Efficient cable material squeezing wrapping machine head

A technology of cable material and machine head, applied in the direction of coating, etc., can solve the problems of high cost, complex structure, troublesome disassembly and maintenance, etc., and achieve the effect of low cost, safe operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

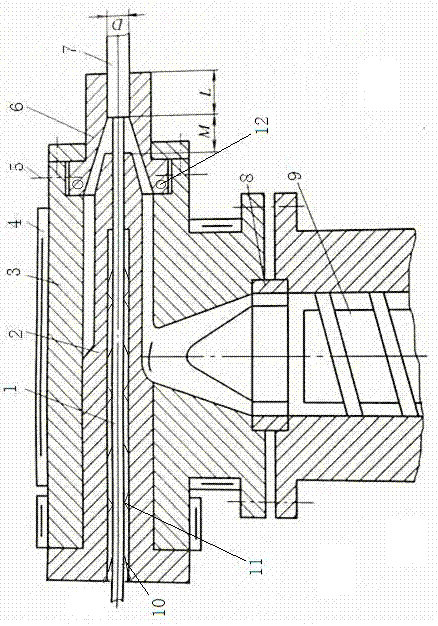

[0016] Example 1 : see figure 1 , a high-efficiency cable material extrusion coating head, the coating head includes a head body 3, a die 6 arranged at one end of the head body, a guide rod 2 is arranged inside the head body, and the guide rod 2. A core wire 1 is arranged in the middle, and a coating plastic part 7 is arranged on the outside of the die. The coating head also includes a perforated plate 8, and the porous plate 8 is arranged under the head body 3. The guide rod 2 is provided with a shunt sleeve 10 and a pressure equalizing ring 11. The number of the shunt sleeve 10 and the pressure equalizing ring 11 is at least one. The shunt sleeve 10 ensures that the plastic flow path in the machine head is reasonable and eliminates The dead angle of accumulated plastic; the pressure equalizing ring eliminates the pressure fluctuation during plastic extrusion. The structure design of the whole technical scheme is ingenious and compact, which ensures that the plastic flow c...

Embodiment 2

[0017] Example 2 : see figure 1 As an improvement of the present invention, the coating head further includes an electric heater, which is arranged above the head body to properly heat the head body to further ensure the quality of the product. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0018] Example 3 : see figure 1 , as an improvement of the present invention, the coating head also includes an adjustment screw, the adjustment screw is arranged on the die, and the adjustment screw is used to adjust the tension of the die, while ensuring the die and the core Concentricity. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com