Automatic tripping device for push-pull trolley for working roll changing

A technology of automatic decoupling and pushing and pulling of carts, which is applied in the fields of manufacturing tools, metal processing equipment, metal rolling, etc., can solve the equipment failure rate, difficulty in post-maintenance equipment costs, increased energy consumption, increased equipment structure complexity, and low automation. and other problems, to achieve the effect of saving driving energy, compact structure and simplified equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

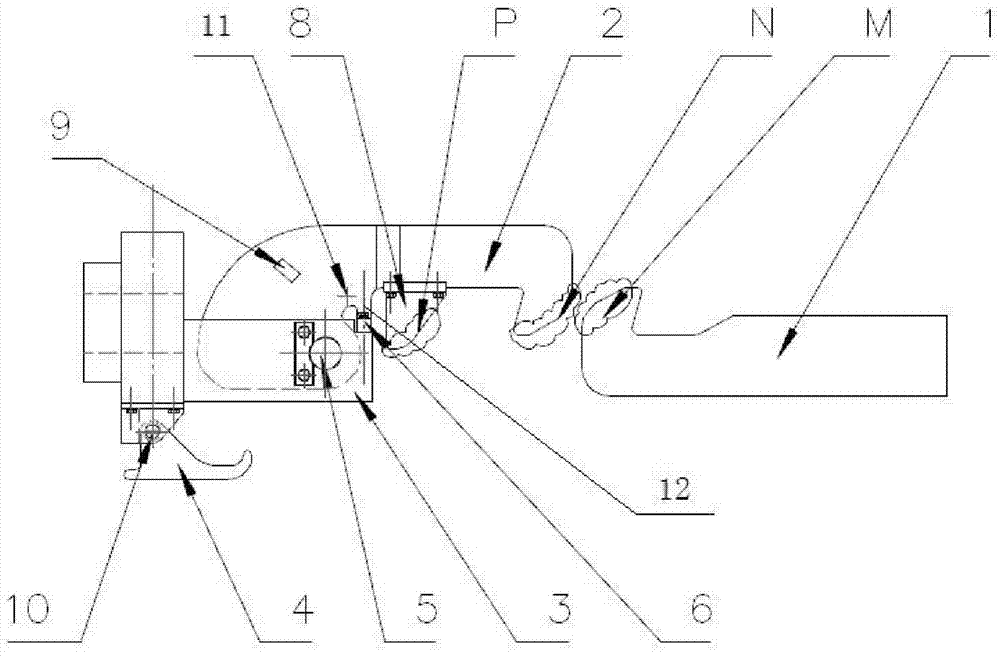

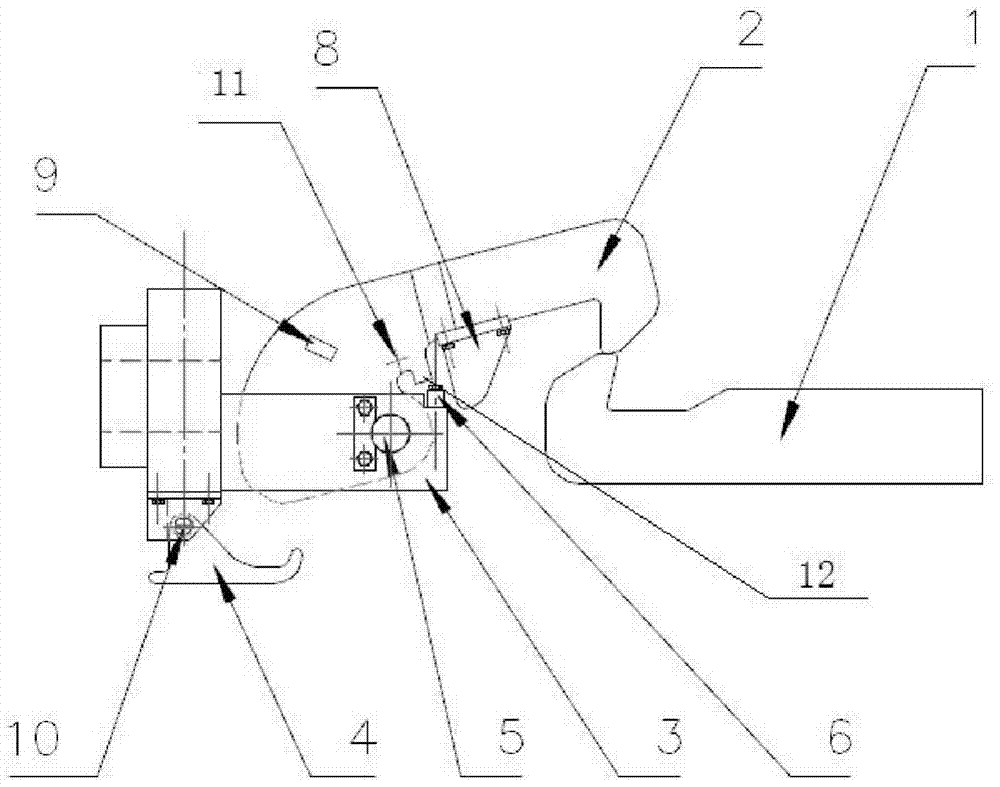

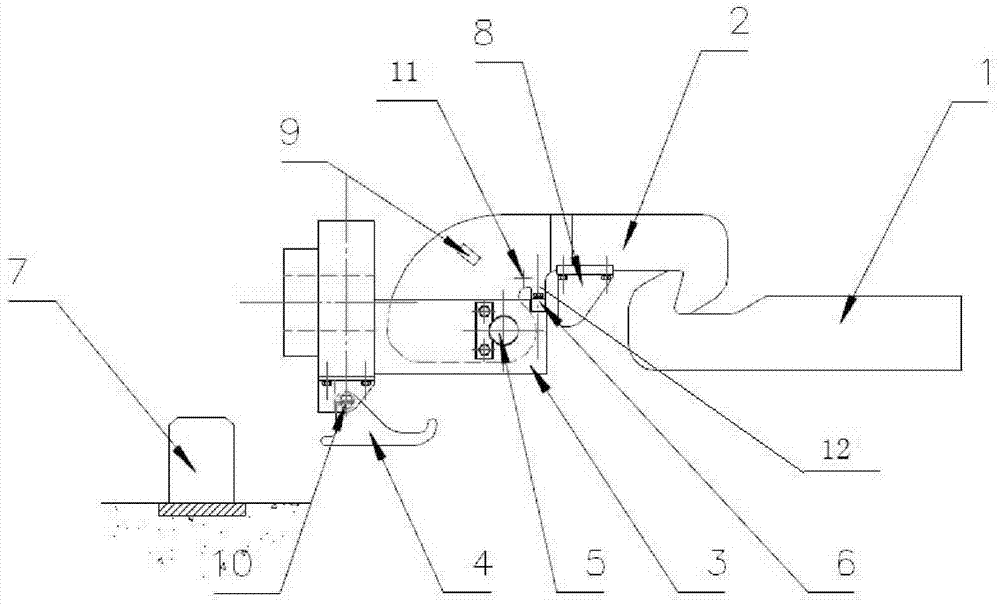

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0022] Such as Figure 1-7 As shown, an automatic uncoupling device for a work roll changing push-pull cart, comprising a roll-changing trolley coupler 1, a push-pull trolley coupler 2, a push-pull trolley frame 3, a push-pull trolley stop 7, the push-pull trolley coupler 2 and the push-pull trolley frame 3. Hinged connection. During work, the push-pull trolley and the roller changing trolley are connected with the push-pull trolley coupler 2 through the roller-changing trolley coupler 1, and the push-pull trolley stopper 7 is fixed on the ground or other relatively stationary objects with the push-pull trolley frame 3; The top surface M of the hook head of the small roller changing coupler 1 is a smooth curved slope, and the top surface N of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com