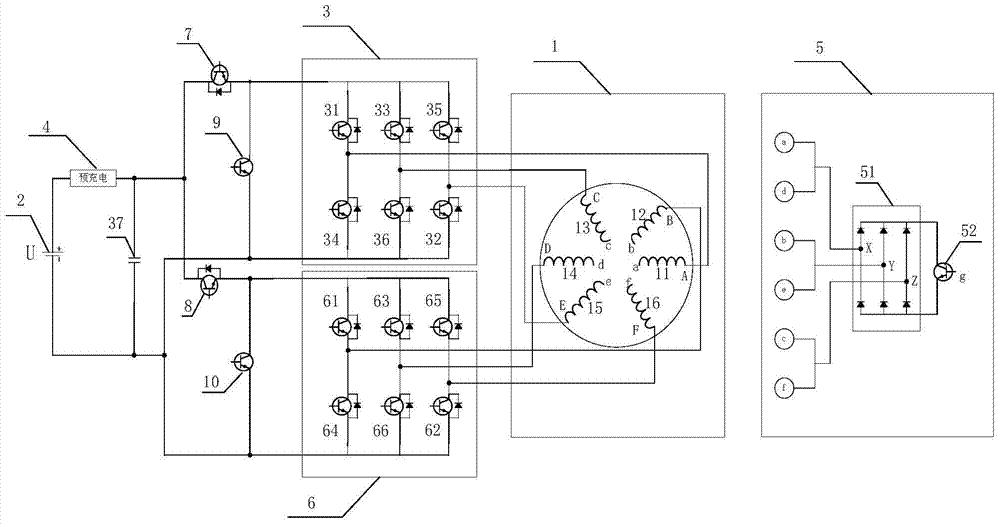

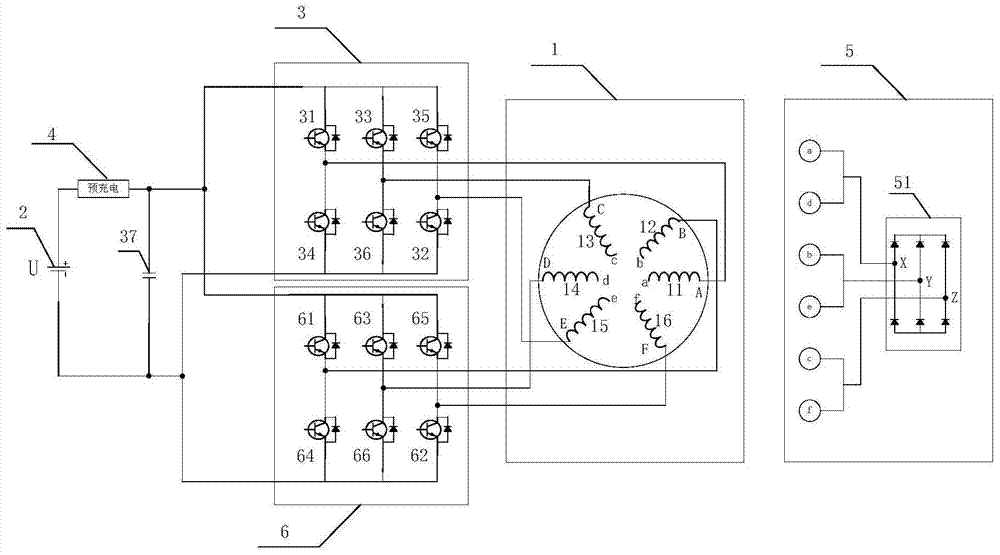

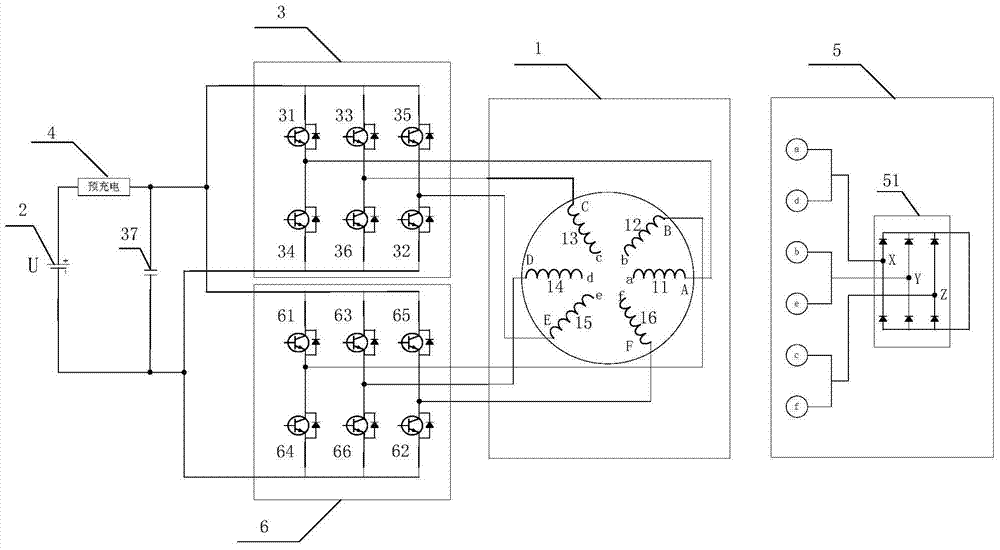

[0026] Such as figure 1 As shown, the motor drive device with fault-tolerant function of the present invention at least includes a permanent magnet motor 1, a battery pack 2, two three-phase inverters 3, 6, a pre-charging circuit 4, a short-circuit device 5, four IGBT modules 7 , 8 , 9 , 10 and a capacitor 37 . The first three-phase inverter 3 includes a first IGBT module 31, a second IGBT module 32, a third IGBT module 33, a fourth IGBT module 34, a fifth IGBT module 35 and a sixth IGBT module 36; the second The three-phase inverter 6 includes an eleventh IGBT module 61, a twelfth IGBT module 62, a thirteenth IGBT module 63, a fourteenth IGBT module 64, a fifteenth IGBT module 65 and a sixteenth IGBT module 66; The magneto 1 includes a first winding 11, a second winding 12, a third winding 13, a fourth winding 14, a fifth winding 15 and a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com