Iron mineral liquid magnetized separating vibrating screen system, liquid magnetized separating device and separating method

A sorting device and iron ore technology, applied in chemical instruments and methods, magnetic separation, filtering and screening, etc., can solve the problems of hematite over-grinding and increase the difficulty of process sorting, so as to reduce inclusions and achieve selectivity Effect of separation and improvement of concentrate quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

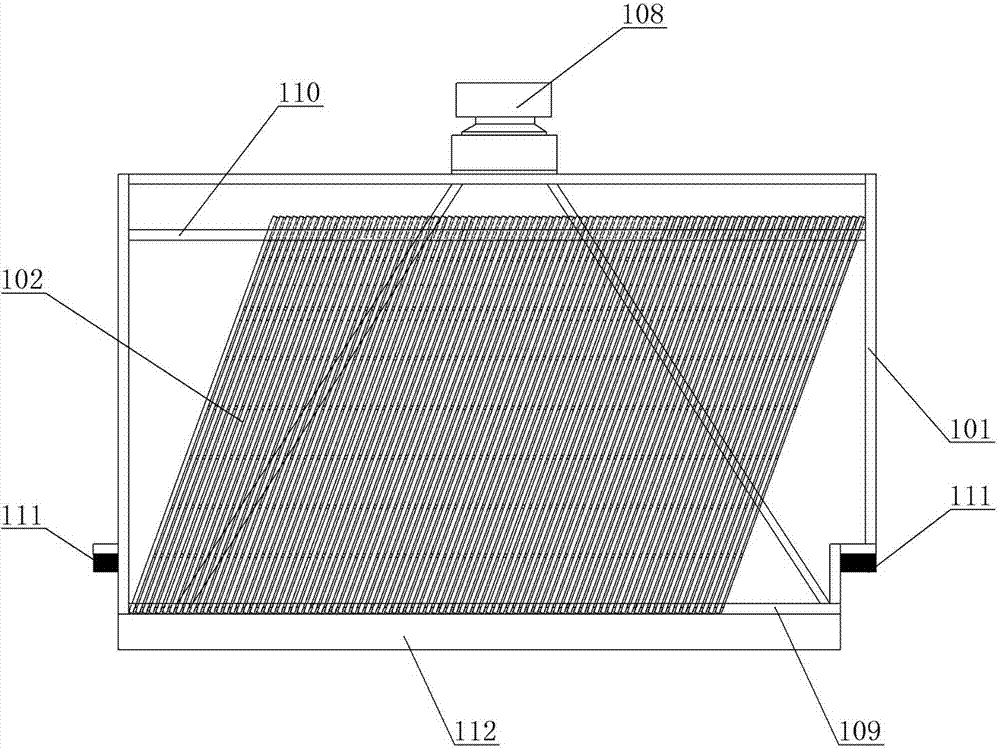

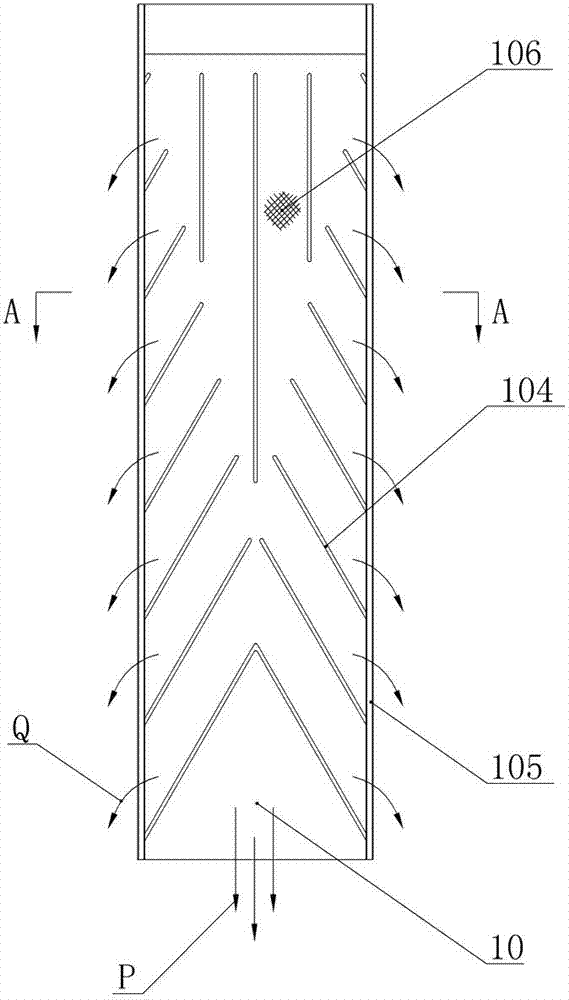

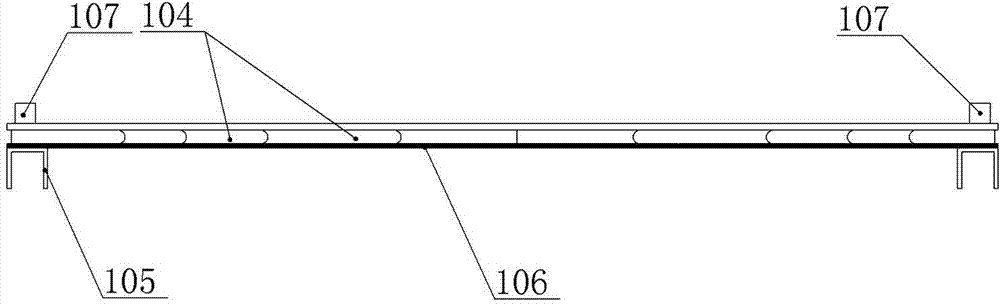

[0031] Example 1: see Figure 1-Figure 4 , A vibrating screen system for iron mineral liquid magnetization sorting, comprising a screen system fixed frame 101 and an array of screen unit 102 arranged in a horizontally inclined stack arranged in the screen system fixed frame 101, the screen unit 102 includes The sieve plate 103, a plurality of middle ore diversion ribs 104 and screens 106 which are arranged vertically arranged on one side of the sieve plate 103 and opened in a figure eight shape. The screens 106 are pressed by groove-shaped bead 105. The outer end of the middle mine guide bar 104 is fixed by screws. The outer end of the middle mine guide bar 105 intersects the outer edge of the sieve plate 103. The other sieve plate 103 corresponding to the screen 106 The two longitudinal edges of the side are provided with longitudinal ribs 107, and the longitudinal ribs 107 of the adjacent two screen units 102 and the groove-shaped bead 105 are matched and connected in a snap-f...

Embodiment 2

