Pencil sharpening mechanism and pencil sharpener with same

A chip sweeping and knife holder technology, applied in sharpening devices, printing, office supplies, etc., can solve the problems of increasing the load of the rocker arm, affecting the rotation of the hob, hindering the rotation of the gear, and achieving the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

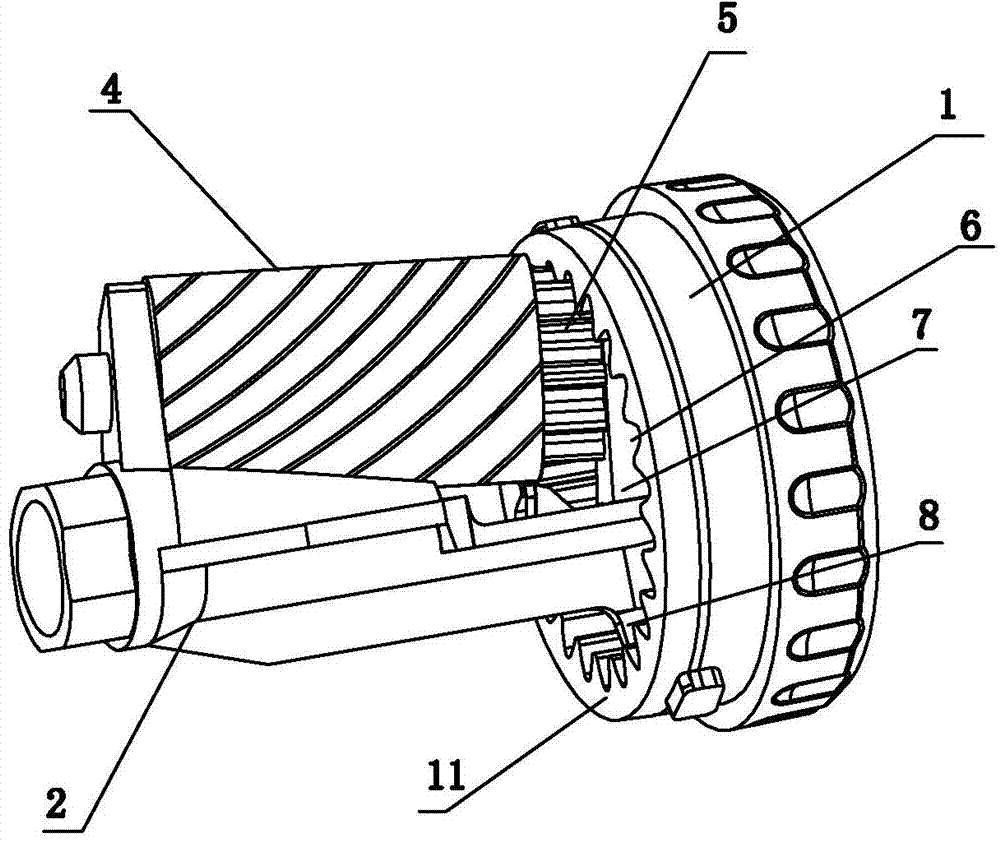

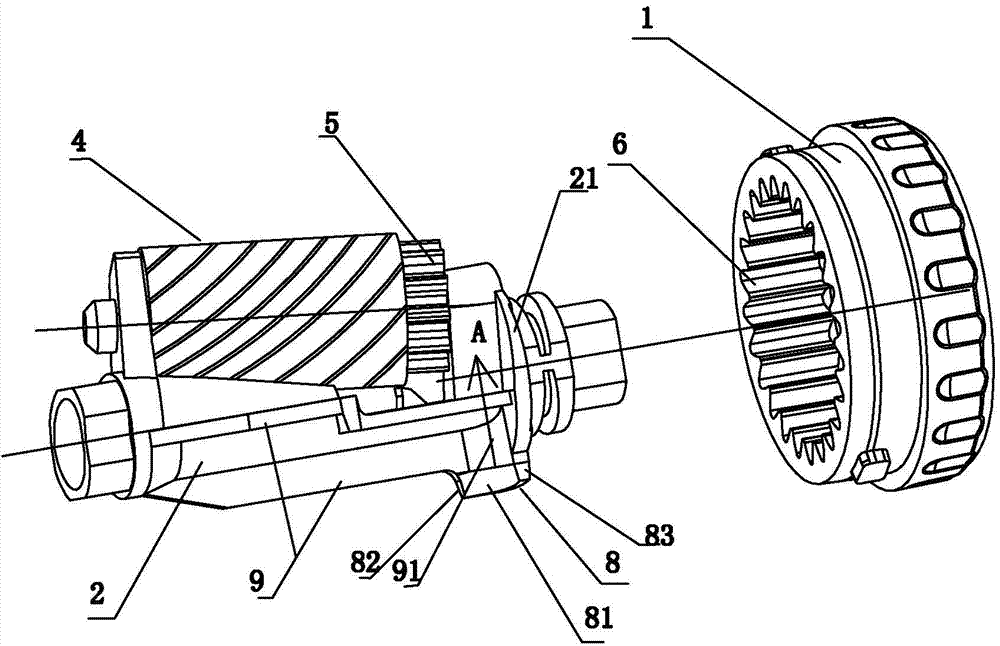

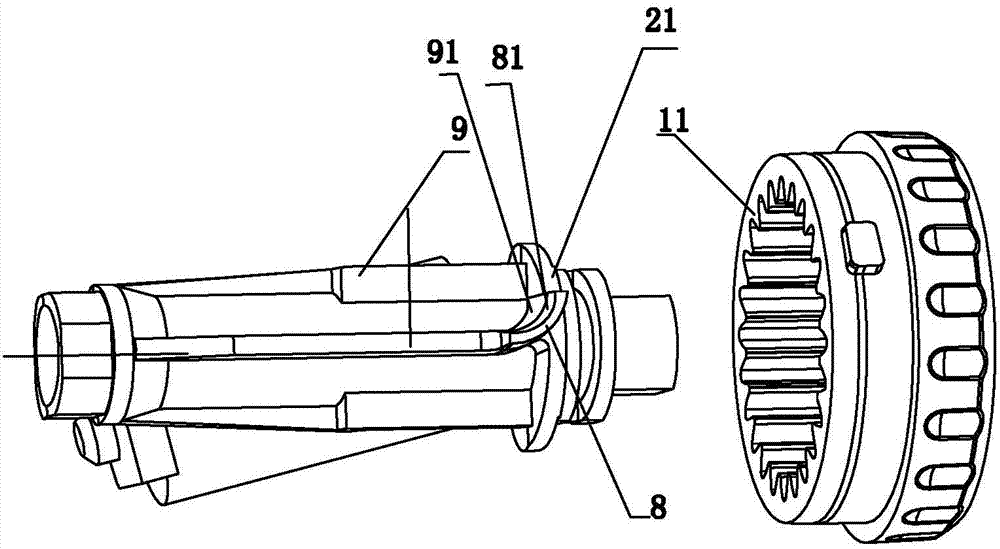

[0018] Such as figure 1 , figure 2 with image 3 Shown; a pencil sharpening mechanism and a pencil sharpener including the following technical features, including a rotating wheel seat 1, a knife holder 2 driven by a rocker arm, and a hob 4 mounted on the knife holder 2, on one end of the hob 4 The gear 5 meshes with the internal gear 6 of the runner seat 1. One end of the tool holder 2 is installed in the middle of the inner side of the runner seat 1. The inside of the runner seat 1 is provided with a cavity 7 for gear movement. The chip sweeping block 8 extending in the direction of the internal gear 6 is located in the cavity 7.

[0019] The chip sweep block 8 has an arc structure, and the arc direction of the chip sweep block 8 is consistent with the moving direction of the hob 4 on the runner seat 1. figure 2 The direction pointed by the arrow A is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com