A multi-functional and efficient dry bulk cargo reloading integrated equipment and its control method at sea

A dry bulk, multi-functional technology, applied in the field of multi-functional and efficient dry bulk cargo reloading integration equipment and systems at sea, can solve the problems of unguaranteed stability and low transfer efficiency, and achieve safety and continuity. Inefficient, Adaptable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

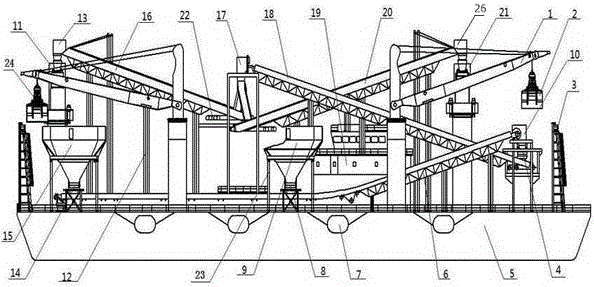

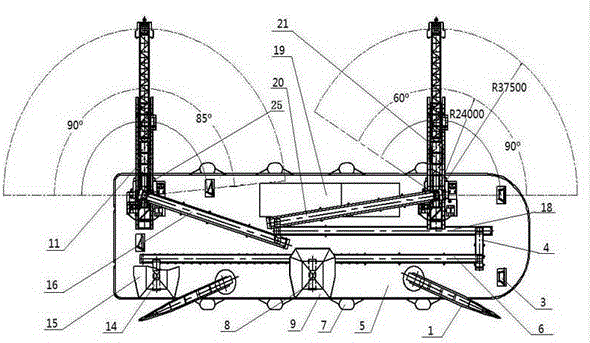

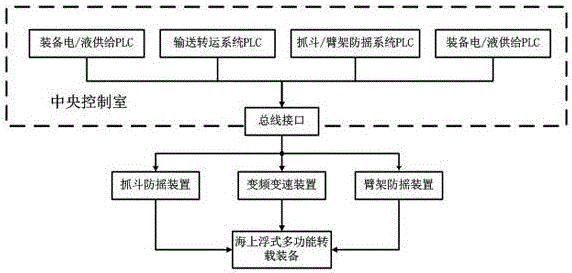

[0029] Such as figure 1 As shown, the present invention is a multi-functional and high-efficiency dry bulk cargo reloading integrated equipment and system at sea. On the floating platform 5, there are not only grab ship unloaders and ship loaders for loading and unloading, but also feeding belt conveyors for conveying operations. , belt conveyor and reloading belt conveyor, the conveying and transshipment system and its support system and other devices, and also has a PLC control system integrated in the central control room 19, including PLC for electric / hydraulic supply system, grab / arm frame anti-sway system PLC, conveyor transfer system PLC and ship loader transfer system PLC. They provide the working power of the equipment, ensure the overall balance of the equipment and the continuous high efficiency of operation, real-time monitoring and troubleshooting function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com