[0035] Example 2: see Figure 1-Figure 9 , A liquid magnetization separation device using the vibrating screen system described in Embodiment 1, comprising a support frame 2, a vibrating screen system 1 matched and placed in the support frame 2, and a vibrating screen fixed on the support frame 2 and correspondingly provided It is the magnetized magnetic system on both sides. The support frame 2 is a cylindrical structure with an open top, bottom and sides. The bottom section of the support frame 2 gradually shrinks. The top of the support frame 2 is provided with a vibrating screen system. 1 Corresponding feeding mechanism, the lower part of the support frame 2 is provided with a concentrate bin and a middle ore bin corresponding to the vibrating screen system 1, and the bottom of the concentrate bin and the middle ore bin are respectively provided with a concentrate discharge port 202 and a middle ore discharge Port 201, the magnetized magnetic system includes two planar magne...

Embodiment 3

[0038] Example three: see Figure 1-Figure 6 , Picture 10 , Picture 11 The structure of this embodiment is basically the same as that of the second embodiment, and the similarities will not be repeated. The difference is that a plurality of sorting units of the vibrating screen system 1 are arranged in the support frame, and there are The sorting units are independent of each other. The lower and upper parts of each sorting unit are provided with a concentrate bin, a middle ore bin and a feeding mechanism that match the vibrating screen system, thereby increasing its sorting efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com