Particle sorting device

A particle and sorting technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of a large number of particles, the inability to take into account the inspection efficiency and inspection accuracy at the same time, and the disorganized spread.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

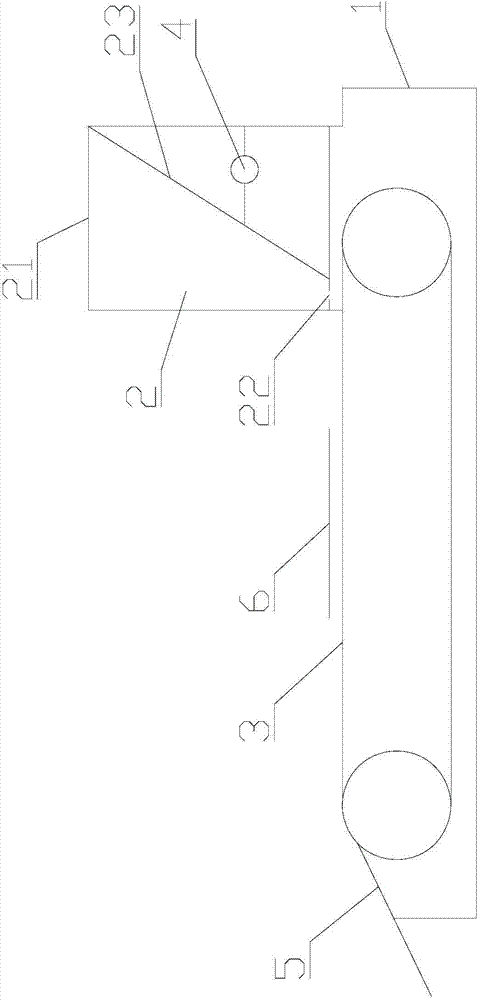

[0015] Such as figure 1 As shown, a particle sorting device includes a frame 1, a conveying mechanism, a silo 2, a vibrating mechanism 4, a magnifying glass panel 6 and a blanking plate 5, and the conveying mechanism and the silo are respectively installed on the frame.

[0016] The conveying mechanism has a horizontal working surface 3. In this embodiment, the conveying mechanism includes a motor, a driving wheel, a driven wheel, a synchronous belt and a frequency converter. The motor drives the driving wheel to rotate, and the driving wheel and the driven wheel pass through The synchronous belt drive connection, the driving wheel and the driven wheel are located at the same level, the upper surface of the synchronous belt is the working surface of the conveying mechanism, the motor is electrically connected to the frequency converter, and the frequency converter is wirelessly connected to a remote controller. Of course, a horizontal support surface can also be directly arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com